Tel:

+8615930870079

Tel:

+8615930870079

Δεκ . 02, 2024 06:35 Back to list

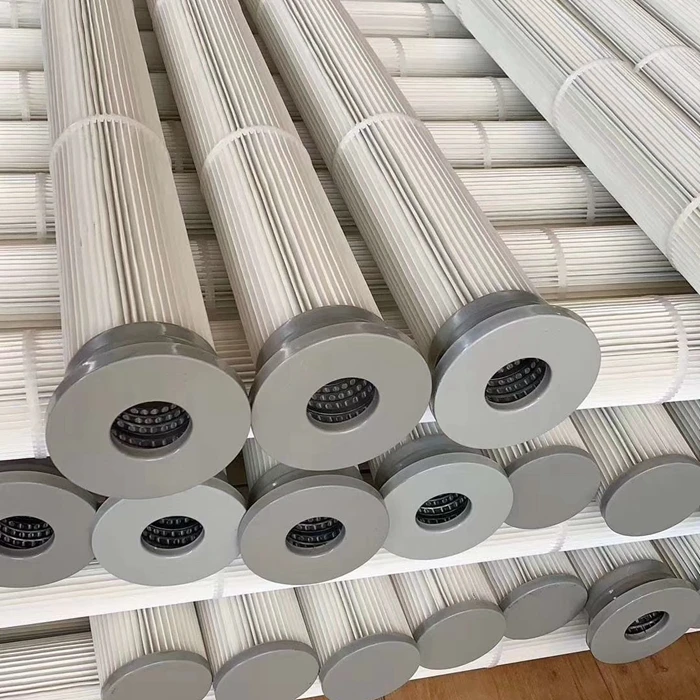

ss pleated filter cartridge

The Importance of SS Pleated Filter Cartridges in Industrial Filtration

In various industrial processes, the quality of fluids used directly impacts the efficiency and lifespan of machinery and equipment. One critical component that ensures the cleanliness of these fluids is the filter cartridge. Among various types of filter media available, stainless steel (SS) pleated filter cartridges stand out due to their effectiveness, durability, and versatility.

What are SS Pleated Filter Cartridges?

Stainless steel pleated filter cartridges are filtering devices made from high-quality stainless steel, which is known for its excellent corrosion resistance, strength, and longevity. The pleated design increases the surface area available for filtration, allowing for higher dirt-holding capacity and longer service life compared to traditional filters. The pleating also enhances the flow rate, ensuring that processes are not hindered by excessive backpressure.

Key Advantages of SS Pleated Filter Cartridges

1. Durability and Longevity Stainless steel is inherently robust and resistant to the corrosive effects of various chemicals, making SS pleated filter cartridges suitable for harsh environments. They can withstand high temperatures and pressures, significantly extending the intervals between replacements.

2. High Dirt-Holding Capacity The pleated design allows for a greater surface area, which means these cartridges can trap more particulates before needing replacement. This feature reduces downtime for maintenance and enhances overall operational efficiency.

3. Cost Efficiency Although the initial investment for stainless steel filters may be higher than for disposable alternatives, the long-term savings are substantial. The durability reduces replacement frequency, and the lack of consumable components minimizes waste and disposal costs.

ss pleated filter cartridge

4. Reusability Stainless steel cartridges can often be cleaned and reused, further contributing to their cost-effectiveness. Many industries favor this characteristic as it supports sustainability efforts by reducing material waste.

5. Versatility SS pleated filter cartridges can be used in a wide range of applications, including water treatment, food and beverage processing, pharmaceuticals, and petrochemicals. They can filter out various contaminants, from suspended solids to larger particulates, thus ensuring fluid purity across different industries.

Applications of SS Pleated Filter Cartridges

The versatility of SS pleated filter cartridges makes them ideal for various sectors

- Water and Wastewater Treatment They are commonly used to screen out sediments and pollutants from water, ensuring compliance with environmental regulations. - Food and Beverage Industry The filters help maintain the quality and safety of food products by removing unwanted particulates without affecting the taste or odor. - Pharmaceutical Production Cleanliness is critical in this sector. SS pleated filters enable the removal of contaminants to ensure that products meet strict regulatory standards. - Oil and Gas Industry They are employed to filter crude oil, ensuring the removal of particulate matter that can damage equipment and affect product quality.

Conclusion

In conclusion, SS pleated filter cartridges represent a superior choice for industrial filtration needs due to their durability, high dirt-holding capacity, cost efficiency, and versatility. As industries continue to prioritize efficiency and sustainability, the demand for advanced filtration solutions will undoubtedly grow. By integrating stainless steel pleated filter cartridges into their operations, businesses can ensure cleaner processes, reduce maintenance costs, and contribute to a more sustainable future. As technology evolves, the importance of high-performance filtration solutions like SS pleated filters will only increase, making them an essential component in various industrial applications. Whether in water treatment, manufacturing, or pharmaceuticals, the implementation of high-quality filtration systems is key to operational success and product integrity.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: