Tel:

+8615930870079

Tel:

+8615930870079

Aug. . 07, 2025 03:40 Back to list

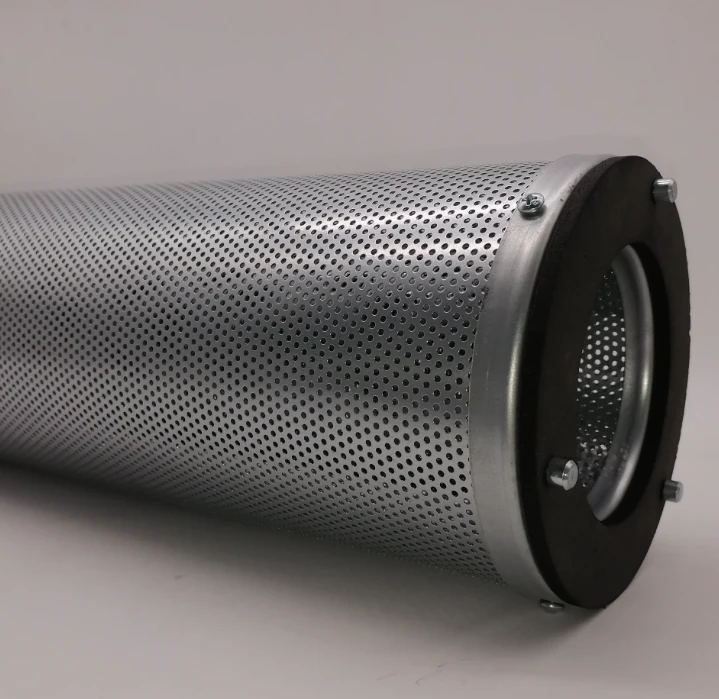

Hot-Sale High Quality Activated Carbon Filter Elements

In an era defined by increasing environmental awareness and stringent quality demands, the importance of advanced filtration solutions cannot be overstated. From industrial processes to municipal water supplies, the need for pure, uncontaminated fluids and gases is paramount. At the heart of many critical filtration systems lies the activated carbon filter element, renowned for its exceptional adsorption capabilities. Among the leading innovations in this field is the **Hot-Sale High Quality Activated Carbon Filter Element**, a product engineered to deliver unparalleled performance and reliability across diverse applications.

Industry Trends and the Growing Demand for Advanced Filtration

The global filtration market is experiencing robust growth, driven by several key trends. Stricter environmental regulations, particularly concerning wastewater discharge and air emissions, are compelling industries to invest in more efficient filtration technologies. Public health concerns are also escalating the demand for potable water and clean air, pushing for superior purification methods. The rise of industrialization in developing economies, coupled with an aging infrastructure in developed nations, further fuels the market for high-performance filtration components. Activated carbon, specifically in the form of a filter element, plays a pivotal role in meeting these demands due to its porous structure and high surface area, enabling effective removal of organic compounds, chlorine, odors, and colors.

According to a report by Grand View Research, the global activated carbon market size was valued at USD 5.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.2% from 2023 to 2030. This growth is largely attributed to its increasing adoption in water treatment, air purification, and industrial applications, underscoring the critical role of products like the **Hot-Sale High Quality Activated Carbon Filter Element** in modern infrastructure and industry.

Understanding the Hot-Sale High Quality Activated Carbon Filter Element

The **Hot-Sale High Quality Activated Carbon Filter Element** is a sophisticated filtration device designed to remove impurities from liquids and gases through the process of adsorption. It leverages the highly porous nature of activated carbon, which is produced by treating carbonaceous materials (like coconut shells, wood, or coal) to create an intricate network of pores. These pores, ranging from micropores (less than 2 nm) to mesopores (2-50 nm) and macropores (greater than 50 nm), provide an immense surface area for contaminants to adhere to.

This product excels in situations requiring high purity levels, odor elimination, chlorine removal, and the reduction of various organic pollutants, including volatile organic compounds (VOCs). Its high efficacy makes it indispensable in applications where both performance and longevity are critical.

Key Specifications and Parameters

The performance of any filter element is quantified by its technical specifications. For the **Hot-Sale High Quality Activated Carbon Filter Element**, these parameters are meticulously controlled to ensure optimal filtration efficiency and durability. Below is a comprehensive table detailing typical specifications:

| Parameter | Typical Value/Range | Units | Description |

|---|---|---|---|

| Filter Media | High-Quality Granular or Extruded Activated Carbon (Coconut Shell/Coal-based) | - | Provides excellent adsorption capacity and low ash content. |

| Micron Rating | 1 - 20 | µm (microns) | Nominal filtration for particulate removal. |

| Outside Diameter (OD) | 2.5, 4.5, 6.0, etc. | inches | Common industry standard sizes. |

| Length | 10, 20, 30, 40, etc. | inches | Standard lengths for various housing configurations. |

| Max Operating Temp. | 52 - 80 | °C | Temperature limit for continuous operation to prevent media degradation. |

| Max Operating Pressure | 7 - 10 | bar | Pressure limit to prevent structural failure. |

| Initial Pressure Drop | < 0.2 | bar @ specified flow | Indicates the resistance to flow; lower is better. |

| Iodine Adsorption Value | 900 - 1100 | mg/g | Measure of micropore volume and activity; higher is better. |

| CTC (Carbon Tetrachloride) Adsorption | 50 - 70 | % (w/w) | Measure of ability to adsorb volatile organic compounds. |

| Ash Content | < 5 | % (w/w) | Lower ash content indicates higher purity of carbon. |

| pH Range | 2 - 12 | - | Operating pH range where the filter maintains integrity and performance. |

| Flow Rate | Varies by size and application | LPM (liters per minute) / GPM (gallons per minute) | Determines how much fluid can be processed per unit time. |

| End Cap Material | PP (Polypropylene), PVC, Nylon | - | Selected for chemical compatibility and durability. |

| Gasket/Seal Material | Buna-N, Silicone, EPDM | - | Ensures leak-proof seal, compatible with fluid. |

| Standards Compliance | NSF/ANSI 42, FDA CFR Title 21 | - | Indicates safety and performance for drinking water applications. |

These precise parameters ensure that the **Hot-Sale High Quality Activated Carbon Filter Element** consistently meets or exceeds the most demanding filtration requirements.

The Meticulous Manufacturing Process of Hot-Sale High Quality Activated Carbon Filter Element

The creation of a high-performance **Hot-Sale High Quality Activated Carbon Filter Element** is a complex process that demands precision engineering and stringent quality control at every stage. This multi-step manufacturing journey ensures the product's superior adsorption capacity, structural integrity, and long service life. The primary manufacturing processes involve extrusion or block formation of activated carbon, followed by critical assembly steps.

Manufacturing Process Overview

While specific proprietary details vary, the general workflow for producing a high-quality activated carbon filter element can be illustrated as follows:

1. Raw Material Sourcing & Pre-treatment

High-quality raw materials such as coconut shells, coal, or wood are selected. These materials undergo crushing, screening, and washing to remove impurities. For example, coconut shell carbon, known for its high microporosity, is often preferred for water treatment applications.

2. Carbonization

The pre-treated raw material is heated in an inert atmosphere (e.g., nitrogen) at temperatures between 600-900°C. This process removes non-carbon elements, leaving a carbonaceous char with rudimentary pore structures. This stage is crucial for developing the foundational carbon matrix.

3. Activation

The carbonized material is subjected to activation, typically through steam activation (physical activation) or chemical activation (e.g., using phosphoric acid or zinc chloride). During steam activation (800-1000°C), steam reacts with the carbon, creating and expanding pores, dramatically increasing the surface area and adsorption sites. This is where the activated carbon gains its powerful adsorbent properties, achieving iodine values often exceeding 1000 mg/g.

4. Grinding & Blending

The activated carbon is then ground to the desired particle size. For extruded or block filters, the activated carbon is blended with a food-grade polymer binder (e.g., polyethylene or polypropylene) and often other additives to enhance structural integrity or specific filtration properties. This blend ensures the carbon particles are uniformly dispersed.

5. Extrusion/Molding (Block Formation)

The blended mixture is then extruded through a die or molded under high pressure and temperature to form a solid, porous block or cylinder. This step creates a uniform pore structure throughout the filter element, crucial for consistent flow and filtration performance. Unlike loose granular carbon, the block form prevents channeling and ensures maximum contact time with the filtration media.

6. Curing & Cooling

The extruded or molded carbon blocks are cured to set the binder and then carefully cooled to prevent cracking or deformation. This step solidifies the filter element's structure.

7. End Cap & Gasket Assembly

Precision-machined end caps (typically made of polypropylene, PVC, or nylon for chemical compatibility) are thermally bonded or integrally molded onto the carbon block. Gaskets (Buna-N, silicone, EPDM) are then installed to ensure a leak-proof seal within the filter housing. This assembly must meet strict ANSI standards for fitment.

8. Quality Control & Testing

Each **Hot-Sale High Quality Activated Carbon Filter Element** undergoes rigorous testing. This includes dimensional checks, burst pressure tests, initial pressure drop measurements, and adsorption capacity verification (e.g., iodine value and CTC removal efficiency as per ASTM standards). Filters designated for potable water applications must comply with NSF/ANSI Standard 42 for chlorine, taste, and odor reduction, and FDA CFR Title 21 for material safety in food contact applications.

9. Packaging & Shipping

Finally, the tested filter elements are individually packaged to prevent contamination and damage during transit, ready for distribution worldwide.

This stringent manufacturing process, involving material selection, precise thermal and chemical treatments, and meticulous assembly, ensures that each **Hot-Sale High Quality Activated Carbon Filter Element** delivered offers exceptional performance, reliability, and an extended service life under diverse operating conditions.

A glimpse into the advanced manufacturing facility producing high-quality activated carbon filter elements, adhering to ISO 9001 standards.

Technical Advantages and Performance Excellence

The **Hot-Sale High Quality Activated Carbon Filter Element** offers a multitude of technical advantages that set it apart in the competitive filtration market. These benefits translate directly into operational efficiencies, cost savings, and enhanced safety for various industries.

- Superior Adsorption Capacity: Utilizing high-grade activated carbon, this filter element boasts an exceptionally high surface area (typically 900-1100 m²/g), maximizing its capacity to adsorb dissolved organic compounds, chlorine, pesticides, herbicides, and other chemical contaminants. The high iodine value is a testament to its extensive microporosity, essential for effective removal of smaller organic molecules.

- Enhanced Chlorine & Odor Removal: Specifically engineered for municipal and industrial water treatment, the element exhibits outstanding capability in reducing chlorine, chloramines, unpleasant tastes, and odors. This is critical for improving water palatability and protecting downstream equipment from chlorine-induced corrosion.

- Low Pressure Drop & High Flow Rates: Despite its dense filtration media, the optimized pore structure and uniform particle distribution ensure a low initial pressure drop, which minimizes energy consumption for pumps and allows for higher flow rates, thereby increasing system efficiency and reducing operational costs.

- Robust Structural Integrity & Longevity: Manufactured through advanced bonding or extrusion techniques, the filter element is designed to withstand higher operating pressures and temperatures without channeling, bypassing, or media shedding. This structural robustness contributes to a longer service life, reducing replacement frequency and maintenance efforts.

- Versatile Chemical Compatibility: Constructed with chemically inert materials for the carbon media, end caps (e.g., polypropylene), and gaskets (e.g., EPDM, Buna-N), the filter exhibits broad chemical compatibility, making it suitable for a wide range of industrial fluids, including mild acids, bases, and various solvents. This anti-corrosion property is vital in harsh chemical environments, such as those found in petrochemical and pharmaceutical industries.

- Reduced Carbon Fines Release: Unlike some granular activated carbon filters, the solid block or extruded design of the **Hot-Sale High Quality Activated Carbon Filter Element** significantly minimizes the release of carbon fines into the filtrate, ensuring cleaner output and protecting sensitive downstream equipment.

- Compliance with International Standards: Adherence to standards like NSF/ANSI 42, FDA CFR Title 21, and ISO 9001 underscores the product's commitment to safety, quality, and performance, providing peace of mind for users in regulated industries.

Extensive Application Scenarios and Industry Impact

The versatility and high performance of the **Hot-Sale High Quality Activated Carbon Filter Element** make it an indispensable component across a vast array of industries and applications:

- Potable Water Treatment: Essential for municipal waterworks and residential filtration systems to remove chlorine, chloramines, organic contaminants, taste, and odor, ensuring safe and pleasant drinking water.

- Industrial Process Water: Used in diverse manufacturing processes where water quality directly impacts product quality or equipment longevity. This includes pre-filtration for reverse osmosis (RO) systems, protecting delicate membranes from chlorine degradation.

- Food & Beverage Industry: Critical for removing impurities that affect taste, color, and odor in beverages (e.g., soft drinks, beer, wine) and for ensuring process water purity for food production. Compliance with FDA standards is paramount here.

- Pharmaceutical & Biotechnology: Employed in the purification of process water, APIs (Active Pharmaceutical Ingredients), and final products, where ultra-pure water is a non-negotiable requirement. Removes organic impurities, pyrogens, and other contaminants.

- Petrochemical Industry: Vital for treating process streams, wastewater, and even gas streams to remove hydrocarbons, oil, phenols, and other organic chemicals, ensuring compliance with environmental regulations and protecting catalytic converters. Its anti-corrosion properties are particularly beneficial in this sector.

- Metallurgy & Mining: Used in effluent treatment to remove heavy metals and organic complexing agents, contributing to environmental compliance and resource recovery.

- Chemical Processing: For purification of various chemical solutions, removal of unwanted by-products, and decolorization processes, enhancing product purity.

- Air Purification: While primarily known for liquid filtration, activated carbon elements are also adapted for air filtration to remove VOCs, odors, and other gaseous pollutants in industrial exhaust, laboratory fume hoods, and HVAC systems.

- Aquaculture & Aquarium Systems: To maintain water clarity and health by removing dissolved organic wastes, medications, and undesirable chemicals.

In each of these sectors, the **Hot-Sale High Quality Activated Carbon Filter Element** delivers consistent, high-level performance, contributing to operational efficiency, regulatory compliance, and product integrity.

A **Hot-Sale High Quality Activated Carbon Filter Element** being installed in a municipal water treatment facility, highlighting its application in ensuring public water safety.

Choosing the Right Partner: Manufacturer Comparison and Selection Criteria

Selecting the right supplier for your **Hot-Sale High Quality Activated Carbon Filter Element** is as crucial as the product itself. The market offers numerous manufacturers, but distinguishing a reliable, high-quality partner requires careful consideration of several factors beyond just price.

Key Factors for Manufacturer Evaluation:

- Expertise and Experience: A leading manufacturer should possess extensive knowledge of filtration science, material properties, and industry-specific challenges. Look for companies with a long history of serving diverse industries, as this indicates a breadth of experience and problem-solving capabilities.

- Quality Control & Certifications: Verify adherence to international quality management systems such as ISO 9001. For activated carbon filters, certifications like NSF/ANSI 42 (for drinking water), FDA CFR Title 21 (for food contact materials), and potentially CE marking are essential. These certifications are independently verified and attest to consistent product quality and safety.

- Research & Development Capabilities: A forward-thinking manufacturer invests in R&D to continuously improve product performance, explore new media formulations, and develop innovative solutions for emerging contaminants. This ensures access to cutting-edge technology.

- Customization and Technical Support: The ability to provide bespoke solutions tailored to unique application requirements (e.g., specific dimensions, unique end-cap configurations, or specialized carbon types) is a significant advantage. Furthermore, robust technical support, including application engineering assistance and troubleshooting, is invaluable.

- Supply Chain Reliability: Assess the manufacturer's capacity for consistent production and on-time delivery. A strong global supply chain ensures product availability and minimizes downtime for your operations.

- Customer Service & After-Sales Support: Responsiveness, clear communication, and comprehensive after-sales service (including warranty, technical assistance, and replacement part availability) are indicators of a reliable partner committed to long-term customer satisfaction.

- Environmental Responsibility: Evaluate the manufacturer's commitment to sustainable practices in their production processes, including responsible sourcing of raw materials and waste management.

While we refrain from direct comparisons to specific competitors, OnlyFilterCartridge.com stands out by excelling in these areas. Our dedication to superior material sourcing, advanced manufacturing technologies, and rigorous quality assurance processes ensures that every **Hot-Sale High Quality Activated Carbon Filter Element** meets the highest industry benchmarks. Our commitment to ISO 9001 standards and customer-centric service has built a reputation for reliability and trust over many years in the filtration industry.

Customization Solutions: Tailored to Your Specific Needs

Recognizing that no two filtration challenges are exactly alike, OnlyFilterCartridge.com offers comprehensive customization options for the **Hot-Sale High Quality Activated Carbon Filter Element**. Our engineering team collaborates closely with clients to design and manufacture filter elements that precisely match their unique operational parameters and contaminant removal targets.

Our Customization Capabilities Include:

- Dimensions: Custom lengths and outside/inside diameters to fit non-standard filter housings or optimize flow dynamics for specific systems.

- Activated Carbon Type: Selection between coconut shell, coal-based, or wood-based activated carbon, each offering distinct pore structures and adsorption properties for targeted contaminant removal (e.g., higher capacity for specific VOCs or heavy metals).

- Binder Material: Choice of different food-grade binders (e.g., polypropylene, polyethylene) to ensure chemical compatibility with process fluids and compliance with relevant industry standards (e.g., FDA).

- End Cap & Gasket Materials: Custom selection of end cap (e.g., PVC, ABS, Nylon) and gasket materials (e.g., Viton, Kalrez, PTFE) to withstand specific temperatures, pressures, and chemical environments, ensuring a secure, leak-proof fit for highly corrosive applications.

- Micron Rating: Adjustments to the nominal micron rating to balance particulate pre-filtration with activated carbon adsorption efficiency.

- Specialized Impregnation: For specific applications, activated carbon can be impregnated with chemicals (e.g., silver for bacteriostatic properties, or potassium iodide for enhanced mercury removal) to enhance performance beyond standard adsorption.

- Flow Configuration: Options for different flow patterns (e.g., radial flow for higher flow rates, axial flow for specific contact time requirements) based on system design.

Our ability to provide these bespoke solutions ensures that clients receive a **Hot-Sale High Quality Activated Carbon Filter Element** that is not merely a component, but an optimized solution for their critical filtration needs. This tailored approach often leads to improved system performance, extended filter life, and significant operational savings.

Real-World Application Cases & Customer Experience

The efficacy and reliability of the **Hot-Sale High Quality Activated Carbon Filter Element** are best demonstrated through its successful deployment in challenging real-world scenarios and the positive feedback from our valued clients.

Case Study 1: Municipal Water Treatment Plant Upgrade

Challenge: A large municipal water treatment plant in North America faced increasing public complaints regarding the "chlorine taste and odor" in their drinking water, despite meeting all regulatory disinfection requirements. The existing granular activated carbon (GAC) beds suffered from channeling issues, leading to inconsistent removal efficiency.

Solution: The plant replaced their GAC media with our **Hot-Sale High Quality Activated Carbon Filter Element** in a custom-designed array. The solid block construction eliminated channeling and provided uniform contact time. We supplied elements with specific dimensions and a high CTC adsorption value to target chloramine removal effectively.

Results: Within weeks, customer complaints dropped by over 90%. The plant reported a consistent >95% reduction in free chlorine and significantly improved taste and odor profiles. The extended lifespan of the new elements also reduced replacement frequency by 30%, leading to considerable operational savings and positive feedback from the public.

Case Study 2: Pharmaceutical Wastewater Treatment

Challenge: A pharmaceutical manufacturing facility needed to treat its wastewater stream, which contained trace amounts of organic pharmaceutical compounds and fine particulates, before discharge. Existing filtration methods were inadequate, failing to meet stringent discharge limits (e.g., COD/BOD levels).

Solution: We provided a customized **Hot-Sale High Quality Activated Carbon Filter Element** with a specific micron rating (5 µm nominal) and a highly porous, high-surface-area activated carbon blend, optimized for the adsorption of complex organic molecules. The end caps and gaskets were selected for their compatibility with the wastewater's chemical composition and temperature.

Results: The facility achieved consistent compliance with discharge regulations. Total Organic Carbon (TOC) levels were reduced by an average of 80%, and particulate removal was highly effective. The robust design of the filter elements ensured consistent performance even under fluctuating flow conditions, avoiding costly penalties and improving their environmental footprint. "The quality and reliability of these activated carbon filters have been a game-changer for our wastewater treatment plant," commented the facility's Chief Engineer.

Advanced filtration systems featuring **Hot-Sale High Quality Activated Carbon Filter Element** are crucial in various industrial applications, ensuring product purity and environmental compliance.

Unwavering Trustworthiness: Quality Assurance and Customer Support

At OnlyFilterCartridge.com, trustworthiness is the cornerstone of our operations. We are committed to delivering not just high-quality products like the **Hot-Sale High Quality Activated Carbon Filter Element**, but also an assurance of reliability, performance, and exceptional customer service. Our dedication is reflected in our adherence to global standards, transparent processes, and robust support systems.

Certifications and Compliance:

Our manufacturing facilities and processes strictly adhere to the ISO 9001:2015 Quality Management System. This certification ensures that our production is consistent, efficient, and continuously improving, leading to superior product quality and reliability. Furthermore, our products intended for potable water applications comply with NSF/ANSI Standard 42 for material safety and performance in chlorine, taste, and odor reduction. Materials used in filter elements for food and beverage or pharmaceutical applications meet FDA CFR Title 21 regulations, guaranteeing their safety for contact with consumables.

Rigorous Quality Assurance & Testing:

Every batch of **Hot-Sale High Quality Activated Carbon Filter Element** undergoes multiple layers of quality control. This includes:

- Raw Material Inspection: Verification of activated carbon's iodine value, ash content, and particle size distribution.

- In-Process Monitoring: Continuous checks during extrusion/molding for consistency in density, hardness, and dimension.

- Finished Product Testing: Each filter element is subjected to:

- Pressure Drop Testing: To ensure optimal flow characteristics.

- Burst Strength Testing: To verify structural integrity under pressure.

- Adsorption Capacity Tests: Using standard challenge tests (e.g., CTC or chlorine reduction) to confirm performance.

- Dimensional Verification: Precise measurement to ensure perfect fit in standard housings.

Warranty & Service Life Commitment:

We stand behind the quality of our **Hot-Sale High Quality Activated Carbon Filter Element** with a comprehensive warranty against manufacturing defects. While actual service life depends on specific application conditions (contaminant load, flow rate, water chemistry), our products are engineered for an extended lifespan, often exceeding industry averages, reducing your total cost of ownership.

Delivery Timelines:

We understand the importance of timely delivery for maintaining operational continuity. Our streamlined production processes and robust logistics network enable us to offer competitive delivery times, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent requirements. Custom orders may have slightly longer lead times, which are communicated transparently at the time of order confirmation.

Dedicated Customer Support:

Our commitment extends beyond product delivery. Our team of experienced technical support specialists is available to assist with product selection, installation guidance, troubleshooting, and optimizing filtration system performance. We offer:

- Pre-sales consultation to identify the best solution.

- Post-sales technical assistance and problem resolution.

- Training and educational resources for proper product usage and maintenance.

This holistic approach to quality and service ensures that our clients not only receive a superior **Hot-Sale High Quality Activated Carbon Filter Element** but also a trusted partner dedicated to their operational success.

Frequently Asked Questions (FAQ) about Activated Carbon Filter Elements

Q1: What is the primary function of a Hot-Sale High Quality Activated Carbon Filter Element?

A1: Its primary function is to remove dissolved organic contaminants, chlorine, chloramines, unpleasant tastes, and odors from liquids (primarily water) and gases through the process of adsorption, where impurities adhere to the extensive surface area of the activated carbon.

Q2: What is the significance of "Iodine Value" in activated carbon?

A2: Iodine Value (measured in mg/g) is a common parameter used to indicate the level of activity of activated carbon. A higher iodine value signifies a greater number of micropores and a larger surface area available for adsorption, particularly of smaller molecular weight compounds like iodine, which correlates to effective removal of organic impurities.

Q3: How does the manufacturing process (e.g., extrusion) impact the performance compared to granular activated carbon (GAC)?

A3: Extrusion or block formation of activated carbon, used in the **Hot-Sale High Quality Activated Carbon Filter Element**, creates a solid, uniform carbon matrix. This prevents channeling (where water bypasses the media), ensures maximum contact time with the carbon, and significantly reduces carbon fines shedding, leading to more consistent performance and cleaner output compared to loose GAC beds.

Q4: What specific standards should a Hot-Sale High Quality Activated Carbon Filter Element comply with for drinking water applications?

A4: For drinking water applications, the filter element should comply with NSF/ANSI Standard 42 for chlorine, taste, and odor reduction. Additionally, the materials used should adhere to FDA CFR Title 21 regulations to ensure they are safe for contact with potable water.

Q5: What are "channeling" and "media shedding," and how does this product address them?

A5: Channeling occurs in loose media beds when water finds paths of least resistance, bypassing significant portions of the filter media, reducing effectiveness. Media shedding refers to the release of small carbon particles (fines) into the filtered water. The solid, extruded block design of this **Hot-Sale High Quality Activated Carbon Filter Element** eliminates channeling by forcing water uniformly through the matrix and minimizes fines release due to its stable structure and binding agents.

Q6: Can this activated carbon filter remove heavy metals or specific chemical compounds?

A6: While standard activated carbon primarily removes organic compounds and chlorine through adsorption, some specialized **Hot-Sale High Quality Activated Carbon Filter Element** can be impregnated with specific chemicals (e.g., KMn04 for H2S, or silver for bacteriostatic properties, or certain resins for heavy metals) to enhance their capacity to remove specific heavy metals, certain inorganic compounds, or bacteria.

Q7: What is the typical lifespan of a Hot-Sale High Quality Activated Carbon Filter Element?

A7: The lifespan varies significantly depending on the influent water quality (contaminant load), flow rate, and the size of the filter. Generally, for residential applications, it can be 6-12 months. In industrial settings, depending on the application and contaminant levels, it could range from a few weeks to several months. Regular monitoring of pressure drop and effluent quality is recommended to determine optimal replacement intervals.

References and Further Reading:

For more in-depth information on activated carbon technology and market trends, consider the following resources:

- Grand View Research Report: "Activated Carbon Market Size, Share & Trends Analysis Report By Product (PAC, GAC), By Application (Water Treatment, Air Purification, Food & Beverage), By End-use (Industrial, Residential, Commercial), And Segment Forecasts, 2023 - 2030." https://www.grandviewresearch.com/industry-analysis/activated-carbon-market

- Journal of Water Process Engineering: "Adsorption of emerging contaminants by activated carbon: A review." https://www.sciencedirect.com/journal/journal-of-water-process-engineering (Search for relevant articles within the journal using keywords like "activated carbon adsorption" or "water treatment")

- International Journal of Environmental Research and Public Health: "Applications of Activated Carbon in Water and Wastewater Treatment: A Review." https://www.mdpi.com/journal/ijerph (Search for relevant articles within the journal using keywords like "activated carbon filter" or "water purification")

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: