Tel:

+8618931101301

Tel:

+8618931101301

Δεκ . 01, 2024 07:38 Back to list

High-Quality Stainless Steel Filter Cartridges for Efficient Filtration Solutions

Understanding Stainless Steel Filter Cartridges A Comprehensive Guide

In various industrial and commercial applications, the need for efficient filtration is paramount. Among the numerous filtration options available today, stainless steel filter cartridges stand out due to their durability, effectiveness, and versatility. This article will explore what stainless steel filter cartridges are, their benefits, applications, and maintenance practices.

What Are Stainless Steel Filter Cartridges?

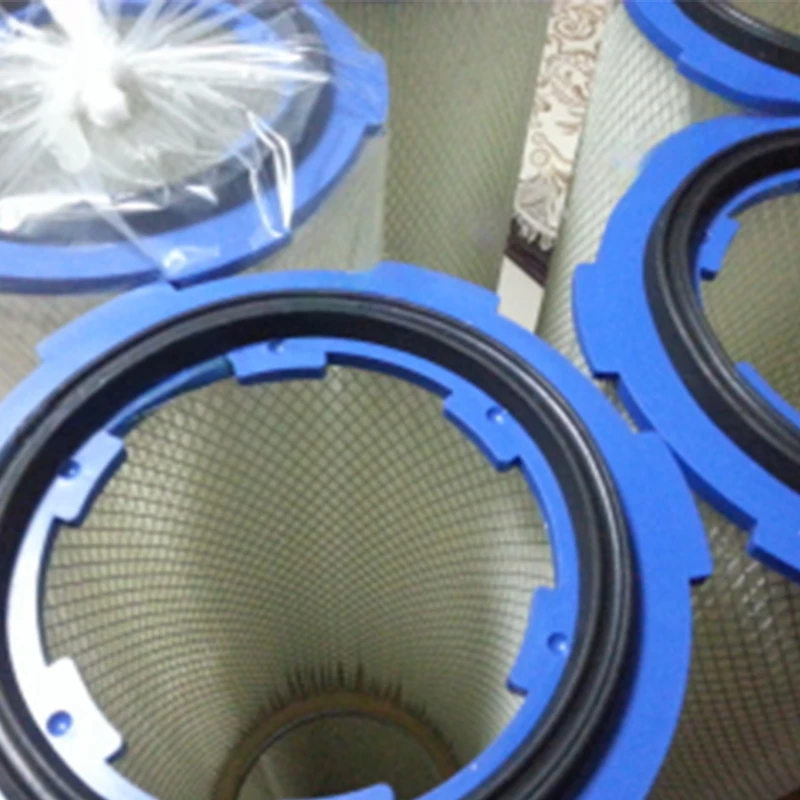

Stainless steel filter cartridges are cylindrical filters made from stainless steel material. They are designed to remove impurities, sediments, and contaminants from liquids and gases in various systems. The construction typically includes a perforated stainless steel shell with a filter media inside, which can range from woven mesh to non-woven materials, depending on the specific filtration needs.

Benefits of Stainless Steel Filter Cartridges

1. Durability One of the primary advantages of stainless steel is its resistance to corrosion and rust. This property allows stainless steel filter cartridges to withstand harsh environments and a wide range of temperatures, making them suitable for both high and low-pressure settings.

2. Reusability Unlike disposable filters, stainless steel cartridges can often be cleaned and reused. This feature not only reduces waste but also lowers long-term operational costs. Users can simply backflush or clean the cartridges depending on the level of contamination, extending their lifespan.

3. High Filtration Efficiency Stainless steel filters offer superior filtration capabilities. They can effectively remove particulate matter from fluids, ensuring that the final output is clean and free from impurities. This is especially important in industries where product purity is critical, such as pharmaceuticals and food processing.

4. Versatility These filter cartridges can be designed for various applications and can accommodate different pore sizes to achieve desired filtration levels. They are effective for applications ranging from water treatment to oil and gas industries.

5. Chemical Resistance Stainless steel can withstand a variety of chemicals, making these filter cartridges suitable for use in aggressive environments where other materials might fail.

Applications of Stainless Steel Filter Cartridges

stainless filter cartridge

Stainless steel filter cartridges find widespread use across multiple industries, including

- Pharmaceuticals Ensuring the integrity and safety of products by filtering out contaminants before they enter production lines. - Food and Beverage Maintaining the quality of consumable products by filtering impurities from liquids such as juices, beers, and water. - Chemical Processing Protecting machinery and ensuring product quality by removing particulate matter from raw materials and reagents. - Oil and Gas Filtering out sand, dirt, and other contaminants from crude oil and other petroleum products to refine and transport them safely.

Maintenance of Stainless Steel Filter Cartridges

Proper maintenance is crucial to ensuring the longevity and effectiveness of stainless steel filter cartridges. Here are key maintenance practices

1. Regular Inspection Periodically inspect filter cartridges for signs of wear or damage. Look for corrosion, deformities, or clogs that may indicate the need for cleaning or replacement.

2. Cleaning Process Depending on the type of contamination, stainless steel cartridges can be cleaned using various methods, including backwashing, chemical cleaning, or ultrasonic cleaning. It is essential to follow the manufacturer's guidelines for effective cleaning without damaging the filter.

3. Replacement If cleaning does not restore performance, it may be time to replace the filter cartridge. Additionally, ensure regular replacement of any seals and O-rings that may degrade over time.

4. Monitoring Performance Keeping track of flow rates and pressure differentials can provide insight into the filter's condition, helping to preemptively identify issues before they escalate.

Conclusion

Stainless steel filter cartridges represent a reliable and efficient solution for a wide range of filtration needs across different industries. Their durability, reusability, and high filtration efficiency make them an excellent choice for any application where cleanliness and safety are priorities. By understanding the benefits, applications, and maintenance needs of these filters, users can ensure optimal performance and longevity, contributing to the efficiency of their operations. As industry standards continue to rise, investing in quality filtration solutions like stainless steel filter cartridges is more critical than ever.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: