Tel:

+8618931101301

Tel:

+8618931101301

Sep . 23, 2024 13:13 Back to list

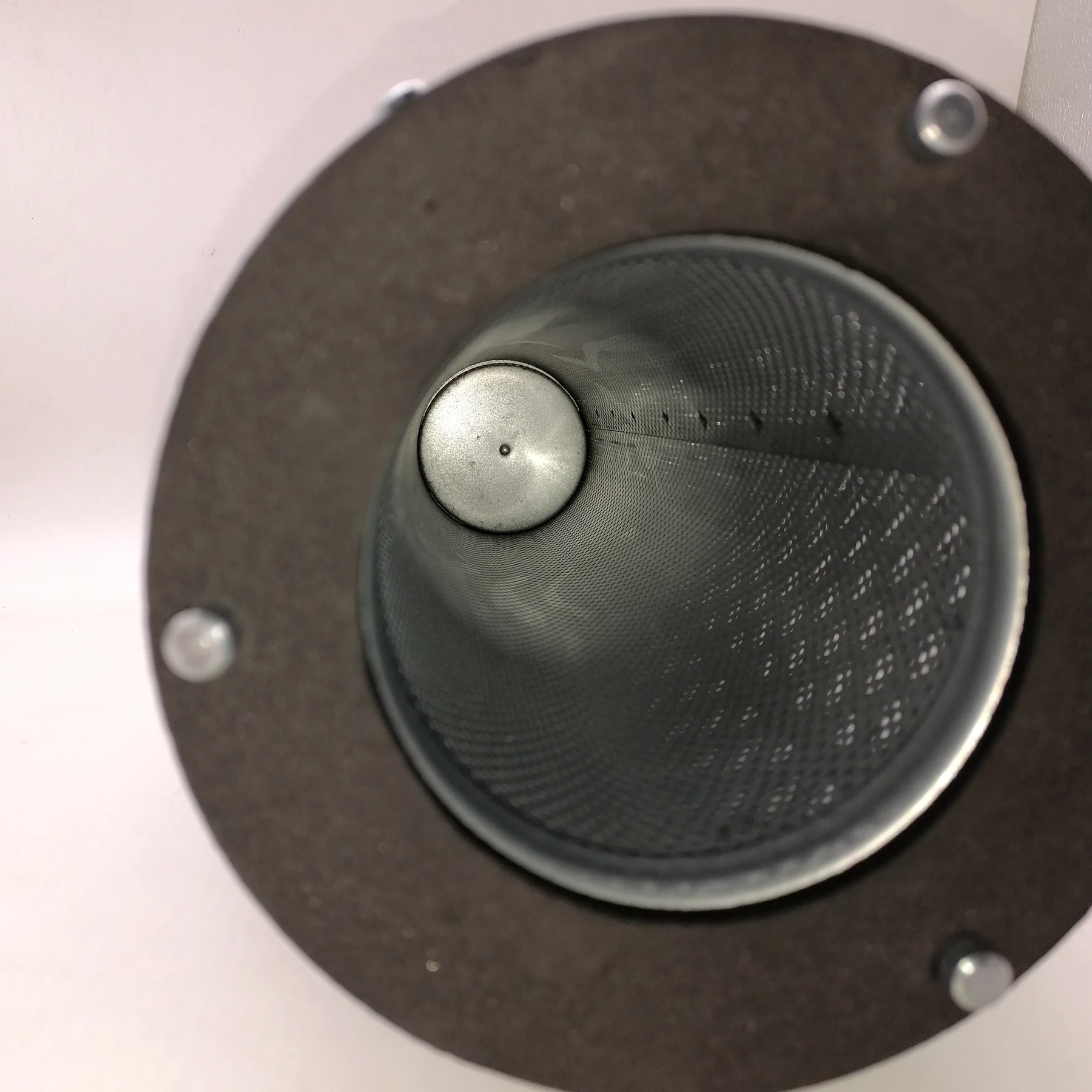

Silo Filter Cartridge Solutions for Efficient Filtration and Dust Control Systems

Understanding Silo Filter Cartridges A Key Component in Industrial Filtration Systems

Silo filter cartridges play a crucial role in the industrial sector, particularly in industries dealing with bulk materials such as food processing, pharmaceuticals, and chemical production. These specialized filters are designed to enhance air quality, protect equipment, and ensure compliance with health and safety regulations. This article aims to explore the significance of silo filter cartridges, their functionality, and the advantages they offer.

What is a Silo Filter Cartridge?

A silo filter cartridge is an essential component of a dust collection system that helps manage particulate emissions generated during the handling, storage, and transportation of bulk materials. These cartridges are typically housed within a dust collector, which captures dust particles through a series of filtration mechanisms. The cartridges function by allowing clean air to pass through while trapping harmful dust and particles, thereby maintaining a safe working environment and protecting machinery.

How Do Silo Filter Cartridges Work?

The operation of silo filter cartridges involves a three-step process filtration, dust cake formation, and cleaning. Initially, when air laden with dust enters the dust collector, it passes through the filter cartridges, which are made from high-efficiency filter media. As the air flows through, dust particles are captured on the surface of the cartridges, while clean air is expelled.

Over time, accumulated dust forms a layer known as a dust cake, which further improves the filtration efficiency. However, excessive dust accumulation can restrict airflow, necessitating a cleaning process. Most dust collectors employ automated cleaning systems, such as reverse pulse jet cleaning, to dislodge dust from the cartridges and restore performance.

Advantages of Using Silo Filter Cartridges

silo filter cartridge

1. Enhanced Air Quality By effectively removing harmful particulate matter from the air, silo filter cartridges contribute to a healthier workplace environment. This helps in minimizing respiratory issues among workers and adheres to environmental regulations.

2. Protection of Equipment Dust accumulation can cause wear and tear on machinery. Silo filter cartridges help protect equipment from dust-related damage, thus prolonging the lifespan of industrial machinery and reducing maintenance costs.

3. Improved Efficiency With their high filtration efficiency, silo filter cartridges ensure optimal airflow and productivity in manufacturing processes. This efficiency translates to cost savings and more streamlined operations.

4. Customization Options Silo filter cartridges can be customized to meet the specific needs of different industries and applications. Various filter media options are available to handle different types of dust and operating conditions, allowing for tailored solutions.

5. Environmentally Friendly Solutions Modern silo filter cartridges are designed with sustainability in mind, often featuring recyclable materials and energy-efficient designs. This commitment to environmental responsibility aids in reducing the overall carbon footprint of industrial operations.

Conclusion

Silo filter cartridges are indispensable components in the realm of industrial filtration systems. They not only promote a safer and cleaner working environment but also protect valuable equipment and enhance operational efficiency. Businesses that prioritize the implementation of effective dust collection strategies can benefit from improved productivity, lower maintenance costs, and compliance with regulatory requirements. In an era where environmental concerns are paramount, investing in high-quality silo filter cartridges is both a responsible and strategic decision for any industrial operation.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: