Tel:

+8615930870079

Tel:

+8615930870079

Dez . 19, 2024 07:50 Back to list

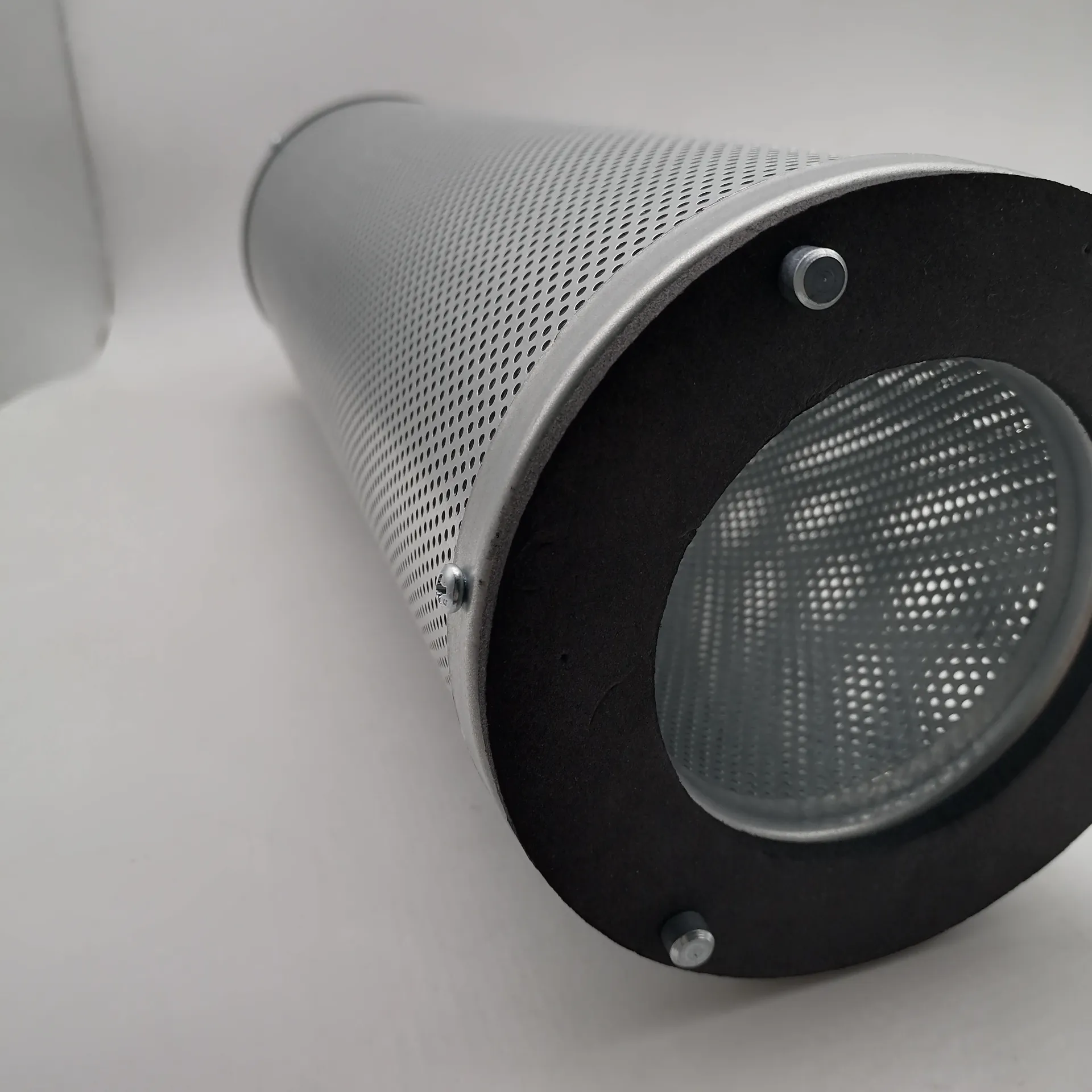

gas turbine air intake filter

The Importance of Gas Turbine Air Intake Filters

Gas turbines are critical components in a variety of applications, including power generation and aviation. Their efficiency and reliability significantly depend on the clean and uninterrupted airflow into the turbine. This is where gas turbine air intake filters come into play. These filters serve a vital function, ensuring that the air entering the turbine is free from contaminants that can harm its components and degrade its performance.

The Role of Air Intake Filters

Air intake filters are designed to capture airborne particles such as dust, dirt, pollen, and other debris that can adversely affect turbine operation. The air that enters a gas turbine is vital for the combustion process, as it must be at an optimal quality to ensure efficient energy conversion. Unfiltered or poorly filtered air can lead to several issues, including

1. Erosion of Compressor Blades Impurities in the air can cause erosion of the blades within the compressor. This can lead to reduced efficiency and, ultimately, increased operational costs. When the blades wear down, the turbine requires more energy to produce the same output, resulting in higher fuel consumption and reduced economic performance.

2. Decreased Efficiency Contaminants can disrupt the airflow patterns within the turbine, causing turbulence and inefficiencies. When the air is not clean, the combustion process can become less efficient, leading to incomplete fuel combustion. This inefficiency results in increased emissions and can adversely affect the turbine’s performance, reliability, and longevity.

3. Increased Maintenance Costs Operating a gas turbine with inadequate air filtration can lead to more frequent maintenance and repairs. The presence of contaminants accelerates wear and tear, necessitating earlier component replacements. Consequently, this results in higher maintenance costs and potential downtime, which can be particularly problematic in sectors where turbines are a primary energy source.

Types of Air Intake Filters

There are several types of air intake filters used in gas turbines, each offering different levels of filtration efficiency

. The most common types includegas turbine air intake filter

- Panel Filters These are designed to remove larger particles from the air and are often the first line of defense against contaminants. However, they may not be sufficient for finer particles.

- Bag Filters This type can capture smaller particles and provide greater surface area for filtration. Bag filters are often used in conjunction with panel filters to enhance overall filtration efficiency.

- Absolute Filters These are designed for high-efficiency air filtration and can capture even the tiniest particles. They are crucial in environments where air quality is of utmost importance, such as in the aviation industry.

The Importance of Regular Maintenance

The effectiveness of air intake filters relies heavily on their proper maintenance. Regular inspections and timely replacement of filters are essential to maintain optimal performance. The frequency of replacement depends on several factors, including the operating environment, the level of contaminants, and the specific design of the filtration system.

In dusty or industrial environments, filters may need to be replaced more frequently to ensure that the turbine operates efficiently. Additionally, advancements in technology have led to the development of filters with improved materials and designs, allowing for better performance and longer service life.

Conclusion

Gas turbine air intake filters are indispensable for maintaining the efficiency and reliability of gas turbines. By filtering out harmful contaminants, these filters protect critical turbine components from erosion, contribute to improved combustion efficiency, and help minimize maintenance costs. As energy demands continue to grow across various sectors, investing in high-quality air intake filtration systems and adhering to regular maintenance schedules will be crucial in ensuring the long-term performance of gas turbines. Proper filtration not only enhances operational efficiency but also plays a vital role in sustaining the integrity of the environment by minimizing emissions and maximizing the effectiveness of energy conversion processes.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: