Tel:

+8615930870079

Tel:

+8615930870079

Δεκ . 20, 2024 06:12 Back to list

Improving Efficiency of Gas Turbine Inlet Filters for Optimal Performance

Gas Turbine Inlet Filters Ensuring Operational Efficiency and Longevity

Gas turbines are integral components of modern energy production and aeronautics, providing a reliable and efficient means of generating power. However, their performance and longevity can be significantly impacted by the quality of the air they intake. This is where gas turbine inlet filters come into play. These filters serve a crucial role in safeguarding the turbine from contaminants that could compromise its efficiency and performance. In this article, we will delve into the importance of gas turbine inlet filters, the types available, and the best practices for maintaining them.

Importance of Gas Turbine Inlet Filters

Gas turbines operate on the principle of taking in air, compressing it, mixing it with fuel, and igniting the mixture to produce energy. The air used in this process must be as clean as possible, as any particles—be it dust, dirt, or other pollutants—can lead to erosion, corrosion, and fouling within the turbine. Contaminants can cause a decrease in combustion efficiency, increased maintenance costs, and even unplanned downtime.

Moreover, the air entering the turbine can carry moisture and other corrosive elements. Therefore, effective filtration is not just about removing solids; it’s also important to minimize the risk of chemical damage. A well-maintained inlet filter can improve the overall operational efficiency of a gas turbine, leading to longer operational life and lower fuel consumption.

Types of Gas Turbine Inlet Filters

There are several types of inlet filters employed in gas turbine applications, each designed to capture different sizes and types of particles.

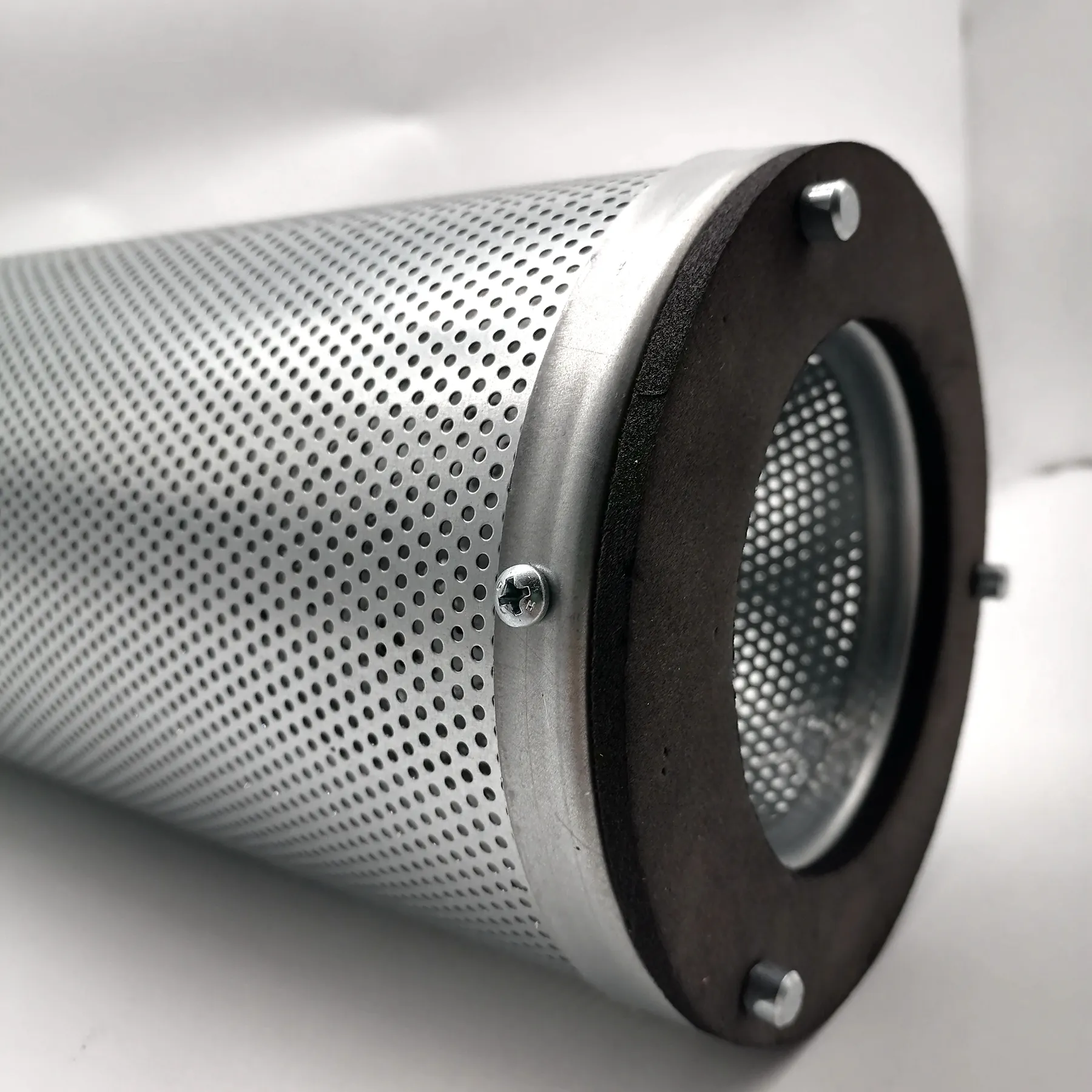

1. Mesh Filters These are typically used for larger particles and can handle coarse dust. Mesh filters are washable and have a long life, making them an economical choice for certain applications.

2. Pleated Filters These filters have a larger surface area compared to traditional flat filters, allowing them to trap more particles without restricting airflow. They are efficient at removing particulate matter and can provide excellent filtration over a longer duration.

3. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are capable of capturing a significant percentage of particles as small as 0.3 microns. In environments with stringent air quality demands, HEPA filters are invaluable as they can help maintain turbine integrity by filtering out fine dust and other hazardous particulates.

gas turbine inlet filter

4. Electrostatic Filters These filters use electric charges to attract and trap particles, offering a highly efficient way of cleaning the air. Electrostatic filters can be particularly effective in environments with high levels of fine particulate contamination.

Best Practices for Maintenance

Maintaining gas turbine inlet filters is as crucial as selecting the right type of filter. Regular maintenance ensures that the filters continue to operate effectively and prolongs the life of the turbine.

1. Regular Inspections Conducting routine inspections of the inlet filter system is essential. This can involve visual checks for dirt buildup, physical damage, or other signs of wear. It is also important to monitor pressure drops across the filters, as increased pressure can indicate a blockage.

2. Cleaning and Replacement Depending on the type of filter used, cleaning protocols should be established. For washable filters, it is vital to follow manufacturer guidelines for cleaning to avoid damaging the filter media. For disposable filters, establishing a replacement schedule based on operational hours or pressure drop measurements is important.

3. Environmental Monitoring Understanding the environment in which the gas turbine operates can aid in filter maintenance. For instance, turbines located in arid or dusty regions will require more frequent filter changes than those in cleaner, more humid environments.

4. Record Keeping Maintaining detailed records of filter inspections, cleanings, and replacements can help in assessing performance trends and anticipating maintenance needs. This data can also be invaluable for optimizing the filtration system based on operational history.

Conclusion

Gas turbine inlet filters play a vital role in maintaining the operational efficiency and longevity of gas turbines. By selecting the appropriate type of filter, adhering to a rigorous maintenance schedule, and keeping a close eye on environmental factors, operators can significantly reduce the risk of performance degradation and costly downtime. Investing in quality inlet filters and their maintenance not only enhances turbine reliability but also contributes to more sustainable energy production practices.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: