Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 19, 2024 12:50 Back to list

Optimizing Performance with High-Efficiency Metal Filter Elements for Various Applications

The Importance of Metal Filter Elements in Industrial Applications

Metal filter elements have become increasingly prominent in various industrial applications due to their durability, efficiency, and versatility. These filters play a crucial role in ensuring the purity of fluids and gases, making them indispensable in diverse sectors such as oil and gas, pharmaceuticals, food and beverage, and water treatment.

One of the primary advantages of metal filter elements is their high resistance to temperature and pressure. Unlike traditional filters made from paper or polymer materials, metal filters can withstand extreme conditions, making them suitable for applications involving hot gases or aggressive chemicals. For instance, in the oil and gas industry, where processes often operate under high pressure and temperature, metal filter elements ensure reliable filtration without the risk of degradation.

Moreover, metal filters offer exceptional mechanical strength, which is essential in industrial environments where filters are subject to physical stress. This durability translates into a longer service life, reducing the need for frequent replacements. Consequently, companies can save significantly on maintenance costs and downtime associated with changing filters.

Another important factor is the reusability of metal filter elements

. Many metal filters can be cleaned and restored to their original performance level, allowing for a sustainable practice that minimizes waste. This characteristic is particularly beneficial for businesses looking to enhance their environmental credentials while maintaining operational efficiency.metal filter element

In addition to their mechanical properties, metal filter elements provide superior filtration performance. They are available in various pore sizes, allowing industries to select filters tailored to their specific needs. This customization helps in achieving optimal filtration, whether it involves removing particulates from liquids in pharmaceutical production or filtering out impurities in food processing.

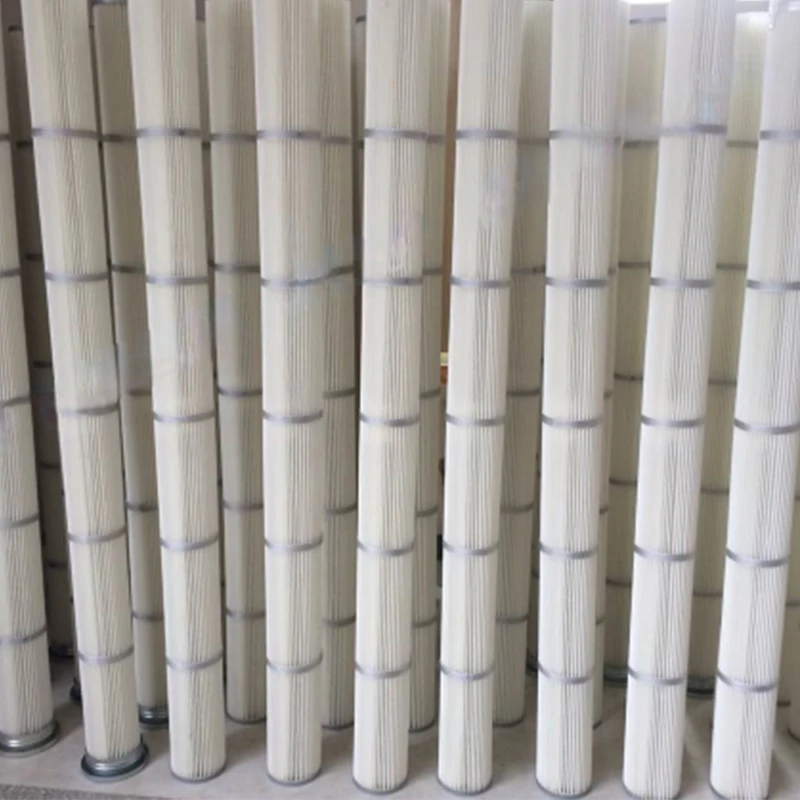

Furthermore, advancements in manufacturing technologies have led to innovative designs that enhance the performance of metal filters. Features like pleated structures increase the surface area, improving flow rates and filtration efficiency. Technologies such as sintering or laser-cutting have also enabled the production of intricate filter geometries that cater to challenging applications.

The integration of metal filter elements in industrial systems also contributes to process safety. By effectively removing contaminants, they reduce the risk of equipment damage and product contamination, thereby enhancing overall operational reliability. In highly regulated industries, maintaining strict quality control is essential, and metal filters play a pivotal role in meeting these standards.

In conclusion, metal filter elements represent a critical component across various industries, providing robust solutions for filtration challenges. Their ability to withstand harsh conditions, combined with superior performance and reusability, positions them as an essential choice for businesses aiming to enhance efficiency and ensure product quality. As industries continue to evolve, the role of metal filter elements will undoubtedly become more significant, driving innovation and sustainability in filtration technologies.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: