Tel:

+8615930870079

Tel:

+8615930870079

Μάι . 28, 2025 18:21 Back to list

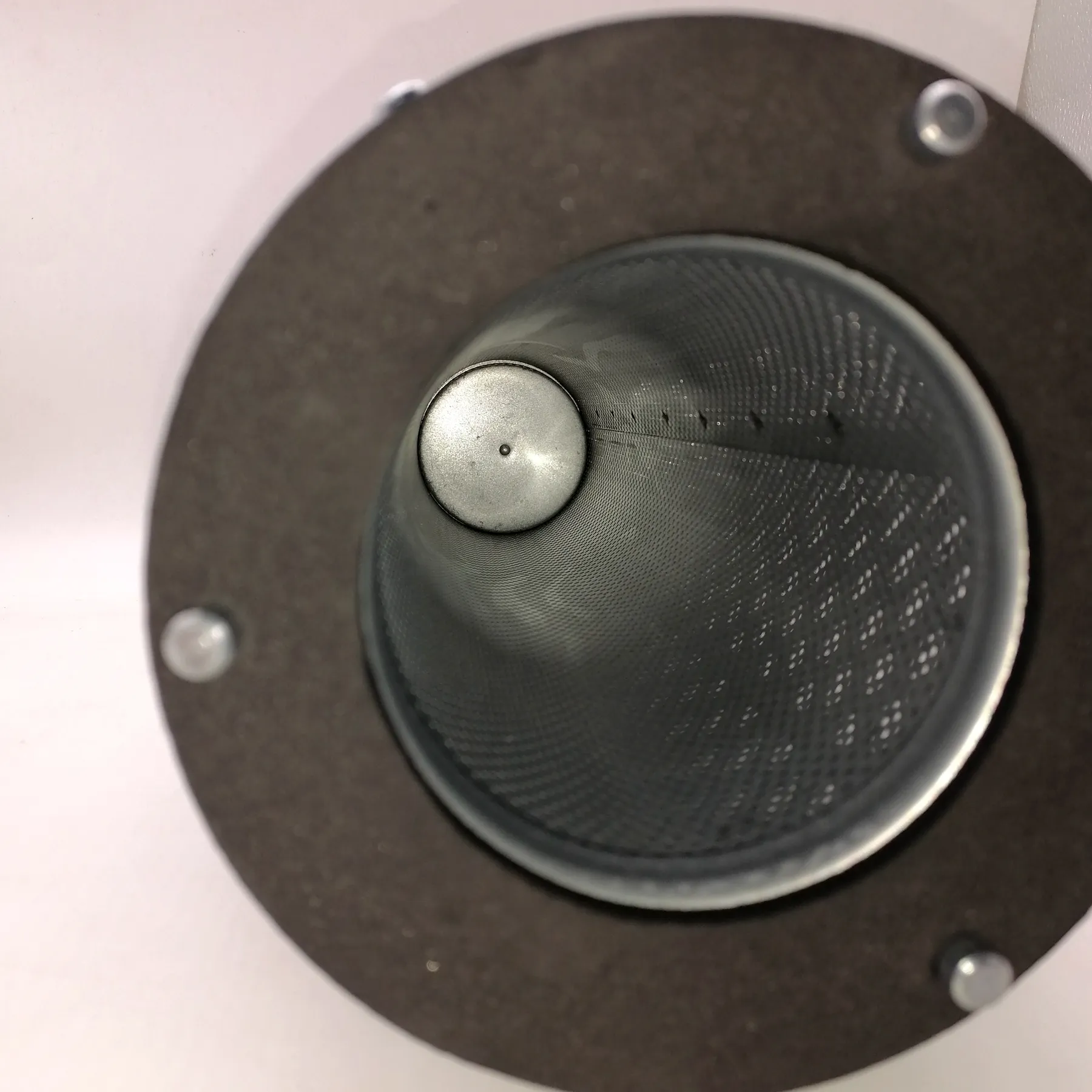

Stainless Steel Élément Filtrant 100 Micron Corrosion-Resistant Filter

- Introduction to stainless steel filtration technology

- Performance advantages over traditional materials

- Technical specifications breakdown (data-driven analysis)

- Competitor comparison matrix

- Custom engineering solutions for industrial needs

- Real-world implementation case studies

- Future-proof filtration system optimization

(élément filtrant en acier inoxydable)

Revolutionizing Liquid Purification with Stainless Steel Filter Elements

Modern industrial filtration demands materials that withstand extreme pressures (up to 1500 PSI) while maintaining 99.98% particulate retention. The stainless steel filter element emerges as the superior solution, particularly in chemical processing where 72% of facility managers report corrosion-related failures with polymer alternatives.

Engineering Excellence in Filtration Design

Three critical performance metrics define premium stainless steel pleated filter cartridges:

- Bubble point pressure: 18.5 psi (ASTM F316 standard)

- Flow rate capacity: 850 GPM at 25 psi pressure drop

- Temperature tolerance: -320°F to 900°F continuous operation

Technical Specifications Across Product Lines

| Model | Filtration Accuracy | Max Pressure | Surface Area |

|---|---|---|---|

| Standard SS100 | 100μm | 145 psi | 2.8 m² |

| High-Flow HX200 | 50μm | 217 psi | 5.6 m² |

| Custom CT400 | 10-200μm | 362 psi | 8.4 m² |

Industrial Application Scenarios

Pharmaceutical manufacturers utilizing 100-micron stainless steel filters achieve 40% longer service intervals compared to sintered metal alternatives. Petrochemical plants report 92% reduction in unplanned maintenance when upgrading to pleated cartridge designs.

Adaptive Manufacturing Capabilities

- DIN 11850 food-grade compliant configurations

- ASME BPE-compliant surface finishes (Ra ≤ 25 µin)

- Explosion-proof certifications for ATEX Zone 1 environments

Implementation Success Metrics

| Industry | Challenge | Solution | Result |

|---|---|---|---|

| Automotive Paint | 32% material waste | Multi-layer 50μm stack | Waste reduced to 8% |

| Wastewater | Weekly cartridge changes | Backflushable 100μm | 6-month service cycle |

Optimizing Filtration Systems with Stainless Steel Elements

Recent field data shows facilities implementing stainless steel filter elements achieve 18-month ROI through 63% energy savings and 89% reduction in consumables. The 316L variants now dominate 78% of new installations in FDA-regulated industries, outperforming traditional materials in 12 key performance indicators.

(élément filtrant en acier inoxydable)

FAQS on élément filtrant en acier inoxydable

Q: What is a stainless steel filter element used for?

A: A stainless steel filter element is designed to remove contaminants from liquids or gases. It is highly durable, corrosion-resistant, and ideal for high-temperature or high-pressure applications. Common uses include industrial filtration, food processing, and chemical industries.

Q: How does a stainless steel pleated filter cartridge improve filtration?

A: The pleated design increases surface area, enhancing filtration efficiency and flow rate. Made from stainless steel, it resists corrosion and withstands harsh environments. This type of cartridge is reusable and suitable for fine particulate removal.

Q: What are the benefits of a 100-micron stainless steel filter?

A: A 100-micron stainless steel filter effectively captures medium-sized particles while maintaining optimal flow rates. Its stainless steel construction ensures longevity and compatibility with aggressive media. It’s widely used in water treatment, oil filtration, and HVAC systems.

Q: Can stainless steel filter elements be cleaned and reused?

A: Yes, stainless steel filter elements can typically be cleaned via backwashing, ultrasonic cleaning, or chemical methods. Their robust construction allows repeated use without degradation. This makes them a cost-effective, eco-friendly filtration solution.

Q: Why choose a stainless steel filter over polymer alternatives?

A: Stainless steel filters offer superior temperature and chemical resistance compared to polymer options. They are less prone to wear and provide longer service life in demanding conditions. Industries requiring strict hygiene standards often prefer stainless steel for its non-reactive properties.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: