Tel:

+8618931101301

Tel:

+8618931101301

Nov . 10, 2024 02:04 Back to list

Exploring the Benefits of Dust Cartridge Filtration in Air Quality Management

Understanding Dust Cartridge The Silent Guardian of Clean Environments

In modern technology and manufacturing, the significance of clean environments cannot be overstated. Industries ranging from pharmaceuticals to electronics must maintain high standards of cleanliness to ensure product quality and safety. At the heart of these clean operations lies a crucial component known as the dust cartridge. This article delves into what dust cartridges are, their importance, and how they function in various applications.

What is a Dust Cartridge?

A dust cartridge is a specialized filter designed to capture and collect airborne particles, dust, and other contaminants that can compromise product integrity or worker safety. Often constructed from polyester, cellulose, or fiberglass materials, these cartridges are an integral part of dust collection systems used in industrial facilities. They are engineered to fit into specific dust collectors, enabling them to trap particles efficiently while allowing clean air to flow through.

Importance in Various Industries

1. Pharmaceutical Industry In the pharmaceutical sector, the presence of dust or particulate matter can lead to contamination of products, resulting in safety risks and regulatory issues. Dust cartridges are instrumental in ensuring that the environment remains sterile, thereby protecting both the products and the consumers.

2. Electronics Manufacturing The production of electronic components requires immaculate conditions; even the smallest dust particle can disrupt the assembly of sensitive parts. Dust cartridges play a vital role in maintaining a cleanroom atmosphere, so manufacturers can produce defect-free products.

3. Food and Beverage Industry Just as in pharmaceuticals, hygiene is paramount in food processing. Dust cartridges help control the dust levels, preventing contamination and ensuring compliance with health regulations.

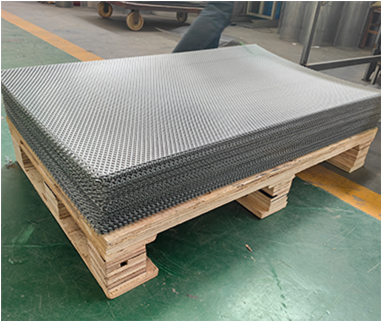

dust cartridge

4. Construction Industry In construction sites, the presence of silica dust and other harmful particles can pose serious health risks to workers. Utilizing dust cartridges in vacuum systems helps mitigate these dangers by capturing harmful dust before it can be inhaled.

How Dust Cartridges Work

Dust cartridges function based on a filtration process that captures airborne particles. When air containing dust particles enters the dust collection system, it passes through the cartridge. The filter media within the cartridge has a varied pore size, allowing smaller particles to be trapped while clean air is expelled back into the environment.

Over time, as the particles accumulate, the cartridge can become clogged, leading to a decrease in efficiency. Regular maintenance, including cleaning or replacing cartridges, is crucial to ensure optimal performance. Most systems are designed to allow for easy access to the cartridges, facilitating timely replacements.

Advancements in Dust Cartridge Technology

Advancements in technology have led to the development of more efficient dust cartridge designs. Features such as pleated filter media increase the surface area for better dust capture without significantly raising airflow resistance. Additionally, some modern cartridges are treated with coatings that enhance their ability to repel dust and improve cleaning efficiency.

Conclusion

In conclusion, dust cartridges are an essential component in maintaining clean and safe environments across various industries. They ensure that airborne contaminants do not compromise product quality or worker health. As industries continue to evolve, advancements in dust cartridge technology will further enhance their effectiveness, making them an indispensable part of modern manufacturing and processing systems. By investing in high-quality dust cartridges, businesses can uphold their commitments to quality and safety while fostering a healthier workplace.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: