Tel:

+8618931101301

Tel:

+8618931101301

Αυγ . 09, 2024 01:20 Back to list

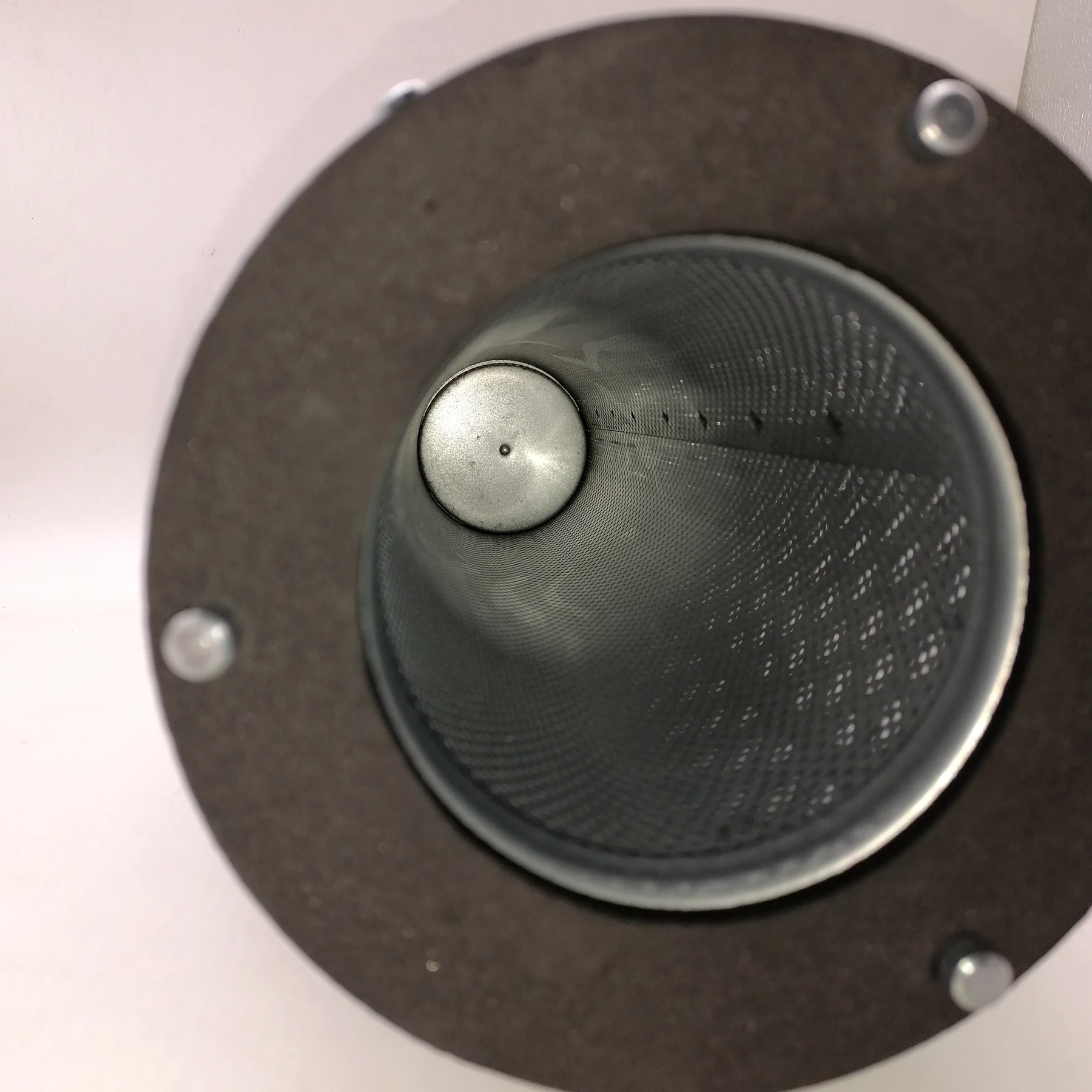

High Efficiency Sintered Metal Filter Cartridge for Industrial Applications and Fluid Purification Solutions

Sintered Metal Filter Cartridges An Overview

Sintered metal filter cartridges are becoming increasingly popular in various industrial applications due to their superior durability, efficiency, and versatility. These filters are made from porous metal materials, typically stainless steel or bronze, which have been processed through a sintering process. This involves heating the metal powders to a point where they fuse together without melting, creating a solid structure with controlled porosity.

Structure and Manufacturing

The manufacturing of sintered metal filter cartridges involves several key processes. Initially, metal powders are compacted into the desired form, after which they undergo sintering. The temperature and duration of the sintering process are meticulously controlled to ensure the formation of a porous structure that allows specific flow rates while removing contaminants effectively. The resulting filter media exhibits unique properties, such as high strength and resistance to extreme temperatures and pressures, making it suitable for demanding environments.

Advantages of Sintered Metal Filters

1. Durability One of the primary advantages of sintered metal filter cartridges is their remarkable durability. Unlike traditional filtration materials that can degrade over time, sintered metal filters can withstand harsh conditions, including extreme temperatures and corrosive environments. This longevity translates to lower replacement costs and reduced downtime for maintenance.

2. Reusability Sintered metal filters can be cleaned and reused multiple times. Their robust design allows for various cleaning methods, including backwashing, ultrasonic cleaning, and chemical cleaning. This reusability not only enhances cost-effectiveness but also contributes to sustainable industrial practices by reducing waste.

sintered metal filter cartridge

3. Precision Filtration These filter cartridges can be engineered to achieve specific filtration ratings, making them effective for a wide range of applications. They can filter out particles down to a few microns in size, ensuring high-quality removal of impurities, which is crucial in industries like pharmaceuticals, food and beverage, and oil and gas.

4. Versatility Sintered metal filters are incredibly versatile and can be designed to suit various applications, including liquid and gas filtration. They can be used in process filters, hydraulic filters, and more, adapting seamlessly to the unique needs of different industries.

5. Temperature and Chemical Resistance Sintered metal filters can handle extreme temperatures and are resistant to a variety of chemicals, which is crucial in applications where traditional filters may fail. This makes them suitable for environments such as chemical processing, where exposure to aggressive substances is common.

Applications

Sintered metal filter cartridges find applications across multiple industries. In the petrochemical sector, they play a vital role in the filtration of crude oil and other fossil fuels, ensuring the removal of sediments and contaminants. In the food and beverage industry, these filters are essential for maintaining product purity and safety by filtering out unwanted particles during production processes. Additionally, in pharmaceuticals, they ensure compliance with stringent hygiene standards by preventing contamination in drug production.

Conclusion

In conclusion, sintered metal filter cartridges represent a significant advancement in filtration technology. Their durability, reusability, and precision filtration capabilities make them an optimal choice for industries that require reliable and efficient filtration solutions. As industries continuously seek to optimize processes and enhance product quality, the adoption of sintered metal filters is likely to grow, leading to more innovations and improvements in filtration technology. With their numerous advantages and versatile applications, sintered metal filter cartridges are set to become a standard in effective filtration solutions for years to come.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: