Tel:

+8615930870079

Tel:

+8615930870079

Dez . 09, 2024 23:41 Back to list

Exploring the Benefits of Metal Filter Elements in Various Applications

The Importance of Metal Filter Elements in Industrial Applications

In various industrial sectors, the efficiency and performance of machinery depend significantly on the effectiveness of filtration systems. Among the diverse types of filters available, metal filter elements have gained notable prominence due to their robustness, durability, and superior filtration capabilities. This article delves into the characteristics, advantages, applications, and maintenance of metal filter elements, providing a comprehensive overview of their role in modern industries.

Characteristics of Metal Filter Elements

Metal filter elements are typically made from materials such as stainless steel, alloy steel, and other robust metals. These materials are chosen for their strength and resistance to high temperatures, pressure, and corrosive environments. Metal filters come in various designs, including woven wire mesh, expanded metal, and sintered metal, each offering distinct filtration characteristics. The pore size of these filters can be customized to meet specific requirements, allowing the removal of particulates ranging from large debris to fine particles.

Advantages of Using Metal Filter Elements

1. Durability Metal filter elements can withstand harsh conditions, including extreme temperatures and corrosive chemicals. This durability ensures a longer lifespan compared to traditional non-metallic filters, leading to reduced replacement costs and less frequent downtime in industrial processes.

2. Reusability Unlike many disposable filters, metal filters can often be cleaned and reused. This reusability not only minimizes waste but also makes them a cost-effective solution for industries aiming to reduce operational costs.

3. Versatile Applications Metal filter elements are applicable in numerous sectors, including pharmaceuticals, food and beverage, chemical processing, and oil and gas. Their ability to filter liquids, gases, and powders makes them a versatile choice for various manufacturing processes.

4. High Filtration Efficiency With customizable pore sizes, metal filter elements provide high efficiency in capturing particulate matter without significantly obstructing flow. This efficiency is crucial in maintaining the quality of the final product in sensitive industries.

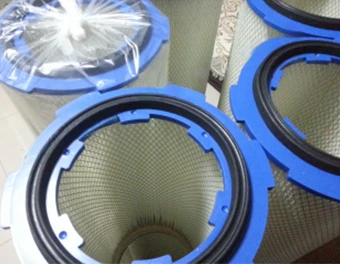

metal filter element

Applications of Metal Filter Elements

The applications of metal filter elements are vast and varied. In the pharmaceutical industry, for instance, they are used in processes requiring sterile conditions, such as in the filtration of injectable medications. In the food and beverage sector, they play a vital role in ensuring product safety and quality by removing contaminants during production.

In the chemical industry, metal filters are essential for separating catalyst materials in chemical reactions. Similarly, in the oil and gas sector, they are used in the filtration of crude oil and natural gas, helping to remove impurities that could affect the quality and safety of the final products.

Furthermore, the aerospace and automotive industries utilize metal filter elements to enhance the performance of fuel and lubricant systems, ensuring that engines operate efficiently and reliably.

Maintenance of Metal Filter Elements

To maximize the lifespan and effectiveness of metal filter elements, regular maintenance is essential. This includes periodic inspection for signs of wear or damage and thorough cleaning to remove accumulated particulates. Depending on the application and operating conditions, washing can be done using chemical solvents, ultrasonic cleaning, or backflushing techniques.

Implementing a scheduled maintenance program will not only extend the lifespan of the filters but also ensure optimal filtration performance and prevent costly disruptions in production.

Conclusion

Metal filter elements are indispensable components across various industrial applications due to their durability, efficiency, and versatility. As industries continue to advance and prioritize sustainability, the role of metal filters in maintaining operational excellence and product quality will only become more significant. By investing in high-quality metal filter elements and implementing effective maintenance practices, businesses can enhance their production processes and achieve their operational goals while minimizing environmental impact.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: