Tel:

+8615930870079

Tel:

+8615930870079

Αυγ . 25, 2024 03:37 Back to list

gas turbine air intake filter manufacturers

Gas Turbine Air Intake Filter Manufacturers Ensuring Optimal Performance and Efficiency

In the world of energy production, gas turbines play a crucial role in generating electricity, providing propulsion for aircraft, and powering various industrial processes. One vital component that ensures their efficiency and longevity is the air intake filter. Manufacturers specializing in gas turbine air intake filters not only enhance the performance of these machines but also contribute to sustainable energy practices.

Air intake filters serve to purify the air entering gas turbines, removing contaminants such as dust, dirt, and moisture that could potentially impair performance. Without effective filtration, these pollutants can lead to wear and tear on turbine components, reducing efficiency and increasing maintenance costs. Therefore, the role of air intake filters cannot be overstated.

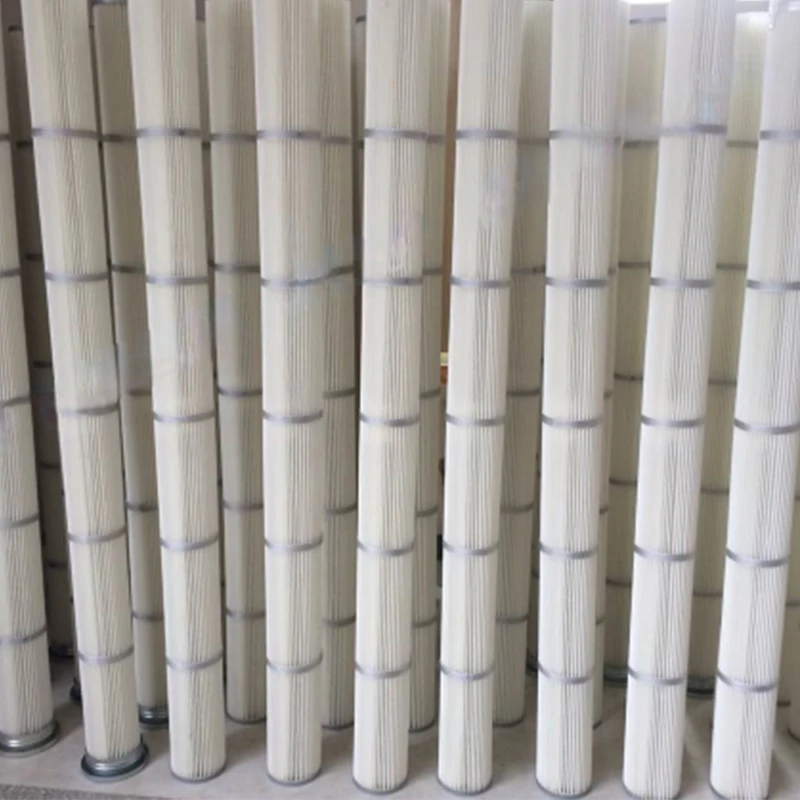

Leading manufacturers focus on designing and producing filters that meet stringent industry standards. These filters come in various designs, including panel filters, bag filters, and cartridge filters, each tailored to specific operational conditions and requirements. The choice of filter depends on various factors such as the environmental conditions of the installation site, the requirements of the gas turbine, and the desired maintenance schedule.

One of the significant advancements in filter technology is the development of high-efficiency particulate air (HEPA) filters. These filters boast high dust-holding capacity and can remove particles as small as 0.3 microns, ensuring that the air entering the turbine is as clean as possible. Innovations in filter media, such as synthetic fibers and nanofiber technology, have also enhanced efficiency and longevity, allowing for longer service intervals and lower operational costs.

gas turbine air intake filter manufacturers

In addition to performance, environmental considerations rank high in the manufacturing process. Many leading manufacturers are committed to sustainability, utilizing recyclable materials in their filter constructions and minimizing waste during production. Furthermore, by improving turbine efficiency, these filters help to reduce emissions and fuel consumption, aligning with global efforts to combat climate change.

Collaboration is another key aspect of the air intake filter manufacturing industry. Manufacturers often work closely with gas turbine producers and end-users to develop customized filtering solutions that meet specific operational needs. This collaboration ensures that the filters not only enhance performance but also fit seamlessly into existing systems.

Moreover, the industry is continually evolving, with manufacturers investing in research and development to explore new materials, designs, and technologies. Smart technology integration is on the rise, with filters equipped with sensors to monitor performance and alert operators when maintenance is due. This predictive maintenance approach reduces downtime and helps maintain the operation of gas turbines at peak performance.

In conclusion, gas turbine air intake filter manufacturers play an essential role in the energy sector, enhancing the efficiency and reliability of gas turbines. As technology advances and environmental concerns grow, these manufacturers remain at the forefront, developing innovative solutions to meet the ever-changing needs of global energy production. By investing in high-quality filtration systems, operators can ensure that their gas turbines operate efficiently, sustainably, and cost-effectively for years to come.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: