ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Ιαν . 30, 2025 03:30 Back to list

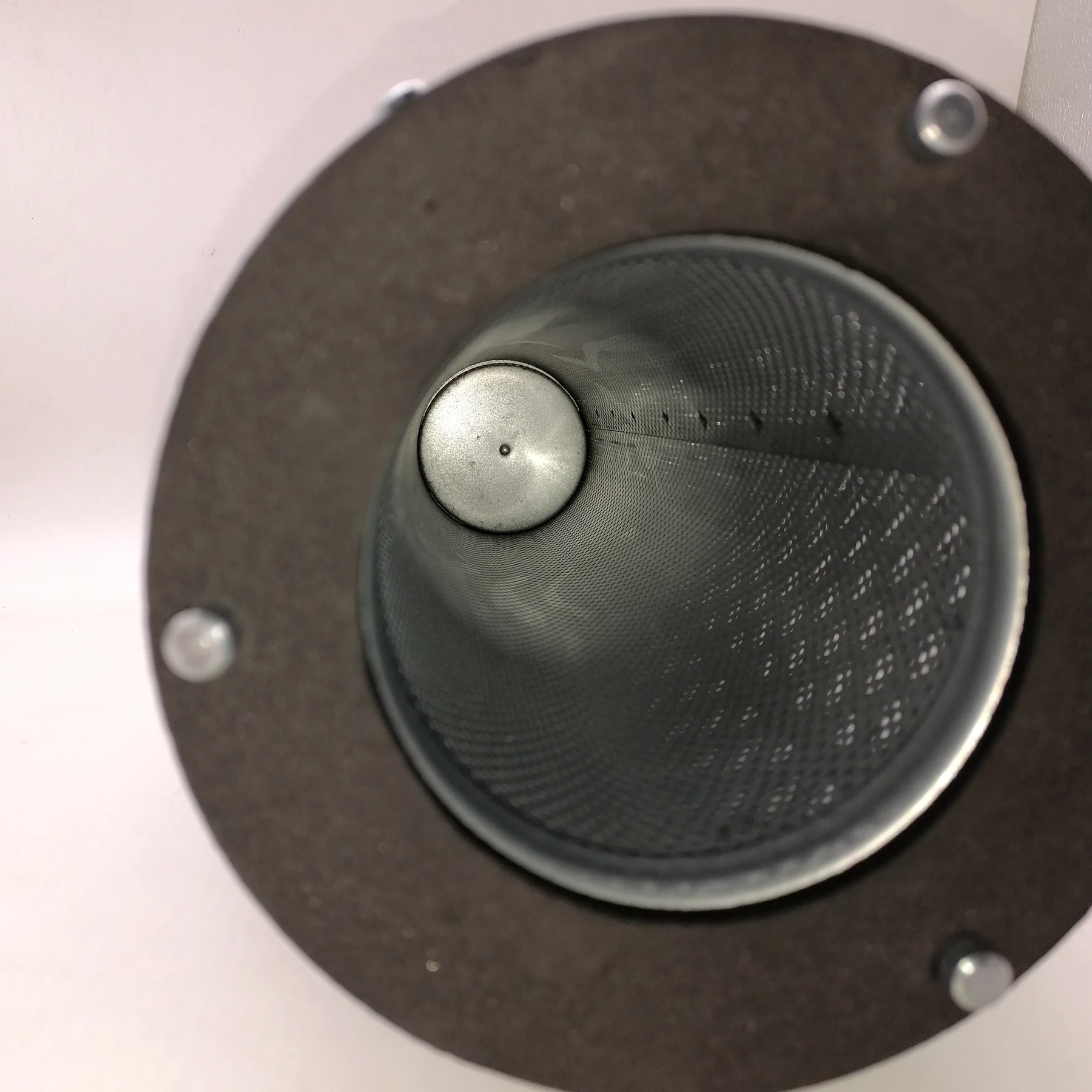

metal filter element

The use of metal filter elements in various industries underscores their significance in ensuring operational efficiency and product purity. Designed for durability and functionality, these filters serve as crucial components in sectors ranging from agriculture to automotive and beyond.

In terms of expertise, installing and maintaining metal filter elements requires specialized knowledge and skills. Professionals trained in the use of these components can provide invaluable insights into optimizing filter performance and longevity. Regular maintenance, including cleaning and inspection, is essential to extend the service life of metal filters. Techniques such as backwashing with water or using cleaning chemicals can remove accumulated debris, ensuring that the filter element continues to perform at its best. Furthermore, partnering with a reputable supplier who understands the nuances of metal filter technology can significantly enhance system reliability and performance. Authoritativeness in the realm of metal filter elements is derived from the continuous research and development carried out by manufacturers and industry experts. Innovations such as multi-layered metal filters and the integration of nanotechnology have propelled these filters into new levels of efficiency and functionality. Industry bodies and standards organizations often validate the efficacy of these advancements, further underscoring their importance and establishing trust in their capabilities. Trustworthiness in the context of metal filter elements is closely linked to their ability to consistently deliver on performance metrics. Users often report high levels of satisfaction due to the reliability and durability offered by metal filters. Additionally, many suppliers provide comprehensive warranties and customer support services that further build user confidence. This assurance of quality and support is critical, especially when filters are employed in mission-critical applications where failure is not an option. To summarize, the evolving landscape of industrial filtration continually demands robust, adaptive solutions. Metal filter elements, with their proven track record of durability, efficiency, and versatility, stand out as a vital component in meeting these needs. Their application across a wide array of industries not only enhances operational efficiency but also ensures compliance and quality assurance. By leveraging the expertise and innovation within the industry, businesses can harness the full potential of metal filter elements to drive success and maintain a competitive edge in their respective fields.

In terms of expertise, installing and maintaining metal filter elements requires specialized knowledge and skills. Professionals trained in the use of these components can provide invaluable insights into optimizing filter performance and longevity. Regular maintenance, including cleaning and inspection, is essential to extend the service life of metal filters. Techniques such as backwashing with water or using cleaning chemicals can remove accumulated debris, ensuring that the filter element continues to perform at its best. Furthermore, partnering with a reputable supplier who understands the nuances of metal filter technology can significantly enhance system reliability and performance. Authoritativeness in the realm of metal filter elements is derived from the continuous research and development carried out by manufacturers and industry experts. Innovations such as multi-layered metal filters and the integration of nanotechnology have propelled these filters into new levels of efficiency and functionality. Industry bodies and standards organizations often validate the efficacy of these advancements, further underscoring their importance and establishing trust in their capabilities. Trustworthiness in the context of metal filter elements is closely linked to their ability to consistently deliver on performance metrics. Users often report high levels of satisfaction due to the reliability and durability offered by metal filters. Additionally, many suppliers provide comprehensive warranties and customer support services that further build user confidence. This assurance of quality and support is critical, especially when filters are employed in mission-critical applications where failure is not an option. To summarize, the evolving landscape of industrial filtration continually demands robust, adaptive solutions. Metal filter elements, with their proven track record of durability, efficiency, and versatility, stand out as a vital component in meeting these needs. Their application across a wide array of industries not only enhances operational efficiency but also ensures compliance and quality assurance. By leveraging the expertise and innovation within the industry, businesses can harness the full potential of metal filter elements to drive success and maintain a competitive edge in their respective fields.

Next:

Latest news

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: