Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 29, 2024 09:06 Back to list

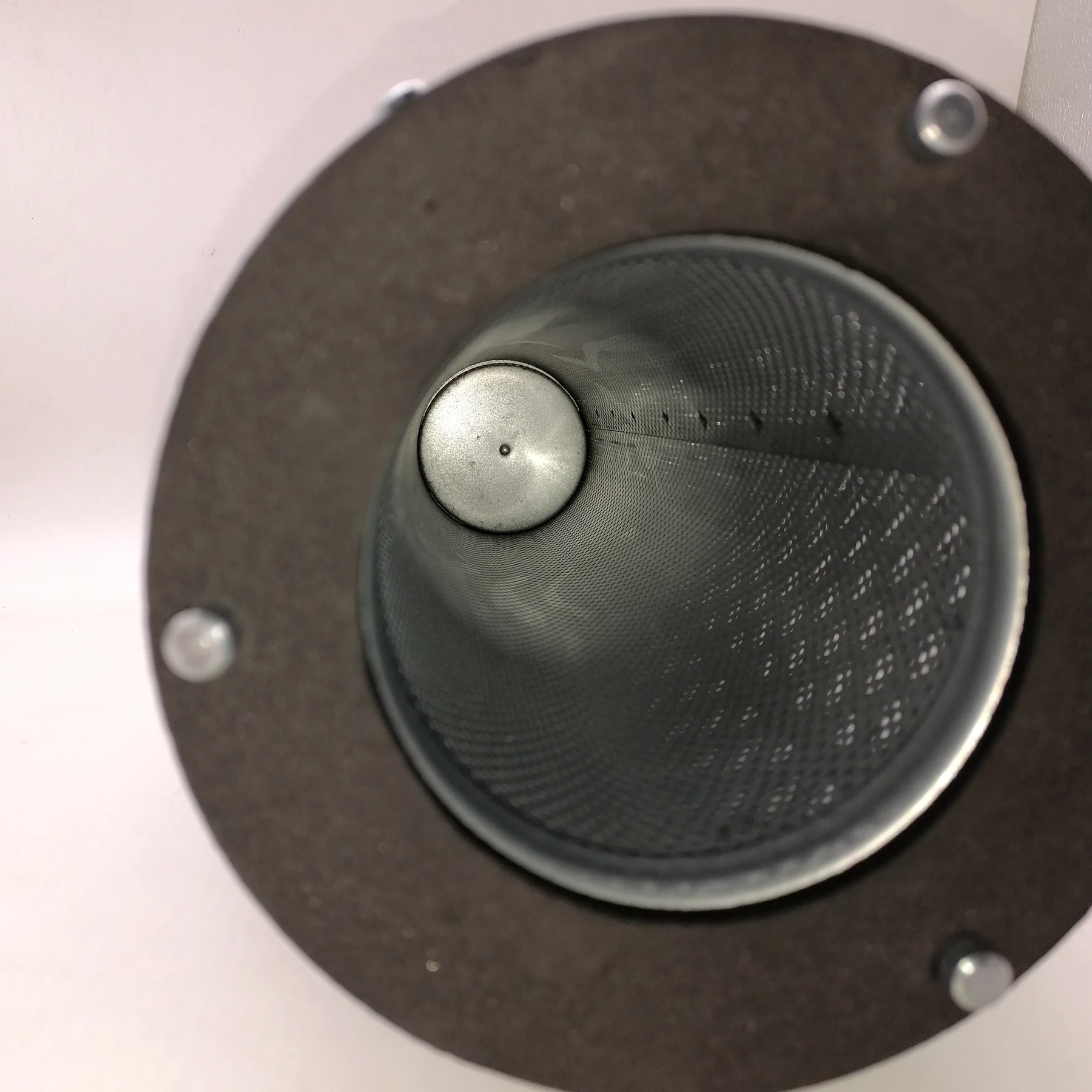

Innovative Antistatic Filter Element for Enhanced Air Quality and Equipment Protection

Understanding Antistatic Filter Elements Importance and Applications

In today's technology-driven world, dust and other pollutants can significantly affect the performance of electronic devices. Antistatic filter elements have emerged as essential components in various industries to prevent damage caused by static electricity. This article will delve into the definition, importance, applications, and advantages of antistatic filter elements.

What is an Antistatic Filter Element?

An antistatic filter element is a specialized component designed to remove airborne particles while simultaneously dissipating static electricity. These filters integrate antistatic materials or coatings, which inhibit the accumulation of static charges. Static electricity can cause dust and particulate matter to cling to surfaces, making it difficult for standard filtration systems to operate effectively. By preventing static charge build-up, antistatic filters ensure that airborne pollutants are effectively captured.

Importance of Antistatic Filter Elements

The importance of antistatic filter elements cannot be overstated, particularly in environments where electronic components and devices are manufactured and handled. Static electricity can cause malfunctions, damage sensitive components, or even result in catastrophic failures. For instance, in cleanroom environments used for semiconductor manufacturing, contamination from dust particles can ruin production processes and lead to significant financial losses.

Antistatic filters protect sensitive equipment by minimizing the introduction of contaminants. They play a critical role in maintaining clean air quality, thus ensuring that manufacturing processes meet stringent industry standards. Moreover, environments that are vulnerable to static buildup—such as data centers, laboratories, and assembly lines—benefit significantly from utilizing these filters.

Applications of Antistatic Filter Elements

Antistatic filter elements find applications in various industries, including

1. Electronics Manufacturing In the production of electronic components, even the slightest dust particles can interfere with operations. Antistatic filters help maintain a clean environment and protect sensitive components from electrostatic discharge (ESD).

2. Pharmaceuticals Contamination in pharmaceutical production can lead to severe consequences. Antistatic filters ensure that airborne particulates are efficiently captured, meeting the cleanliness standards of the industry.

antistatic filter element

3. Food Processing Static electricity can cause dust and other contaminants to adhere to equipment, risking product contamination. Utilizing antistatic filters helps maintain hygienic conditions and ensures compliance with safety regulations.

4. Automotive Industry The automotive sector benefits from clean air filtration, particularly during painting and assembly lines, where static buildup can attract dust and impurities. Antistatic filters contribute to enhancing product quality and consistency.

5. Data Centers In data centers where computers and servers operate continuously, static electricity can cause hardware failures. Antistatic filters help reduce potential risks associated with airflow and dust accumulation.

Advantages of Using Antistatic Filter Elements

The advantages of utilizing antistatic filter elements include

- Enhanced Performance By preventing static charge accumulation, these filters enhance the overall performance of systems by ensuring optimal airflow and minimal contamination.

- Increased Equipment Longevity Reducing static buildup protects sensitive electronic devices, thereby increasing their lifespan and reliability.

- Compliance with Standards Many industries are governed by strict regulations regarding cleanliness and safety. Antistatic filters contribute to compliance with these standards, reducing the risk of fines or closures.

- Cost-Effectiveness Investing in antistatic filtration can mitigate the costs associated with downtime, equipment damage, and remediation from contamination incidents.

Conclusion

Antistatic filter elements are indispensable in maintaining the integrity and functionality of sensitive equipment across various industries. Their ability to mitigate static electricity while effectively filtering airborne debris makes them critical to ensuring compliance with industry standards and preserving product quality. As technology continues to advance, the necessity for effective static control measures, like antistatic filters, will only grow, solidifying their role in modern manufacturing and production environments. Investing in these components is not just a choice but a necessary step toward ensuring safety, quality, and efficiency in an increasingly electronic world.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: