Tel:

+8615930870079

Tel:

+8615930870079

Δεκ . 07, 2024 14:04 Back to list

dust cartridge

Understanding Dust Cartridge Filters Importance, Functionality, and Applications

In various industrial and commercial environments, controlling dust and particulate matter is crucial for maintaining health and safety standards as well as ensuring operational efficiency. One technology that plays a vital role in this endeavor is the dust cartridge filter. This article explores the importance, functionality, and applications of dust cartridge filters in various sectors.

What are Dust Cartridge Filters?

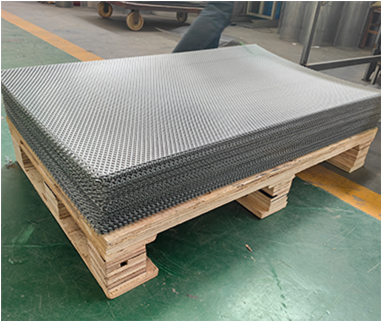

Dust cartridge filters are specialized filtration systems designed to capture and remove airborne dust, particulate matter, and other contaminants from the air. They consist of a cylindrical filter cartridge made of porous materials that allow air to pass through while trapping dust particles. These filters are often utilized in dust collection systems to help maintain a clean and safe working environment.

Importance of Dust Cartridge Filters

Dust cartridge filters are essential for multiple reasons. First and foremost, they help maintain indoor air quality by significantly reducing the concentration of airborne pollutants. This is particularly critical in workplaces where employees may be exposed to harmful dust particles, which can lead to respiratory problems, allergies, and other health issues over time.

Moreover, these filters contribute to the efficiency of industrial operations. By preventing dust accumulation on machinery and equipment, they enhance performance and reduce downtime caused by maintenance. In addition, a clean environment minimizes the risk of explosions and fires often associated with combustible dust in certain industries, such as woodworking and metal fabrication.

How Do Dust Cartridge Filters Work?

dust cartridge

The operational principle of dust cartridge filters is relatively straightforward

. As air containing dust particles flows through the filter cartridge, the contaminants are captured on the surface and in the pores of the filter material. Over time, as more particles accumulate, the filter becomes saturated and requires maintenance.Many modern dust cartridge filter systems are equipped with automated cleaning mechanisms. These systems often employ reverse air or pulse jet cleaning methods to dislodge the accumulated dust from the filter surface. This process not only extends the lifespan of the filter but also maintains optimal airflow and filter efficiency.

Applications of Dust Cartridge Filters

Dust cartridge filters are utilized across various industries, including manufacturing, construction, pharmaceuticals, and food processing. In manufacturing, for instance, they are commonly used in metalworking shops to capture dust from grinding, sanding, and cutting processes. The construction industry also employs these filters to manage dust generated during demolition and renovation activities.

In the pharmaceutical industry, stringent air quality standards necessitate the use of dust cartridge filters to ensure a contaminant-free environment. Similarly, in food processing, these filters help maintain hygiene and product quality by removing flour, sugar, and other fine particles that could compromise safety.

Additionally, dust cartridge filters are beneficial in commercial settings such as warehouses and distribution centers, where dust can accumulate quickly from various operations. By implementing effective dust collection systems, businesses can improve workplace safety and comply with health regulations.

Conclusion

In conclusion, dust cartridge filters play a crucial role in promoting health, safety, and operational efficiency across various industries. Their ability to capture and contain airborne dust and particulate matter not only protects workers’ health but also enhances equipment performance and reduces the risk of accidents. As industries continue to evolve and face new challenges regarding air quality and workplace safety, the importance of advanced dust collection technologies, like dust cartridge filters, will only grow. Investing in these systems is not just a regulatory requirement but a crucial step towards ensuring a sustainable and safe working environment for all.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: