Tel:

+8615930870079

Tel:

+8615930870079

Dez . 01, 2024 10:19 Back to list

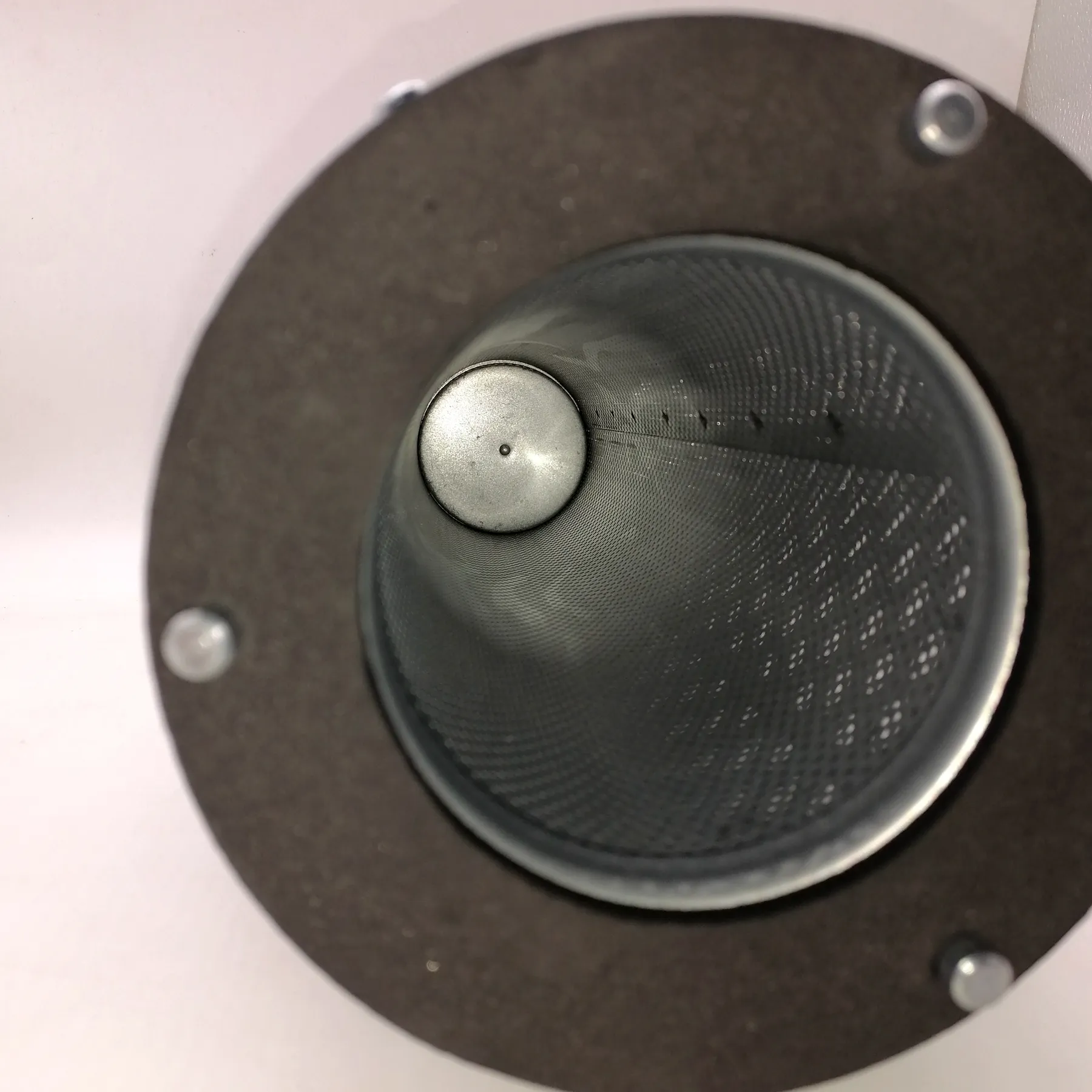

pleated polyester filter cartridge

Understanding Pleated Polyester Filter Cartridges

Filtration is a critical element in various industries, ensuring that processes remain efficient and that products meet quality standards. Among the various types of filters available, pleated polyester filter cartridges have gained significant popularity due to their reliability and effectiveness. This article will explore what pleated polyester filter cartridges are, their benefits, applications, and maintenance considerations.

What Are Pleated Polyester Filter Cartridges?

Pleated polyester filter cartridges are cylindrical filtration devices made from polyester fabric specially designed to capture contaminants from liquids and gases. The pleated design refers to the accordion-like structure of the filter media, which increases the surface area available for filtration. This larger surface area allows for more efficient filtration while maintaining a lower pressure drop compared to non-pleated filters.

Construction and Design

These cartridges typically consist of several components

1. Filter Media The primary component, made from high-quality polyester fibers, is designed to trap particles like dust, dirt, and other impurities. Polyester is chosen for its excellent chemical resistance and durability.

2. Support Core This is often made of polypropylene or stainless steel and provides structural integrity to the cartridge, ensuring it maintains its shape under high pressure.

3. End Caps End caps help seal the cartridge, preventing unfiltered liquid from bypassing the filter. They are usually made from materials that match the filter media, like polypropylene or other durable plastics.

4. Sealing Gaskets These ensure a tight fit within the filter housing, preventing leakage and ensuring that all fluid passes through the filter media.

Benefits of Pleated Polyester Filter Cartridges

Pleated polyester filter cartridges offer several advantages

1. High Filtration Efficiency The pleated design provides a larger surface area, enabling the capture of a higher volume of particles. This design enhances the filter's effectiveness in various applications.

2. Longer Service Life Thanks to the increased surface area, pleated cartridges generally have a longer lifespan compared to standard filters, leading to reduced replacement costs.

pleated polyester filter cartridge

4. Chemical Compatibility Polyester is resistant to many chemicals, making these cartridges suitable for a variety of liquids and gases without degrading.

5. Cost-Effectiveness While the initial investment might be slightly higher than traditional filters, the long-term savings due to increased efficiency and longevity make pleated polyester filter cartridges a cost-effective choice.

Applications

Pleated polyester filter cartridges are versatile and can be utilized in numerous applications, including

- Water Treatment Commonly used in municipal water treatment facilities and swimming pools to remove impurities and enhance water quality. - Industrial Processes Employed in manufacturing processes where clean fluids or gases are essential, such as in pharmaceutical, food and beverage, or chemical industries. - HVAC Systems Used in heating, ventilation, and air conditioning systems to improve indoor air quality by filtering dust, pollen, and other airborne contaminants.

- Oil and Gas Employed to filter out sediments and particulates from oil and gas products, ensuring better product purity and equipment protection.

Maintenance Considerations

While pleated polyester filter cartridges are designed for long service life, proper maintenance is crucial for optimal performance

1. Regular Inspection It is essential to periodically check the filters for blockages or damage. Any visible signs of wear should prompt replacement.

2. Pressure Monitoring Keeping an eye on the pressure differential across the filter can help determine when a cartridge needs to be replaced. A significant increase indicates a clogged filter.

3. Scheduled Replacements Although these filters last longer, developing a maintenance schedule based on flow rates and quality standards is vital.

4. Proper Disposal After use, cartridges should be disposed of according to local regulations, particularly if they have come into contact with hazardous materials.

In conclusion, pleated polyester filter cartridges are valuable components in modern filtration systems, offering efficiency, longevity, and versatility across various applications. Their unique design and material properties make them a preferred choice for industries aiming for excellence in product purity and process efficiency. Investing in high-quality pleated polyester filters not only enhances the filtration process but also contributes to overall operational cost savings.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: