Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 24, 2024 11:21 Back to list

pleated filter manufacturers

The Rise of Pleated Filter Manufacturers

In recent years, the demand for effective air and liquid filtration has grown significantly across various industries, catalyzing the rise of pleated filter manufacturers. Pleated filters have become a popular choice due to their enhanced surface area, which significantly increases their efficiency compared to traditional flat filters. This article explores the reasons behind the upward trajectory of pleated filter manufacturers and highlights their contributions to various sectors.

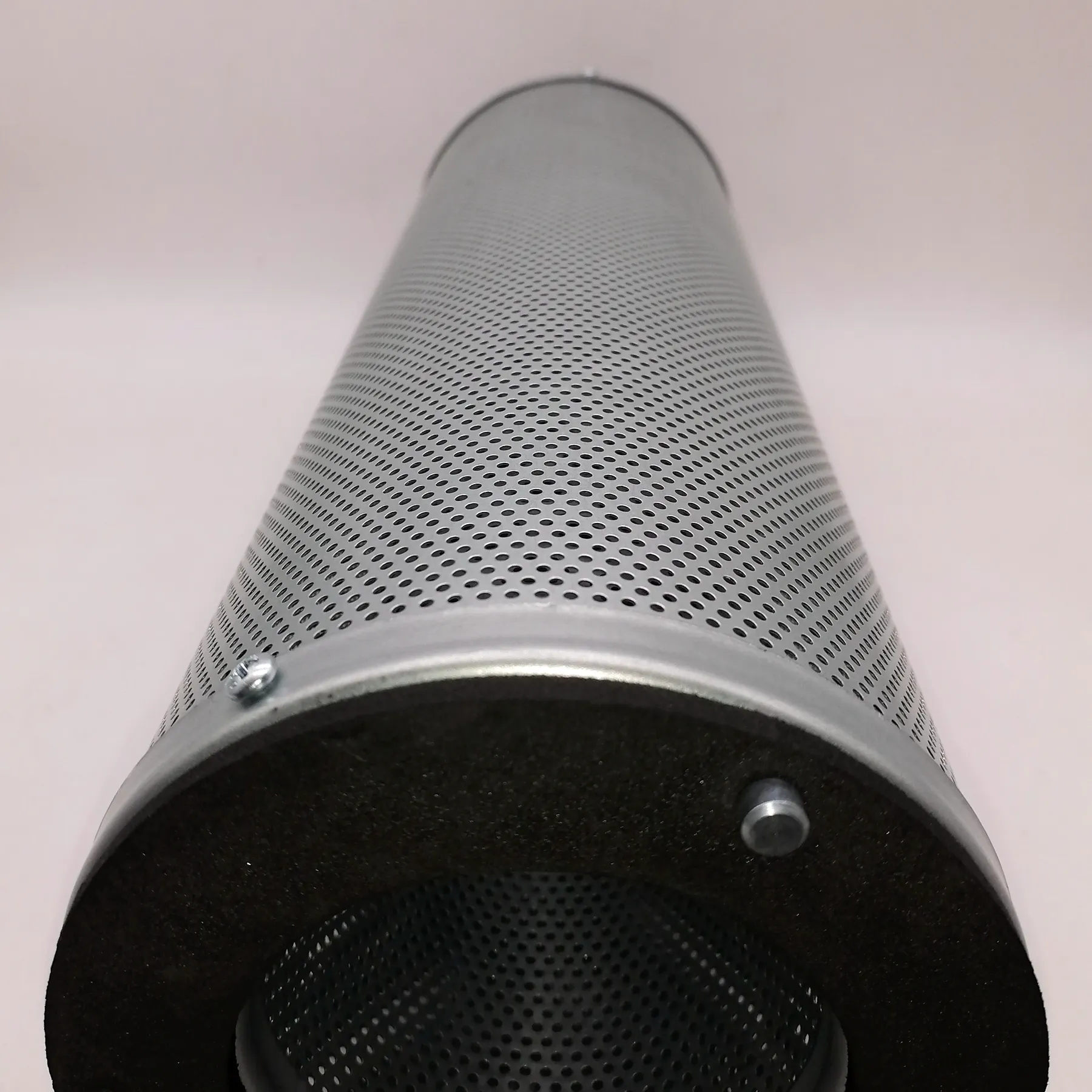

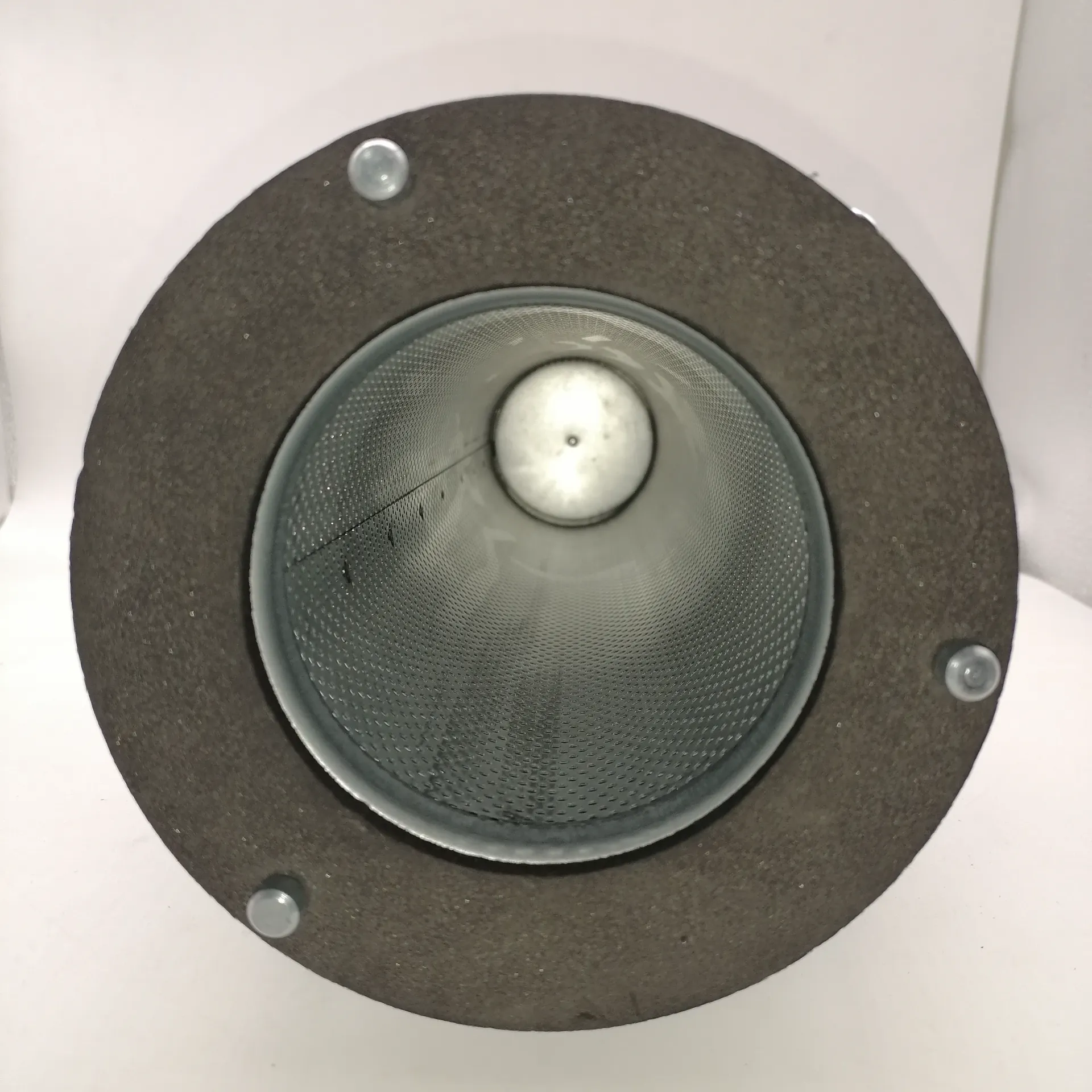

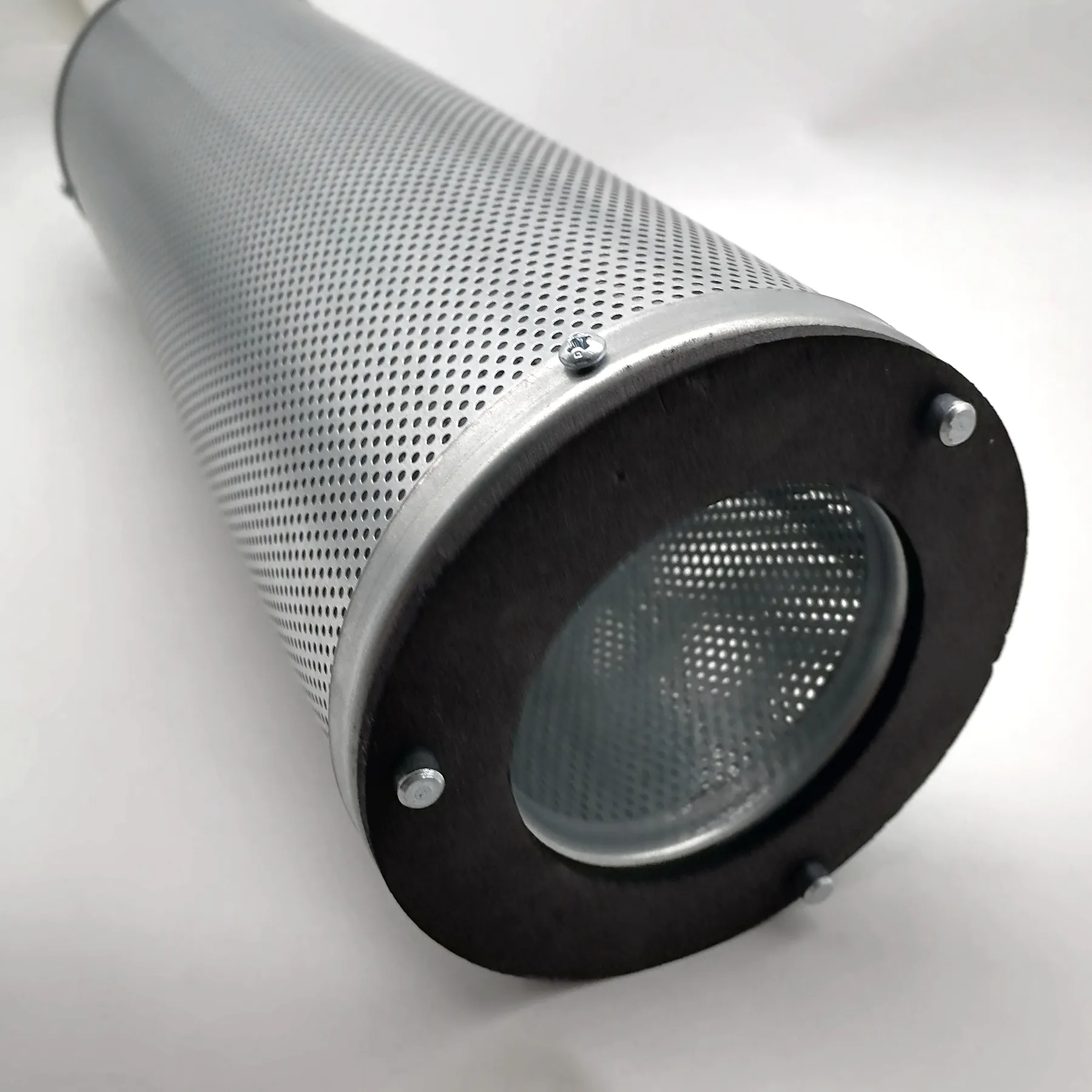

One of the primary advantages of pleated filters is their ability to capture a broader range of particulate matter, which is crucial in maintaining air quality in both industrial and residential settings. The pleating process increases the surface area of the filter media without substantially increasing its size, allowing for greater filtration capacity. This characteristic is particularly beneficial in applications where space is at a premium, such as in HVAC systems, automotive, and industrial equipment. As industries continue to prioritize sustainability and operational efficiency, the demand for high-performance filtration solutions like pleated filters is only expected to rise.

Pleated filter manufacturers are also at the forefront of technological innovation. Many companies have invested significantly in Research and Development (R&D) to produce filter media that not only meet regulatory requirements but also enhance overall performance. Advanced materials such as electrostatically charged fibers increase dust-holding capacity, ensuring longer filter life and reduced maintenance costs for end-users. Innovations in manufacturing processes, including automated production lines and improved folding techniques, further enhance the performance and reliability of pleated filters.

pleated filter manufacturers

Moreover, the increase in environmental regulations worldwide has prompted various sectors, including automotive, food and beverage, pharmaceuticals, and water treatment, to turn to pleated filters for compliance and efficiency. For instance, in the automotive industry, manufacturers are adopting pleated air filters to improve engine performance and reduce emissions. Similarly, in the water treatment sector, pleated filters are essential for ensuring the purity of drinking water by effectively removing contaminants.

The rise of e-commerce has also played a critical role in the growth of pleated filter manufacturers. Online platforms allow manufacturers to reach a global audience, facilitating easier access to their products for consumers and businesses alike. This increased visibility has led to a more competitive market, pushing manufacturers to innovate continually and improve quality.

Furthermore, consumer awareness regarding health and the environment drives demand for high-efficiency particulate air (HEPA) filters and similar technology, further benefitting pleated filter manufacturers. As more consumers seek out home air purification systems, manufacturers are responding with filters that are optimized for residential use without sacrificing effective filtration capabilities.

In conclusion, the landscape of pleated filter manufacturing is more robust than ever, driven by industry demands, technological advancements, and changing consumer preferences. The emphasis on efficiency, sustainability, and compliance with environmental regulations ensures that pleated filters will remain a vital component in various applications. As manufacturers continue to innovate and improve their offerings, the future of pleated filtration looks promising, paving the way for cleaner air, safer liquids, and a healthier planet.

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

Email:

Email: