Tel:

+8618931101301

Tel:

+8618931101301

Aug. . 12, 2024 07:36 Back to list

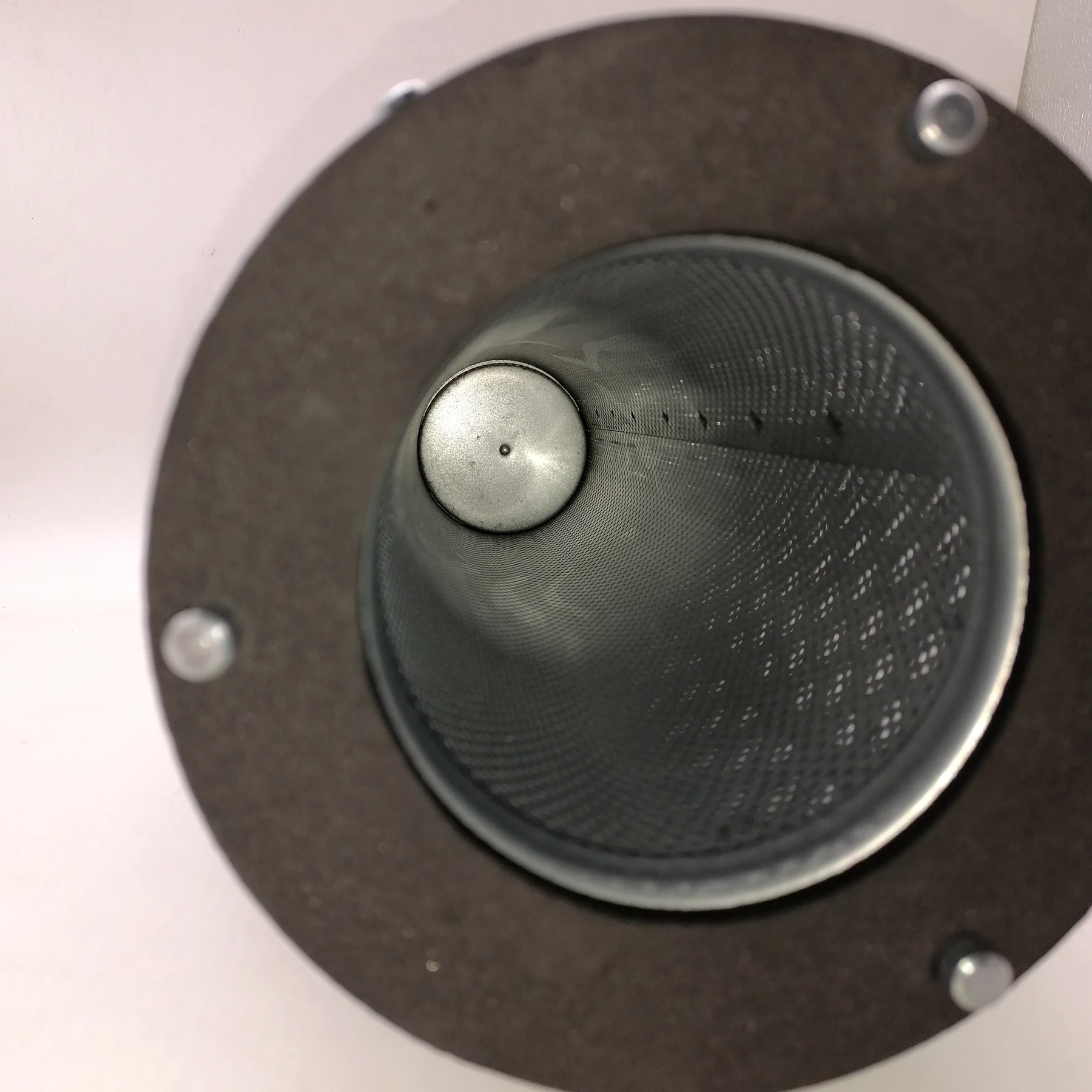

Efficient Dust Collection System Utilizing Advanced Filter Cartridge Technology for Industrial Applications

Understanding Filter Cartridges in Dust Collectors

In various industrial settings, dust collectors play a crucial role in maintaining air quality and ensuring the safety of personnel by capturing harmful airborne particles. Among the key components of these systems are filter cartridges, which significantly influence the efficiency and effectiveness of dust collection processes. This article explores the importance of filter cartridges, their types, maintenance, and their role in enhancing industrial operations.

What is a Filter Cartridge?

A filter cartridge is a critical component of a dust collector that captures particles from the air, preventing them from being released back into the workplace environment. These cartridges are designed to trap a wide variety of contaminants, including dust, mold, pollen, and even harmful chemicals. Typically made from materials such as polyester, polypropylene, or fiberglass, filter cartridges can be customized to meet specific filtration needs, depending on the type of industry and the nature of the dust being collected.

Types of Filter Cartridges

Filter cartridges come in various designs and configurations to accommodate different dust collector systems

1. Nominal Filters These filters are designed to remove particles of a specific size range and are often used for general applications. They are cost-effective and suitable for environments with moderate dust levels.

2. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture 99.97% of particles as small as 0.3 microns. They are ideal for environments requiring stringent air quality standards, such as pharmaceuticals, food processing, and microelectronics.

3. Activated Carbon Filters These filters are combined with activated carbon to capture harmful gases and odors in addition to particulate matter. They are essential in industries where volatile organic compounds (VOCs) are a concern.

filter cartridge dust collector

4. Specialized Filters Some applications require filters that can withstand high temperatures or are resistant to specific chemicals. These specialized cartridges are critical in industries such as metalworking and chemical manufacturing.

Importance of Maintenance

Regular maintenance of filter cartridges is essential for ensuring the optimal performance of dust collectors. Over time, filters can become clogged with dust and debris, leading to reduced airflow and increased energy consumption. Here are some key maintenance practices

- Regular Inspection Periodically check filter cartridges for signs of wear, damage, or clogging. Visual inspections can often reveal whether a filter needs cleaning or replacement.

- Cleaning Many filter cartridges can be cleaned and reused. Cleaning methods vary, including shaking, using compressed air, or ultrasonic cleaning, depending on the type of material.

- Replacement When filters become excessively clogged or damaged, replacement is necessary to maintain efficiency and safety. Keeping a schedule for regular replacements can prevent unexpected downtimes.

Enhancing Industrial Operations

Investing in high-quality filter cartridges and maintaining them is essential not just for compliance with health and safety regulations but also for the overall efficiency of industrial operations. Clean air can lead to improved worker productivity and morale, ultimately benefiting the bottom line. Furthermore, effective dust collection helps in extending the life of machinery and reducing the frequency of repairs, thus saving costs in the long run.

In conclusion, filter cartridges are a vital component of dust collectors in various industries. Understanding their types, maintaining them regularly, and investing in quality products can significantly enhance workplace safety and efficiency. As industries continue to prioritize air quality and worker health, the role of filter cartridges will remain indispensable in achieving these crucial goals.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: