Tel:

+8618931101301

Tel:

+8618931101301

Δεκ . 15, 2024 01:39 Back to list

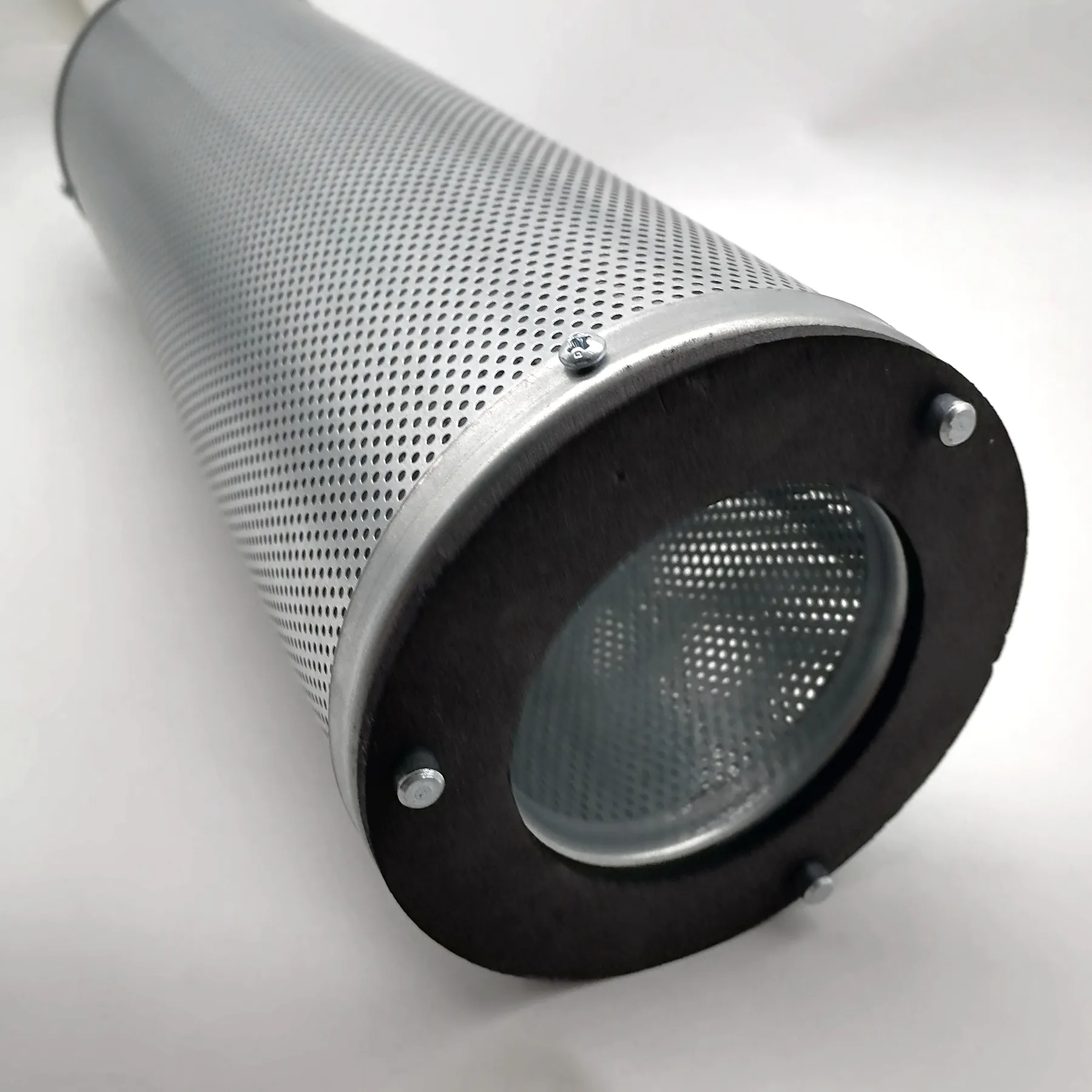

High Efficiency Sintered Stainless Steel Filter Cartridges for Industrial Applications

Understanding Sintered Stainless Steel Filter Cartridges

Sintered stainless steel filter cartridges are essential components in various filtration systems, renowned for their durability, efficiency, and versatility. These cartridges are manufactured through a process called sintering, which involves heating stainless steel powder to just below its melting point, allowing the particles to fuse together. This process results in a porous structure capable of effectively filtering out contaminants from liquids or gases.

One significant advantage of sintered stainless steel filter cartridges is their high permeability and excellent flow rates. The porous nature of the material allows fluids to pass through with minimal resistance while effectively trapping solid particles. This characteristic makes them ideal for applications in industries such as chemical processing, pharmaceuticals, oil and gas, food and beverage, and water treatment.

Understanding Sintered Stainless Steel Filter Cartridges

Furthermore, sintered stainless steel filter cartridges are highly customizable. They can come in various shapes, sizes, pore sizes, and filtration grades tailored to meet specific requirements. Whether one needs a coarse filter for initial separation or a fine filter for high-precision applications, sintered stainless steel filters can be designed accordingly. This versatility makes them suitable for both liquid and gas filtration processes.

sintered ss filter cartridges

Maintenance is another aspect where sintered stainless steel filter cartridges shine. Due to their durable construction, these filters can often be cleaned and reused, reducing waste and operational costs. Common cleaning methods include backwashing, ultrasonic cleaning, or chemical cleaning, depending on the type of contaminants collected. This longevity not only extends the life of the filter but also contributes to a more environmentally friendly operation.

Moreover, the applications of sintered stainless steel filter cartridges are vast. In the chemical industry, they are used for the filtration of corrosive substances. In food and beverage processing, they ensure the purity and safety of products by removing unwanted particles. In water treatment, they help in the clarification process, producing clean, safe water for consumption and industrial use. The oil and gas sector also benefits from these filters, where they play a crucial role in separating impurities and maintaining fluid quality.

Sintered stainless steel filter cartridges also offer exceptional thermal stability. They can withstand extreme temperatures, making them suitable for processes that involve heating or cooling. This characteristic is particularly beneficial in industries like aerospace and automotive, where thermal variations can be significant.

In summary, sintered stainless steel filter cartridges are indispensable in numerous industrial sectors due to their effective filtration capabilities, mechanical strength, and adaptability. Their ability to handle various contaminants while being easy to maintain and reusable makes them a cost-effective solution in the long run. As industries continue to prioritize efficiency and sustainability, the role of sintered stainless steel filters will undoubtedly grow, proving their value in maintaining clean, safe, and reliable operations.

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

Email:

Email: