Tel:

+8615930870079

Tel:

+8615930870079

Sep . 21, 2024 14:25 Back to list

cartridge dust collector filter

Understanding Cartridge Dust Collector Filters

In industries where dust and particulate matter are prevalent, effective air filtration is crucial for maintaining a safe and productive working environment. One of the most efficient solutions in this regard is the cartridge dust collector filter. These filters play a vital role in capturing airborne particles and ensuring air quality, while also contributing to the operational efficiency of various manufacturing processes.

What is a Cartridge Dust Collector Filter?

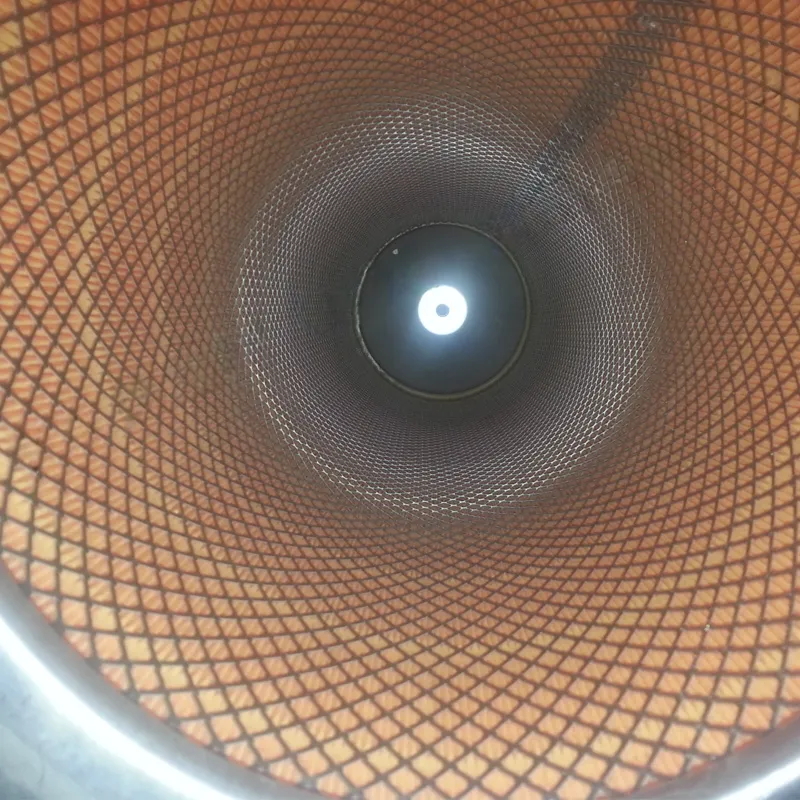

Cartridge dust collector filters are cylindrical filters made from advanced filtration materials that are designed to capture dust and other particulate matter from the air. The cartridge design allows for a large surface area, which enhances the filter's efficiency and its ability to trap even the finest particles. Typically housed in a dust collector system, these filters work by drawing air through the filter media. The captured dust particles are then removed from the air stream, preventing them from re-entering the environment.

How Do They Work?

The operation of a cartridge dust collector filter is straightforward yet effective. When industrial processes generate airborne dust, the dust collector system creates negative pressure to pull the contaminated air through the filter. As air passes through the filter, the filter media captures particles based on their size and weight. Over time, as more dust accumulates on the filter surface, the air velocity through the filter decreases, which can lead to a drop in the system's efficiency. To counter this, many systems are equipped with automatic cleaning mechanisms that use compressed air to dislodge the accumulated dust, allowing for continuous operation with minimal downtime.

Advantages of Cartridge Filters

Cartridge dust collector filters offer numerous benefits that make them a preferred choice in many industrial settings

cartridge dust collector filter

1. High Filtration Efficiency The design and material of cartridge filters enable them to capture a wide range of particulate sizes, including fine particles that may be harmful to health.

2. Reduced Maintenance With automatic cleaning systems, the maintenance requirements for cartridge filters are significantly lower compared to traditional bag filters, resulting in reduced labor and operational costs.

3. Space Efficiency The compact design of cartridge filters allows them to fit into smaller spaces. This is especially beneficial in facilities with limited floor space.

4. Enhanced Durability Cartridge filters are often made from robust materials designed to withstand harsh industrial environments. This longevity translates into longer replacement intervals and reduced costs over time.

5. Environmental Compliance By effectively capturing dust and pollutants, these filters help industries comply with environmental regulations, promoting cleaner air and safer workplaces.

Conclusion

In conclusion, cartridge dust collector filters are an essential component in many industrial operations, providing efficient air filtration and contributing to workplace safety and environmental stewardship. By investing in high-quality cartridge filters and dust collector systems, facilities can not only improve air quality but also enhance their overall operational efficiency. As industries continue to prioritize sustainability and health standards, the role of cartridge dust collector filters will only become more prominent, solidifying their place as a cornerstone of effective air management in the work environment.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: