Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 11, 2024 08:06 Back to list

gas turbine air intake filter

Gas Turbine Air Intake Filter Importance and Functionality

Gas turbines are a cornerstone of modern energy generation, and their efficiency and reliability hinge upon several critical components. Among these, the air intake filter plays a pivotal role. This article explores the importance of gas turbine air intake filters, their functionality, types, and maintenance considerations, ensuring optimal performance of the gas turbine.

Role of Air Intake Filters in Gas Turbines

Air intake filters are essential for protecting gas turbines from contaminants in the atmosphere. These contaminants can include dust, dirt, pollen, and other particulate matter. When air is drawn into a gas turbine, these impurities can harm key components, leading to decreased efficiency, increased wear, and potential failure.

The primary function of an air intake filter is to clean the incoming air by trapping these impurities, ensuring that only clean air enters the turbine. Clean air is critical for efficient combustion. Impurities can disrupt the combustion process, leading to incomplete burning of fuel, increased emissions, and a drop in overall performance. Therefore, maintaining the integrity of the air intake filter is vital for the operational sustainability of gas turbines.

Types of Air Intake Filters

Air intake filters for gas turbines come in various designs and materials, each with unique advantages and applications

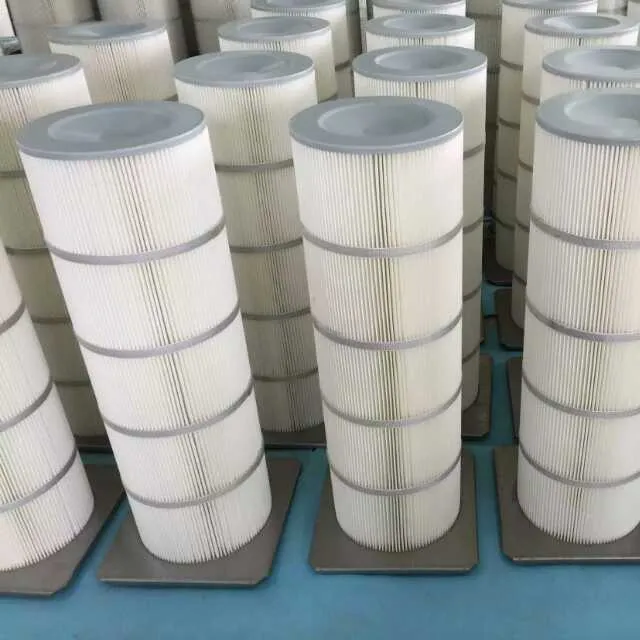

1. Mechanical Filters These are the most common type and include various forms such as bag filters, panel filters, and cylindrical filters. They rely on physical barriers to capture particles as air passes through.

2. Electrostatic Filters These filters use electrostatic charges to attract and capture particulates from the air. They tend to have a higher efficiency rating than mechanical filters and can capture smaller particles.

3. Washable Filters These filters can be cleaned and reused, providing a cost-effective solution for turbine operators. Regular cleaning can ensure continued high performance, although they may require more maintenance than disposable filters.

gas turbine air intake filter

4. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to trap a vast majority of airborne particles. Although more expensive, they provide excellent filtration and are often used in environments where air quality is crucial.

The Maintenance of Air Intake Filters

Proper maintenance of air intake filters is critical to ensure their performance and extend the life of the gas turbine. Generally, maintenance includes regular inspection, cleaning, and replacement of filters. The frequency of these tasks can depend on several factors, including the operating environment, the type of filter used, and the operational hours of the turbine.

1. Inspection Operators should routinely check filters for signs of clogging or damage. A clogged filter restricts airflow, and this can lead to increased pressure drop across the filter, reducing the turbine's efficiency.

2. Cleaning For washable or reusable filters, implementing a regular cleaning schedule is crucial. This can be done using compressed air or water, ensuring that the filter is effectively returning to its optimal performance level.

3. Replacement Disposable filters should be replaced based on the manufacturer’s recommendations or when inspection reveals that they are too dirty to clean effectively.

Conclusion

Gas turbine air intake filters are a vital component in the operation of gas turbines. They serve to protect the turbine from harmful particulates, ensuring that the incoming air is clean and ready for efficient combustion. With various types of filters available, operators must choose the right one based on their specific application and maintain it diligently for optimal performance.

In today's rapidly evolving energy landscape, where efficiency and reliability are paramount, understanding the role of air intake filters can significantly impact the operational longevity and effectiveness of gas turbines. As the demand for cleaner energy sources continues to rise, ensuring the integrity of gas turbine components, including air intake filters, is more crucial than ever in safeguarding against inefficiencies and maximizing output in energy production.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: