Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 13, 2024 03:18 Back to list

cartridge dust collector filter

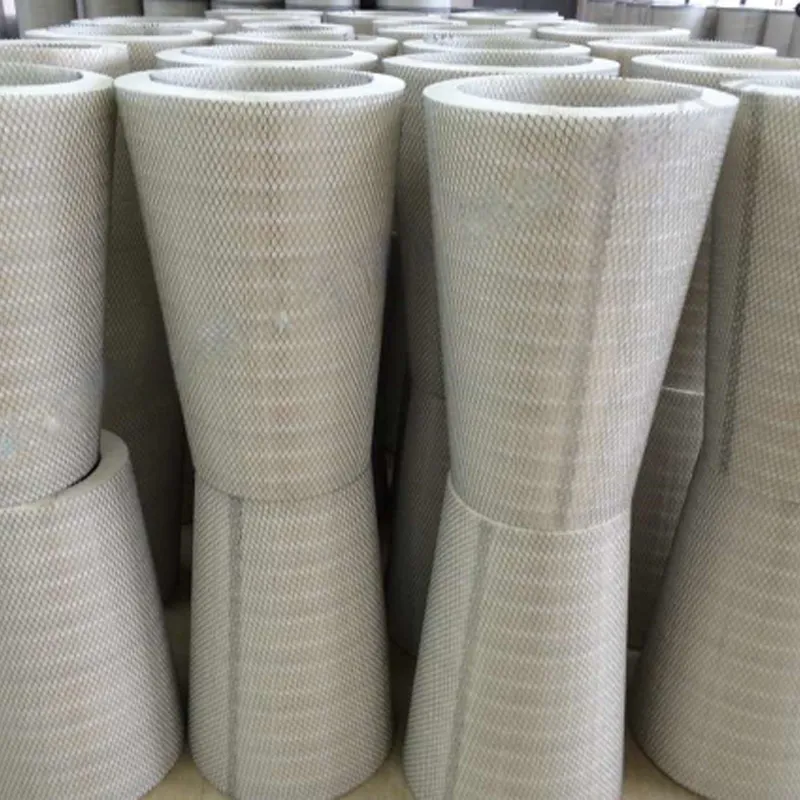

Understanding Cartridge Dust Collector Filters

In industrial and manufacturing environments, the effective management of airborne dust and particulate matter is essential for maintaining both worker health and equipment efficiency. One of the pivotal components in dust collection systems is the cartridge dust collector filter. These filters play a crucial role in capturing fine particles that can otherwise compromise air quality and operational performance. This article explores the functioning, benefits, and maintenance of cartridge dust collector filters.

What is a Cartridge Dust Collector Filter?

A cartridge dust collector filter is a cylindrical filter designed to trap dust, smoke, and other contaminants from the air or gas stream. It is commonly used in various industries, including woodworking, metalworking, pharmaceuticals, and food processing. Unlike traditional bag filters, cartridge filters utilize advanced filtration technology, offering better performance in capturing smaller particles while maintaining relatively low pressure drops.

How does it Work?

The cartridge filter operates by employing a combination of mechanical and electrostatic forces to capture particulates. Air enters the dust collector and passes through the filter media, which is typically made from synthetic materials or treated cellulose. The design of the cartridge allows for a large surface area, enhancing its ability to catch more dust as air flows through it.

The filtration process can be broken down into three primary mechanisms

1. Interception Particles follow the flow of the air and come into contact with the filter media fibers, becoming trapped. 2. Inertia Larger particles, due to their mass, have a tendency to continue on their trajectory and collide with the filter media, where they get captured.

3. Diffusion Fine particles, influenced by Brownian motion, deviate from the airstream and hit the filter fibers, leading to their capture.

These mechanisms work together to ensure that even the smallest dust particles are effectively removed from the air, thus enhancing workplace safety and compliance with environmental regulations.

Benefits of Cartridge Dust Collector Filters

Cartridge dust collector filters offer several advantages over traditional dust collection systems

. Some key benefits includecartridge dust collector filter

- Higher Efficiency Cartridge filters can capture smaller particles compared to standard bag filters, leading to improved air quality and dust control. - Compact Design Their smaller footprint allows for installation in tight spaces, making them ideal for facilities with limited room.

- Reduced Maintenance Cartridge filters often have a self-cleaning feature, which minimizes the need for manual cleaning and service interruptions.

- Cost-Effectiveness The long lifespan and high dust-holding capacity of cartridge filters can result in lower operational costs over time.

- Versatility These filters can be used in a wide range of applications, from woodshops to heavy manufacturing, making them a flexible solution for various industries.

Maintenance and Care

To ensure optimal performance, regular maintenance of cartridge dust collector filters is essential. Key maintenance practices include

1. Regular Inspection Periodically check filters for any signs of wear or damage, and replace them as needed to prevent excessive pressure drops.

2. Cleaning Many cartridge dust collectors are equipped with a pulse jet cleaning system, which uses bursts of compressed air to clear dust from the filters. Regularly engaging this system helps maintain efficiency.

3. Monitoring Performance Keep an eye on pressure drop readings. An increase can indicate that the filters are becoming clogged, necessitating cleaning or replacement.

4. Replacement Schedule Establish a replacement schedule based on the specific conditions and usage of the dust collector to maintain consistent performance.

Conclusion

Cartridge dust collector filters are an integral component of modern dust collection systems, offering efficient and effective solutions for combating airborne particulates. With their superior filtration capabilities, compact design, and ease of maintenance, they provide essential benefits that contribute to enhanced air quality and a safer working environment. By understanding their operation and adhering to proper maintenance practices, industries can ensure that their dust collection systems function optimally, supporting productivity and regulatory compliance.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: