Tel:

+8615930870079

Tel:

+8615930870079

Sep . 23, 2024 05:07 Back to list

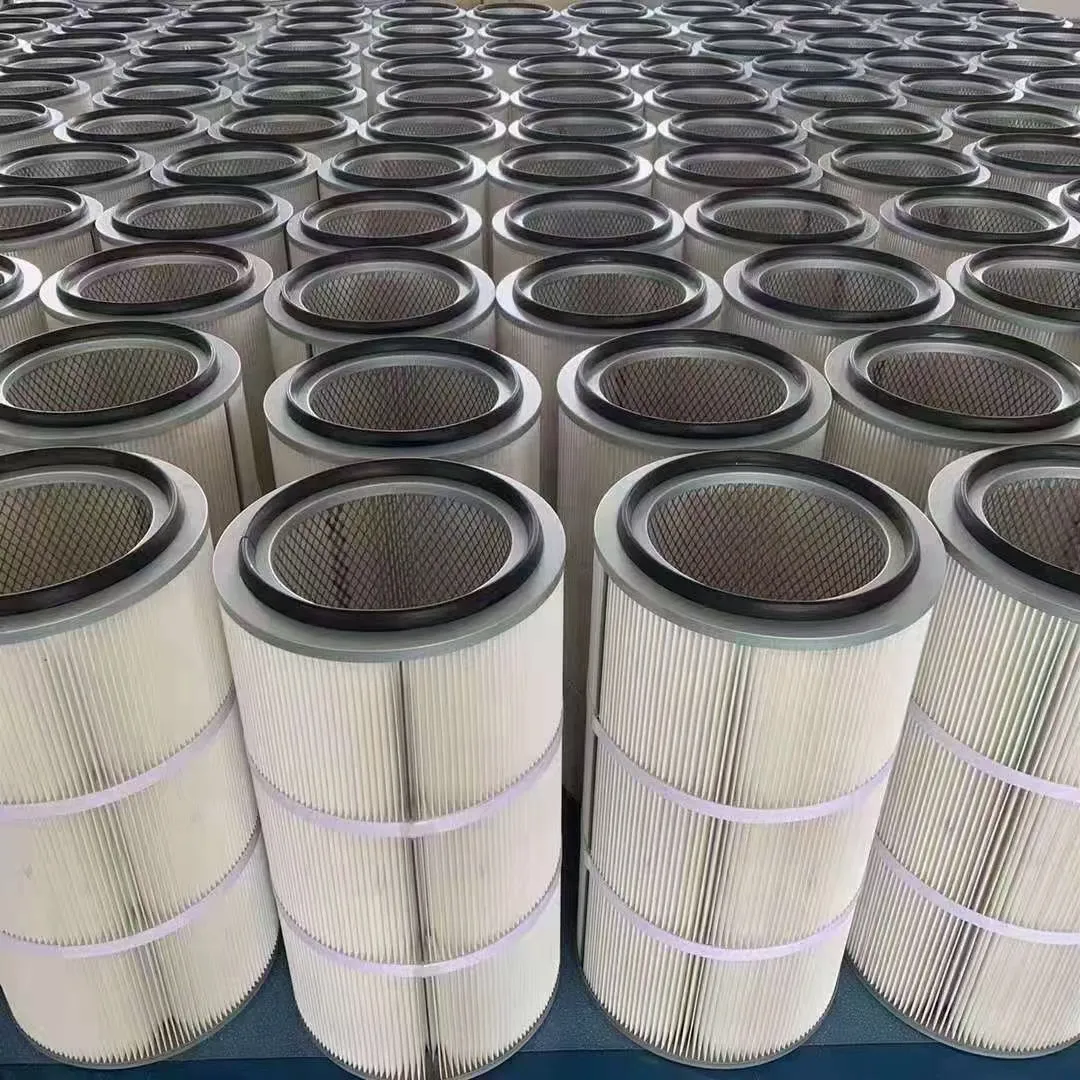

dust extractor pleated filter cartridges

Understanding Dust Extractor Pleated Filter Cartridges

In various industrial and manufacturing environments, maintaining air quality is crucial for both health and productivity. One of the key components in dust extraction systems is the pleated filter cartridge, which plays a significant role in trapping airborne particles and ensuring that the air is clean and safe to breathe.

What are Pleated Filter Cartridges?

Pleated filter cartridges are specialized air filters designed to maximize surface area while minimizing resistance to airflow. Their pleated design includes numerous folds that increase the filter’s effective surface area without increasing its size. This geometric configuration allows for greater dust-holding capacity and enhanced filtration efficiency compared to traditional flat filters.

These cartridges are typically made from a variety of materials, including polyester, polypropylene, or cellulose, depending on the specific application and environmental conditions. The choice of material affects not only the level of filtration but also the filter's resistance to moisture and chemicals, which are significant factors in industrial settings.

How Do They Work?

Dust extractor pleated filter cartridges operate on a straightforward principle as air flows through the filtration media, particles are trapped in the filter fibers, while clean air passes through

. The pleated design facilitates a larger volume of air to be filtered simultaneously, making these cartridges effective for high dust-load applications commonly found in woodworking, metalworking, food processing, and other industries.When the cartridge is new and clean, it has a lower pressure drop, allowing for efficient airflow. However, as dust accumulates on the surface, the pressure drop increases, leading to a decrease in airflow efficiency. Therefore, it is essential to perform regular maintenance, including cleaning or replacing the cartridges as needed.

dust extractor pleated filter cartridges

Advantages of Pleated Filter Cartridges

1. High Filtration Efficiency The pleated design ensures that a significant amount of dust and particulate matter is captured, which helps maintain a cleaner environment and reduces machine wear caused by abrasive particles.

2. Longer Lifespan Due to their larger surface area, pleated filter cartridges can hold more dust than traditional filters before needing replacement. This results in less frequent maintenance and reduced operational costs.

3. Improved Airflow The design allows for better airflow at lower pressure drops, which enhances the overall efficiency of the dust extraction system and reduces energy consumption.

4. Versatility These cartridges can be customized to suit a wide range of applications and environments, including those that are particularly demanding or require specialized filtration media.

Conclusion

In industrial environments where dust and particulate matter are prevalent, installing dust extractor pleated filter cartridges is of paramount importance. They not only contribute to cleaner air and improved operational efficiency but also safeguard the health of workers and the longevity of equipment. When selecting a pleated filter cartridge, it is vital to consider factors such as the type of dust being collected, the specific application, and compatibility with the dust extraction system. Regular maintenance and timely replacement of these cartridges will ensure optimal performance and a safer working environment. Investing in quality pleated filter cartridges is an investment in productivity, health, and sustainability.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: