Tel:

+8618931101301

Tel:

+8618931101301

Νοέ . 06, 2024 04:43 Back to list

Static-Free Filtration Solutions for Enhanced Performance and Protection

Understanding Antistatic Filter Elements Importance and Applications

In today's industrial landscape, where electronic devices are omnipresent, the issues associated with static electricity are becoming increasingly significant. Antistatic filter elements play a crucial role in mitigating these concerns, ensuring safety and efficiency in various applications, including manufacturing, cleanrooms, and electronic assembly lines.

What are Antistatic Filter Elements?

Antistatic filter elements are specialized components designed to reduce or eliminate static charges that can accumulate on surfaces or within environments where electronic devices are sensitive to electrical interference. These filters are crafted from materials that not only trap particulates but also possess conductive properties that allow static charges to dissipate safely.

The primary function of these filters is twofold they protect sensitive electronic equipment from static discharge, and they maintain air quality by filtering out harmful particles and contaminants. Some common applications for antistatic filters include HVAC systems, vacuum cleaners, and in-line filters for various industrial processes.

The Mechanism Behind Antistatic Filters

Antistatic filters typically employ a blend of dielectric and conductive materials. The dielectric materials are responsible for capturing dust, pollen, and other airborne particles, while the conductive components allow any built-up static electricity to dissipate safely into the ground or surrounding environment.

These filters are often treated with antistatic agents or coatings that enhance their ability to prevent static buildup. By integrating these features, antistatic filters can significantly reduce the risk of static electricity-induced damage, which can lead to expensive equipment failures or hazardous situations.

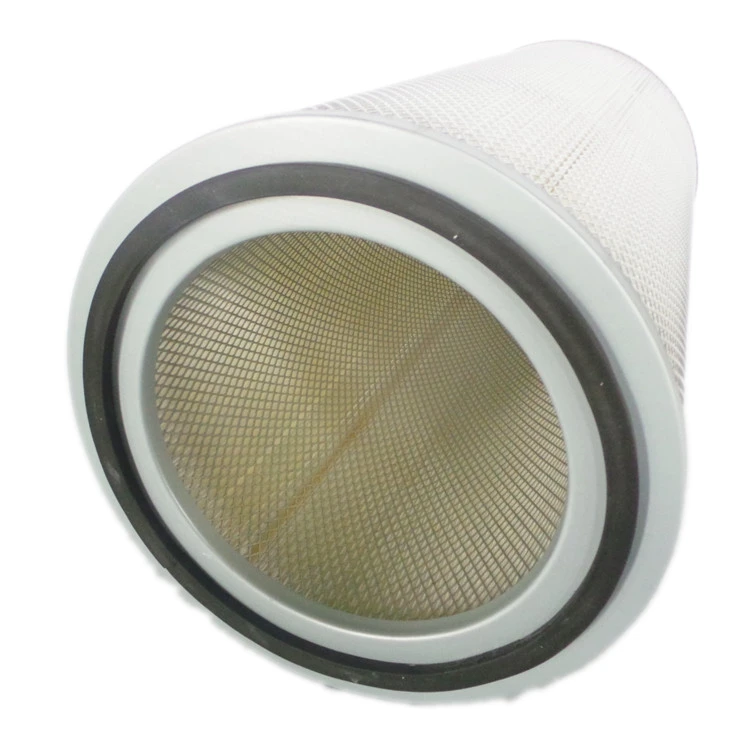

antistatic filter element

Advantages of Using Antistatic Filters

1. Protection of Electronic Equipment The primary benefit of antistatic filters lies in their ability to protect sensitive electronic components from ESD (Electrostatic Discharge). In environments such as cleanrooms or IC manufacturing plants, even a minor static discharge can lead to catastrophic equipment failure and loss of product.

2. Improved Air Quality Antistatic filters are excellent for trapping fine particulates, contributing to better air quality. This improvement is essential in environments that require strict cleanliness standards, such as pharmaceutical production areas, food processing plants, and laboratories.

3. Cost-Effectiveness The initial investment in antistatic filter elements can be recouped quickly through the prevention of equipment damage, reduced downtime, and maintenance costs. By safeguarding electronic devices, businesses can enhance their operational efficiency and productivity.

4. Versatility Antistatic filters can be utilized in various applications, from industrial settings to home appliances. Their adaptability makes them a valuable choice for manufacturers and users alike.

Conclusion

In summary, antistatic filter elements represent a vital component in the management of static electricity within different environments. Their unique design and functionality not only ensure the protection of sensitive electronic devices but also contribute to the overall quality of air in various settings. As industries become increasingly aware of the detrimental effects of static electricity, the adoption of antistatic filters may become more prevalent, underscoring their importance in both industrial and consumer applications. As technology continues to advance, the role of antistatic filters will likely expand, offering even more innovative solutions to static-related challenges.

Investing in quality antistatic filter elements is not merely a precaution but a necessary step towards achieving operational excellence and safety in today’s high-tech world.

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

Email:

Email: