Tel:

+8615930870079

Tel:

+8615930870079

Δεκ . 20, 2024 23:53 Back to list

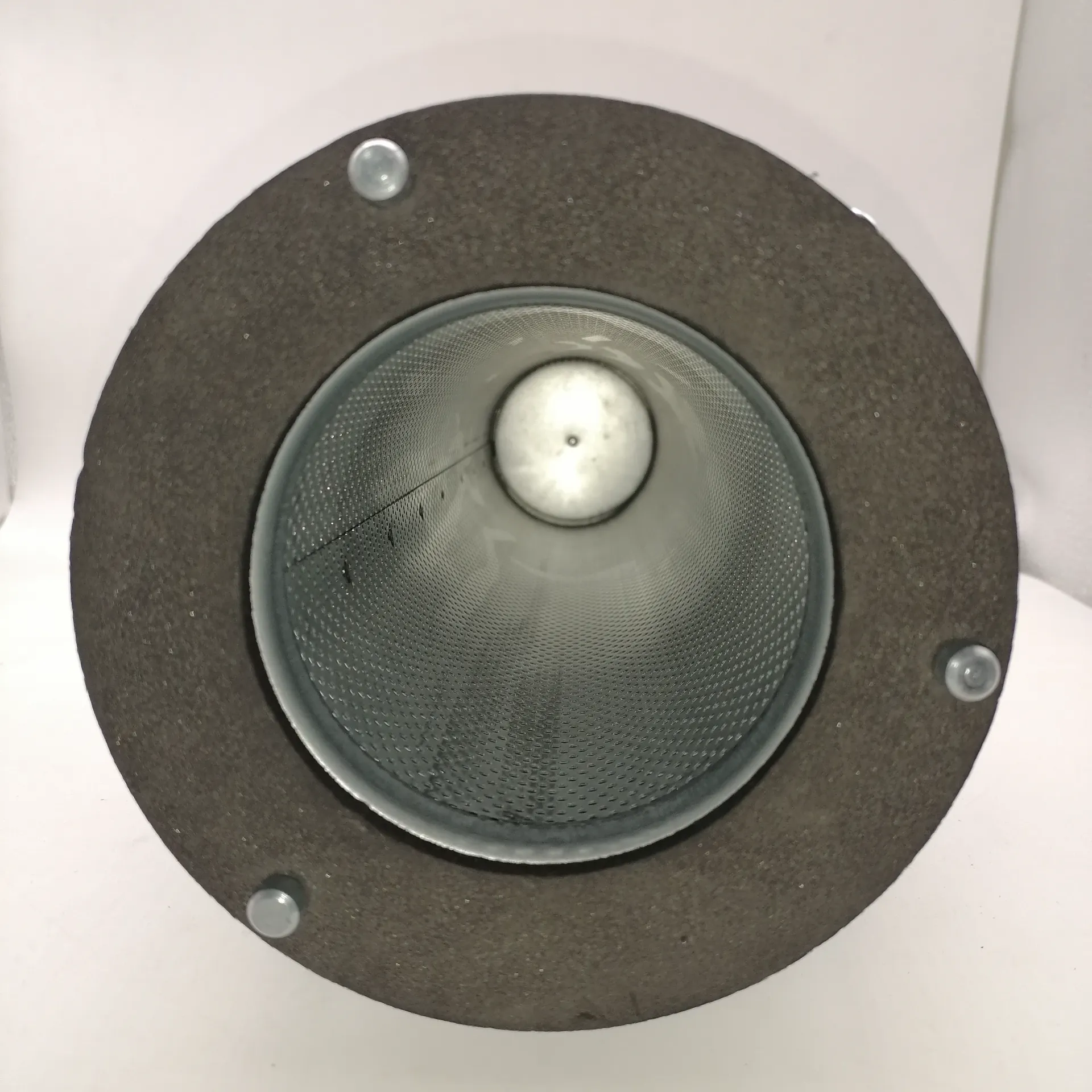

Cartridge Filters for Effective Dust Extraction in Industrial Environments

Understanding Dust Extractor Cartridge Filters Essential Components for Effective Dust Management

In various industries, especially those dealing with woodworking, metalworking, and construction, the management of airborne particulate matter is a critical concern. Dust extractors play a pivotal role in maintaining clean and safe working environments. Among the many components of dust extraction systems, cartridge filters stand out for their efficiency and effectiveness in filtering fine dust particles. This article delves into the significance of dust extractor cartridge filters, their functioning, advantages, and maintenance.

What is a Dust Extractor Cartridge Filter?

A dust extractor cartridge filter is a specialized filtration component designed to capture and contain dust particles generated during industrial processes. Unlike traditional bag filters, cartridge filters utilize a cylindrical shape with a high surface area that allows them to filter finer dust, thereby enhancing the overall efficiency of dust collection systems.

How Do Cartridge Filters Work?

Cartridge filters work based on the principles of mechanical filtration. As air laden with dust particles enters the filter, it is directed through the filter media, which is made from advanced materials such as polyester, polypropylene, or PTFE (polytetrafluoroethylene). The filter media traps dust particles while allowing clean air to pass through. Over time, as dust accumulates, the filter experiences a pressure drop, which can reduce the efficiency of the dust extractor.

To mitigate this, many cartridge filters are equipped with an automatic cleaning system. This system uses compressed air to periodically pulse through the cartridges, dislodging the collected dust, which then falls into a collection bin for disposal. This process ensures that the filter maintains optimal performance and longevity.

Advantages of Cartridge Filters

1. High Filtration Efficiency Cartridge filters can capture particles as small as 0.5 microns, making them especially effective for controlling fine dust, which can be hazardous to health if inhaled.

2. Compact Design The cylindrical shape of cartridge filters allows for a smaller footprint compared to traditional bag filters, making them ideal for facilities with limited space.

4. Easy Maintenance The automated cleaning systems used with cartridge filters simplify maintenance tasks, reducing downtime and labor requirements.

dust extractor cartridge filter

5. Versatility Cartridge filters can be used in a variety of applications, from woodworking shops to metal fabrication facilities, thanks to the range of filter media available.

Applications of Dust Extractor Cartridge Filters

Dust extractor cartridge filters find their use in numerous applications across different industries. In woodworking, they are vital for capturing fine sawdust and particulate matter generated by routers, sanders, and table saws. In metalworking, these filters effectively collect metal shavings and dust from machining processes. Furthermore, in pharmaceutical and food processing sectors, cartridge filters ensure compliance with strict hygiene and safety standards by minimizing cross-contamination and maintaining air quality.

Maintenance and Care

For dust extractor cartridge filters to perform optimally, regular maintenance is essential. Here are some key maintenance tips

1. Regular Inspection Regularly check filters for signs of wear, damage, or excessive dust accumulation.

2. Cleaning Protocol Implement a reliable cleaning protocol. Ensure that the automated cleaning system is functioning correctly and consider manual cleaning if necessary.

3. Replacement Schedule Establish a replacement schedule based on the manufacturer's recommendations and the specific dust load in your facility.

4. Monitoring Airflow Keep an eye on airflow rates; a significant drop might indicate a clogged filter and the need for cleaning or replacement.

5. Professional Servicing Consider periodic professional servicing to assess the overall health of the dust extraction system.

Conclusion

Dust extractor cartridge filters are integral to maintaining a safe and healthy work environment in various industries. Their high filtration efficiency, compact size, and ease of maintenance make them a preferred choice for many businesses. By understanding the importance of these filters and implementing proper maintenance practices, companies can ensure effective dust management, enhancing worker safety and overall operational efficiency. Investing in quality dust extraction systems with cartridge filters not only complies with regulatory standards but also promotes a cleaner, more productive workplace.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: