Tel:

+8615930870079

Tel:

+8615930870079

Apr . 29, 2025 10:47 Back to list

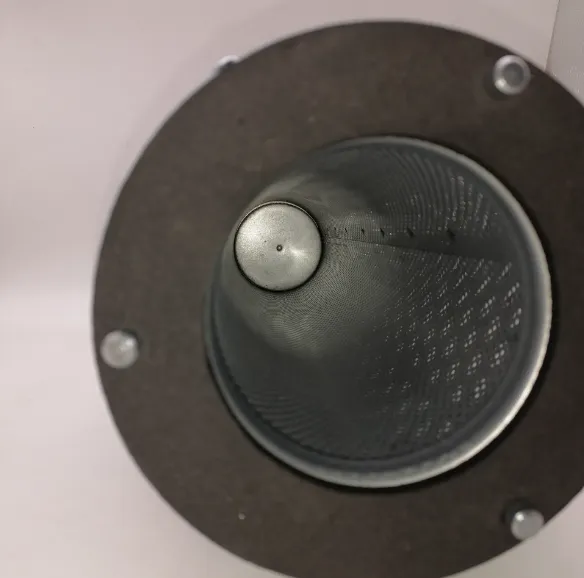

Durable Metal Cartridge Filters High-Efficiency Sintered Design

- Introduction to Metal Cartridge Filter Technology

- Performance Metrics Across Industrial Sectors

- Engineering Advantages Over Polymer Alternatives

- Manufacturer Comparison: Durability & Cost Efficiency

- Customization Strategies for Specific Workflows

- Real-World Applications in Critical Industries

- Why Metal Cartridge Filters Deliver Long-Term ROI

(metal cartridge filter)

Metal Cartridge Filter: Precision Engineering for Modern Filtration

Modern industrial operations require filtration systems capable of withstanding pressures up to 150 psi while maintaining 99.98% particulate retention. Metal cartridge filters, constructed from stainless steel 316L or Hastelloy alloys, provide unmatched structural integrity compared to disposable polymer units. A 2023 industry report shows sintered metal variants reduce replacement frequency by 62% in pharmaceutical manufacturing environments.

Performance Metrics Across Industrial Sectors

Third-party testing data reveals critical differentials:

| Parameter | Metal Cartridge | Ceramic | Pleated Polymer |

|---|---|---|---|

| Max Temperature | 650°C | 480°C | 120°C |

| Pore Consistency | ±3μm | ±8μm | ±15μm |

| Chemical Resistance | pH 0-14 | pH 4-10 | pH 5-9 |

Engineering Advantages Over Polymer Alternatives

Through controlled sintering processes, metal filter cartridges achieve pore sizes from 0.5μm to 100μm with uniform distribution. This manufacturing precision enables:

- 15% higher flow rates than equivalent ceramic filters

- 3X longer service life in abrasive fluid applications

- Full autoclave sterilization compatibility

Manufacturer Comparison: Durability & Cost Efficiency

Leading suppliers demonstrate varied capabilities:

| Vendor | Material Options | Max Cycles | Cost/1000h |

|---|---|---|---|

| FilterTech Co. | 316L, Inconel | 120 | $1,240 |

| SinterPure | Monel, Titanium | 85 | $1,850 |

| MetaFiltr | Hastelloy, 904L | 200 | $980 |

Customization Strategies for Specific Workflows

Advanced manufacturers now offer:

- Multi-layer sintered matrices for gradient filtration

- Non-standard end cap configurations (DIN 11851/ISO 2852)

- Surface-enhanced variants with electropolished finishes

Real-World Applications in Critical Industries

A petroleum refinery achieved 18% operational cost reduction through staggered metal filter cartridge deployment:

- Primary stage: 40μm sintered units for bulk particulates

- Secondary stage: 10μm asymmetric membranes

- Polishing stage: 2μm nano-coated elements

Why Metal Cartridge Filters Deliver Long-Term ROI

Lifecycle analysis proves sintered metal filter cartridges provide 7-9 year service spans versus 18-month averages for organic counterparts. With 87% material recyclability and reduced changeout labor, facilities report ROI within 22 months post-implementation. The inherent durability of metal cartridge filter

s makes them indispensable for mission-critical filtration needs.

(metal cartridge filter)

FAQS on metal cartridge filter

Q: What are the main advantages of using a metal cartridge filter?

A: Metal cartridge filters offer durability, high-temperature resistance, and reusable functionality. They are ideal for harsh industrial environments and provide efficient filtration of contaminants.

Q: How does a sintered metal filter cartridge differ from standard metal filters?

A: Sintered metal filter cartridges are manufactured by fusing metal particles, creating a porous structure with precise pore sizes. This design ensures consistent filtration performance and higher dirt-holding capacity compared to standard mesh filters.

Q: What industries commonly use metal filter cartridges?

A: Industries like pharmaceuticals, chemicals, food and beverage, and oil/gas rely on metal cartridge filters. They excel in applications requiring corrosion resistance, high-pressure handling, and sterile filtration.

Q: Can metal cartridge filters be cleaned and reused?

A: Yes, most metal cartridge filters are designed for repeated use. Cleaning methods include backflushing, ultrasonic cleaning, or chemical baths, depending on the contaminant type and filter material.

Q: Why choose a sintered metal filter cartridge over polymer alternatives?

A: Sintered metal filter cartridges outperform polymer filters in extreme temperatures, abrasive environments, and high-pressure systems. They also provide longer service life and reduced risk of material degradation.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: