Tel:

+8618931101301

Tel:

+8618931101301

Δεκ . 24, 2024 19:56 Back to list

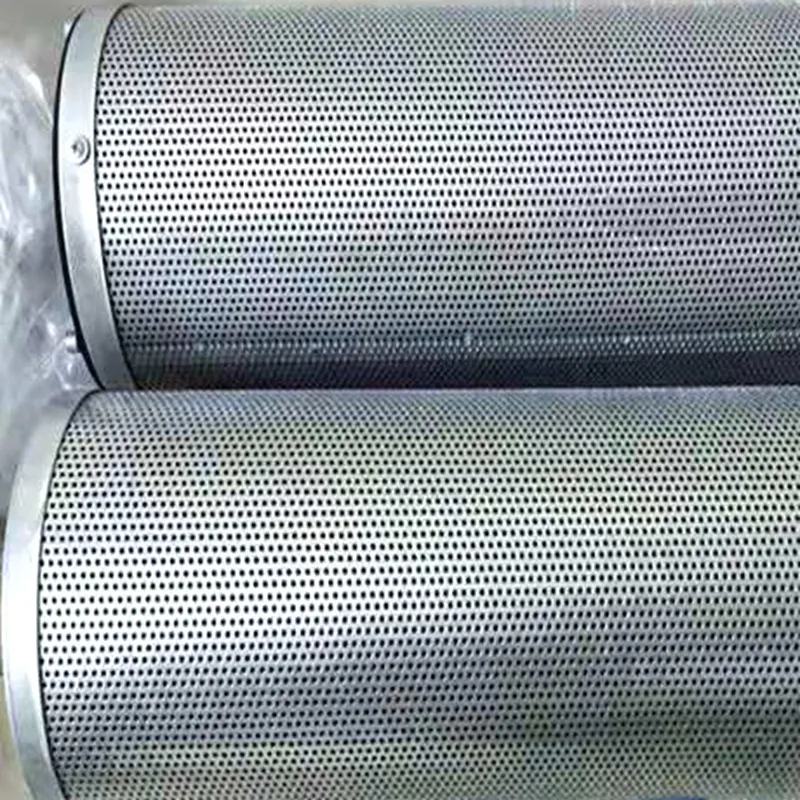

silo filter cartridge

Understanding Silo Filter Cartridges Essential Components for Efficient Industrial Filtration

In various industrial applications, maintaining the quality of processed materials is crucial for both operational efficiency and product integrity. One of the key components in achieving this is the silo filter cartridge. These cartridges play an essential role in filtration systems, particularly in industries that handle bulk materials, such as food processing, pharmaceuticals, chemicals, and construction materials. In this article, we will explore the importance of silo filter cartridges, their functioning, types, and best practices for maintenance.

What Are Silo Filter Cartridges?

Silo filter cartridges are specialized filtration devices designed to remove contaminants from the air and materials in silo storage systems. They are typically used to prevent the ingress of dust and particulates into the storage silo, thereby keeping the stored materials clean and ensuring compliance with health and safety regulations. In addition to protecting the quality of the bulk materials, these cartridges also help in maintaining the overall environment by minimizing dust emissions, which can be harmful to both workers and the surrounding environment.

How Do Silo Filter Cartridges Work?

The functionality of a silo filter cartridge is based on the principle of mechanical filtration. As air or material enters the silo, it passes through the filter cartridge, which captures particles and impurities. The filter media, which can be made from a variety of materials such as polymer, polyester, or other synthetic fabrics, is designed with specific pore sizes to achieve optimal filtration efficiency.

When the filter cartridge is subjected to airflow, particles are trapped on the surface or within the depth of the filter media. Over time, as more particles are collected, the filter becomes saturated, and its efficiency can decrease. This is why regular maintenance and replacement are critical to ensure that the system continues to operate effectively.

Types of Silo Filter Cartridges

There are several types of silo filter cartridges available, each suited to specific applications and environments

1. Bag Filters These are made from fabric and are suitable for lower pressure applications. They have a large surface area, allowing them to capture a significant amount of dust before needing replacement.

2. Pleated Filters Characterized by their accordion-like structure, pleated filters provide a large filtration area in a compact design. They are efficient at capturing fine dust particles and are ideal for applications where space is limited.

silo filter cartridge

3. Ceramic Filters These filters are known for their durability and heat resistance. Ceramic filter cartridges are widely used in industries that deal with high temperatures or aggressive chemicals.

4. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture very small particles, making them suitable for environments that require high levels of cleanliness, such as pharmaceutical manufacturing.

Maintenance Best Practices

To maximize the performance and lifespan of silo filter cartridges, proper maintenance is essential. Here are some best practices to consider

- Regular Inspection Periodically check the condition of the filter cartridges for signs of wear, damage, or excessive dust buildup. Early detection of issues can prevent costly downtime and ensure efficient operation.

- Scheduled Replacements Follow the manufacturer’s recommendations for replacement intervals. Replacing filters on a schedule, rather than waiting for a noticeable drop in performance, can help maintain optimal airflow and filtration efficiency.

- Cleaning Procedures In some cases, cartridge filters can be cleaned using compressed air or specialized cleaning equipment. Ensure that the cleaning process does not damage the filter media.

- Proper Installation Ensure that filter cartridges are installed correctly and securely to prevent leaks, which can undermine the filtration process and compromise the quality of the stored materials.

Conclusion

Silo filter cartridges are indispensable components in industrial filtration systems. They ensure the cleanliness of bulk materials, enhance operational efficiency, and protect both employee health and environmental quality. By understanding their function, types, and maintenance, industrial operators can optimize filtration processes and secure the integrity of stored materials. Investing in high-quality filter cartridges and adhering to best practices can lead to significant long-term benefits for any industry reliant on bulk storage and processing.

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

Email:

Email: