Tel:

+8615930870079

Tel:

+8615930870079

Δεκ . 28, 2024 12:50 Back to list

metal filter element

Understanding Metal Filter Elements Applications and Benefits

In various industrial processes, filtration is a critical step to ensure the purity and quality of materials and fluids. One of the most effective solutions for filtration needs is the metal filter element. These components have gained prominence due to their durability, efficiency, and versatility. This article delves into the characteristics, applications, and benefits of metal filter elements.

What Are Metal Filter Elements?

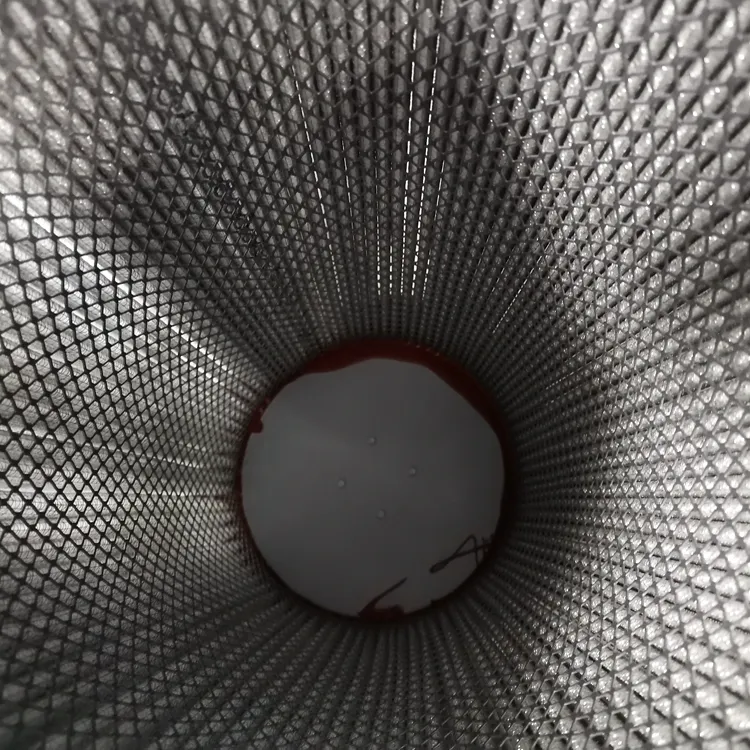

Metal filter elements are filtration devices made of metal, designed to separate solid particulates from fluids or gases. They’re created using different metals, including stainless steel, bronze, and aluminum, which can withstand high temperatures and pressures. Their construction typically involves woven or sintered metal mesh, perforated sheets, or rigid structures. The choice of materials and designs ensures that metal filter elements can effectively filter out contaminants in various environments.

Key Characteristics

1. Durability and Longevity Metal filter elements are renowned for their robustness. Unlike plastic or paper filters, metal filters can endure harsh conditions, including high temperatures, corrosive environments, and high flow rates. This longevity translates into lower replacement costs and reduced waste.

2. Reusability One of the standout features of metal filters is their reusability. They can often be cleaned and maintained, allowing for multiple uses over their lifespan. This not only saves money but also minimizes the environmental impact associated with disposable filters.

3. High Filtration Efficiency Metal filter elements offer excellent filtration precision. Their design allows for the capture of fine particles, ensuring that the output meets strict quality standards. The fine mesh or porous structures used in metal filters can effectively filter out contaminants measured in microns.

4. Versatile Application Metal filter elements can be customized for specific applications, making them suitable for various industries, including automotive, pharmaceutical, food processing, and petrochemical sectors. They can handle different types of fluids and gases, which enhances their applicability.

Applications of Metal Filter Elements

1. Industrial Filtration In manufacturing processes, metal filter elements are used to maintain fluid purity by removing particulates from oils, coolants, and hydraulic fluids. This helps in extending the life of machinery and improving operational efficiency.

metal filter element

2. Food and Beverage Industry Metal filters are critical in applications involving food and beverage production. They are used to eliminate unwanted solids from liquid ingredients, ensuring product quality and safety. Their ability to withstand high temperatures also makes them ideal for sterilization processes.

3. Petrochemical Industry The petrochemical sector relies heavily on metal filter elements to separate contaminants from crude oil and other derived products. Their durability against aggressive chemicals is vital in maintaining equipment performance and safety.

4. Pharmaceutical Applications In the pharmaceutical industry, precision and cleanliness are paramount. Metal filters ensure that the manufacturing processes remain free of contaminants, contributing to compliance with stringent regulatory requirements.

Benefits of Using Metal Filter Elements

1. Cost-Effectiveness Although the initial investment may be higher than traditional filters, the longevity, reusability, and reduced downtime associated with metal filters lead to significant cost savings in the long term.

2. Environmental Sustainability The reusability of metal filter elements means less waste compared to disposable options. In an era where sustainability is a priority, the use of durable and recyclable materials aligns well with environmental practices.

3. Performance Consistency Metal filters provide consistent performance over time, which is crucial for industries that require strict adherence to quality control measures. Their stability under various operating conditions ensures reliable filtration results.

4. Safety In many applications, the failures of filter elements can lead to severe consequences. Metal filter elements, due to their strength and reliability, provide an added layer of safety when handling toxic or hazardous substances.

Conclusion

In conclusion, metal filter elements offer an effective solution for various filtration requirements across multiple industries. With their durability, reusability, and high filtration efficiency, they provide a cost-effective and environmentally friendly alternative to traditional filtration methods. As industries continue to seek ways to enhance efficiency and sustainability, the importance of reliable filtration systems, such as metal filter elements, cannot be overstated. Their role in safeguarding product quality and operational integrity makes them an indispensable component of modern industrial processes.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: