Tel:

+8615930870079

Tel:

+8615930870079

Nov . 27, 2024 21:28 Back to list

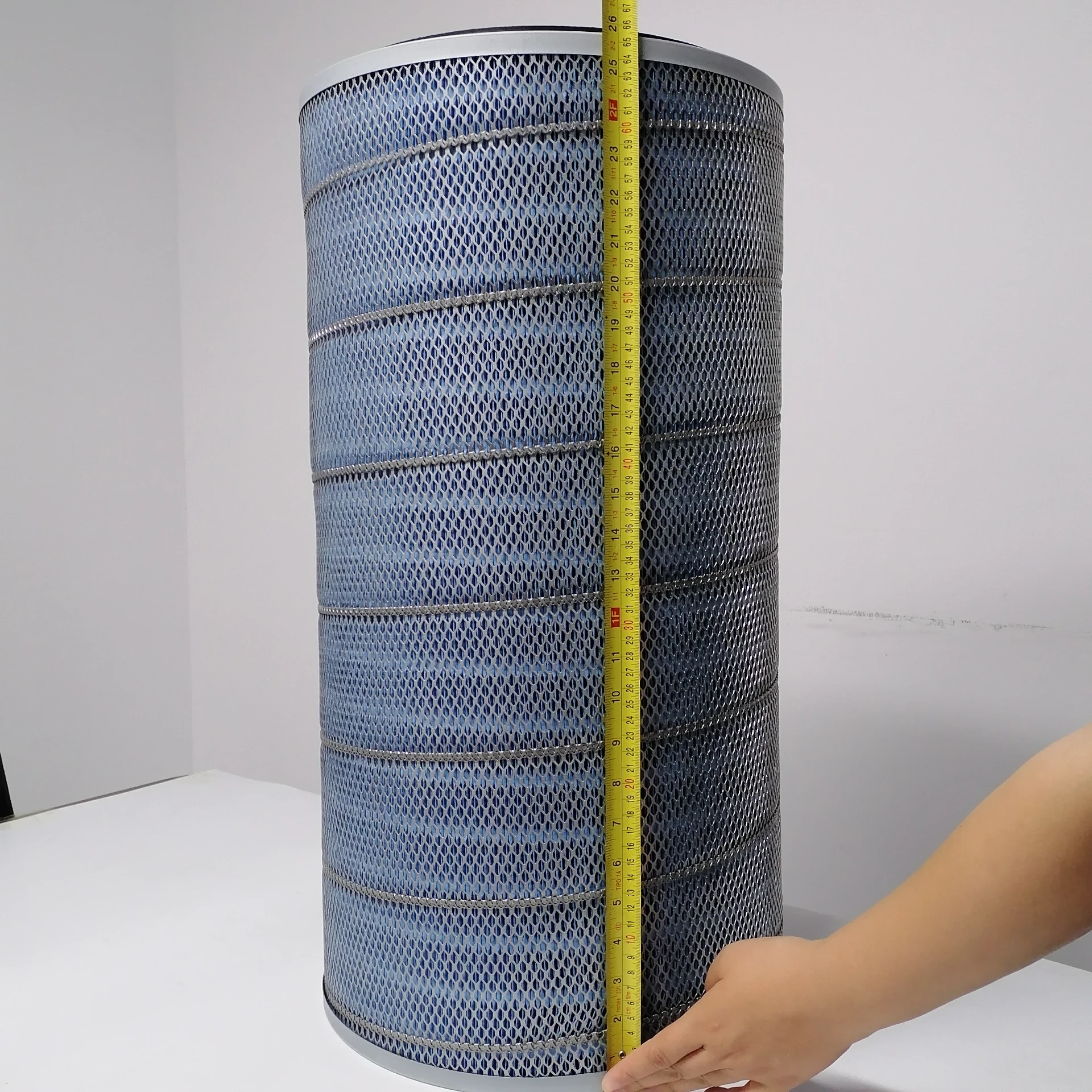

Antistatic Filter Element for Enhanced Dust Control and Air Quality Improvement

Understanding Antistatic Filter Elements An Essential Component for Clean Environments

In various industries, maintaining a clean and controlled environment is paramount. One critical component that contributes to this goal is the antistatic filter element. As technology advances and industries evolve, the role of filtration systems becomes increasingly important, particularly in environments sensitive to static electricity and airborne contaminants. This article explores the significance, functionality, and applications of antistatic filter elements.

What is an Antistatic Filter Element?

An antistatic filter element is designed to reduce static electricity build-up while filtering out airborne particles and pollutants. These filters are commonly used in industrial applications, laboratories, electronic manufacturing environments, and other settings where static discharge can lead to equipment damage or compromises in product quality.

Static electricity is generated through various processes, including friction and the movement of materials. In environments like semiconductor manufacturing or electronic assembly, even a minute electrostatic discharge (ESD) can destroy sensitive components. Antistatic filter elements work by incorporating materials that dissipate static charges, thereby preventing the accumulation of static electricity that could affect both equipment and processes.

How Antistatic Filter Elements Work

Antistatic filter elements combine traditional filtration techniques with static control properties. Typically, these filters are made from nonwoven fabrics, which are infused with conductive materials such as carbon or metal fibers. These conductive components allow the dissipation of static electricity, facilitating a safer, cleaner environment.

The primary function of an antistatic filter is two-fold it filters out particulate matter such as dust, smoke, and biological contaminants while simultaneously eliminating static charges. This dual functionality is crucial for industries such as pharmaceuticals, where product purity is critical, and electronic manufacturing, where ESD can lead to significant financial losses.

antistatic filter element

Applications of Antistatic Filter Elements

Antistatic filter elements find applications across various sectors. In electronics manufacturing, these filters are used in cleanrooms where the assembly of delicate components occurs. The elimination of static electricity ensures that these components are not damaged during handling and assembly.

In the pharmaceutical sector, antistatic filters help maintain a contaminant-free environment while safeguarding medications from static-related issues. The food industry also benefits from these filters, as they can help maintain hygiene standards while preventing any static-related incidents that could compromise product integrity.

Moreover, antistatic filter elements are widely used in paint booths and powder coating processes, where static electricity can attract dust and other particles to freshly painted surfaces, leading to defects.

Benefits of Antistatic Filter Elements

The utilization of antistatic filter elements offers numerous benefits. First and foremost, these filters enhance product quality by preventing contamination. They also extend the lifespan of machinery by minimizing the risk of static-related damage. Furthermore, they improve worker safety by reducing the chances of electric shock and ensuring compliance with industry regulations concerning ESD.

In summary, antistatic filter elements play a critical role in ensuring clean and safe working environments across various industries. Their ability to filter out contaminants while dissipating static electricity makes them indispensable in settings that require stringent cleanliness and safety standards. As technology continues to advance, the importance of such filtration systems will only grow, underscoring the ongoing need for innovation in air quality management solutions.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: