Tel:

+8615930870079

Tel:

+8615930870079

Σεπ . 07, 2024 21:17 Back to list

Cartridge Vacuum Filter | Efficient Filtration Solutions

Understanding Cartridge Vacuum Filters A Comprehensive Overview

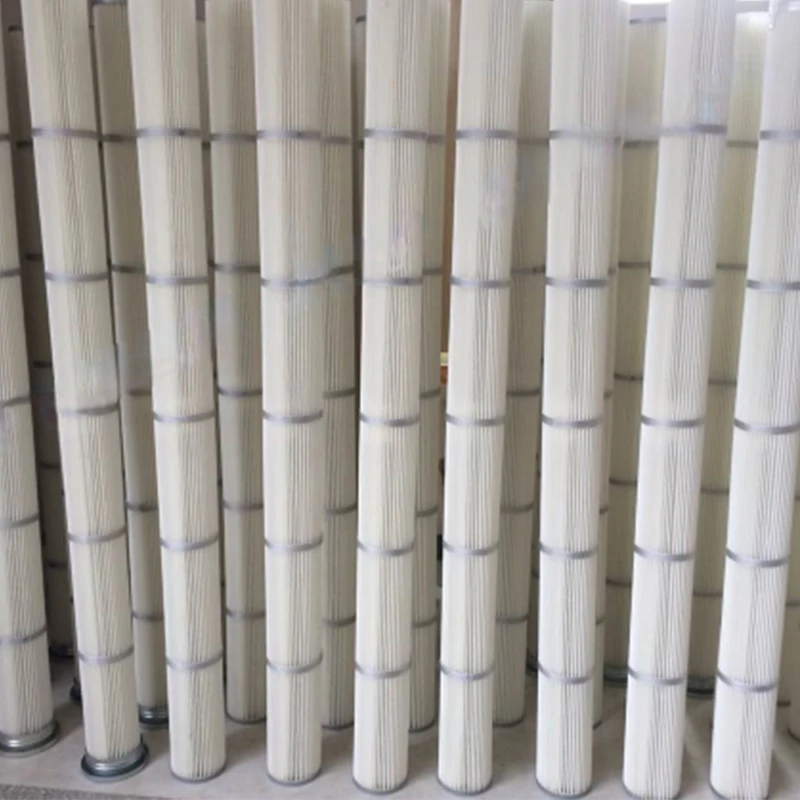

Cartridge vacuum filters have emerged as a pivotal technology in various industries for efficient and effective separation processes. These filters are designed to remove solid particles from liquids or gases, making them an essential component in wastewater treatment, food processing, chemical manufacturing, and many other applications. The main advantage of cartridge vacuum filters lies in their ability to provide a high surface area, facilitating better filtration rates and improved cake release compared to traditional filter media.

Structure and Working Principle

The structure of a cartridge vacuum filter typically consists of a cylindrical housing that contains one or more filter cartridges. Each cartridge is engineered from materials such as polyester, polypropylene, or specialized membranes, depending on the application requirements. When a liquid or gas passes through the filter, solid impurities are trapped within the porous media while the clean effluent flows through, creating a vacuum that enhances the filtration process.

The working principle is straightforward a vacuum is created within the filter chamber, which significantly reduces the pressure on the surface of the cartridge. This pressure difference allows for rapid liquid intake while effectively holding back solids. As the filtration proceeds, a layer of cake forms on the filter surface, which can impede flow. However, the design of cartridge vacuum filters facilitates easy cake removal, either through backwashing or automatic cake discharge mechanisms, ensuring minimal downtime and consistent operation.

Advantages of Cartridge Vacuum Filters

1. High Filtration Efficiency The design and material selection of cartridge vacuum filters allow for a high degree of separation, capturing even ultra-fine particles. This feature is particularly beneficial in industries requiring strict quality control, such as pharmaceuticals and food processing.

cartridge vacuum filter

2. Space-Saving Design Unlike traditional filtration systems, cartridge vacuum filters have a compact footprint, making them suitable for facilities with limited space. Their modular design also allows for easy scalability depending on process requirements.

3. Reduced Operational Costs With their high efficiency and ease of maintenance, cartridge vacuum filters help lower overall operational costs. They can minimize the need for extensive cleaning and reduce downtime associated with equipment changes or repairs.

4. Versatile Applications These filters are adaptable to a wide range of applications, from filtering slurries in mineral processing to separating fine particulates in chemical solutions. This versatility makes them an invaluable asset for various industries.

5. Environmental Benefits By effectively treating wastewater and reclaiming valuable resources, cartridge vacuum filters contribute to environmental sustainability. They help industries meet regulatory standards while minimizing environmental footprints.

Conclusion

In summary, cartridge vacuum filters are an essential technology in the realm of filtration, offering numerous benefits across various industries. Their ability to provide high filtration efficiency, coupled with cost-effectiveness and environmental advantages, underlines their importance in modern manufacturing and processing. As industries continue to seek innovative and efficient separation technologies, cartridge vacuum filters will undoubtedly remain at the forefront, driving advancements in filtration efficiency and sustainability. Businesses looking to enhance their filtration processes should consider the integration of cartridge vacuum filter systems into their operations to gain a competitive edge in their respective markets.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: