Tel:

+8615930870079

Tel:

+8615930870079

aug . 08, 2025 03:20 Back to list

Premium Pleated Filter Cartridges for Industrial Dust Collectors

In the relentless pursuit of cleaner air and optimized industrial processes, the pleated filter cartridge dust collector stands as a paramount innovation. As industries worldwide face increasingly stringent environmental regulations and a heightened focus on worker safety and equipment longevity, the demand for highly efficient, durable, and customizable filtration solutions has never been greater. This comprehensive guide delves into the intricate world of these advanced filtration systems, exploring their critical role in modern industrial environments, their underlying technology, and the unparalleled advantages they offer.

Industry Trends and the Evolving Need for Superior Filtration

The landscape of industrial air quality management is rapidly evolving. Driven by global initiatives for sustainable manufacturing, such as the US EPA's National Ambient Air Quality Standards and the European Union's Industrial Emissions Directive (IED), businesses are compelled to adopt more effective dust collection technologies. Traditional bag filters, while still common, are often being supplanted by advanced cartridge filters due to their superior filtration efficiency, smaller footprint, and easier maintenance.

Market analysis indicates a robust growth trajectory for industrial dust collectors, with projections showing the global market reaching over $10 billion by 2027, driven significantly by the adoption of cartridge-based systems. This growth is fueled by an increasing awareness of the health risks associated with airborne particulates, the need to recover valuable dust, and the drive for energy efficiency in dust collection operations. Specifically, the adoption of pleated filter cartridge dust collector systems is on the rise, primarily because they offer higher filtration surface areas in compact designs, leading to improved performance and reduced operational costs compared to traditional methods.

Technical Deep Dive: Understanding the Customized Size Pleated Filter Cartridge Dust Collector

The pleated filter cartridge dust collector is engineered to capture a wide spectrum of airborne particles, from coarse dust to extremely fine particulate matter, including those in the sub-micron range. This high-performance is primarily due to its unique pleated design, which dramatically increases the filter media's surface area within a compact cartridge, allowing for higher airflow rates and longer filter life. The product, "Customized size pleated filter cartridge dust collector," signifies a crucial advantage: the ability to precisely match filtration needs to specific industrial applications, ensuring optimal performance and cost-effectiveness.

Key Technical Parameters and Specifications

Understanding the critical technical specifications is vital for selecting the right pleated filter cartridge dust collector. These parameters dictate the filter's performance, durability, and suitability for various industrial environments. Here's a general overview, though specific values will vary based on customization:

| Parameter | Typical Range / Description | Significance for Pleated Filter Cartridges |

|---|---|---|

| Filter Media Material | Cellulose, Polyester (Spunbond, Non-woven), PTFE membrane, Nanofiber, Blends | Determines filtration efficiency, temperature resistance, chemical compatibility, and dust release properties. Polyester is common for general industrial dust; PTFE/Nanofiber for very fine or sticky dust, and moisture resistance. |

| Filtration Efficiency (MERV / F9-H13) | MERV 10-16 (for industrial dust), F9-H13 (for fine/sub-micron particles) | Measures particle capture capability. High MERV/F9-H13 ratings signify effective capture of `fine cartridge filter for dust extractor` particles, crucial for air quality. Our filters often achieve >99.9% at 0.3 microns. |

| Max Operating Temperature | 80°C - 260°C (176°F - 500°F) | Depends on media. Polyester ~135°C, PTFE ~260°C. Critical for high-temp processes like metal fabrication, furnaces. |

| Pleat Depth & Count | Variable (e.g., 25-50mm depth, 150-300+ pleats) | Directly impacts surface area and dust holding capacity. Higher count/depth for more demanding applications. |

| Surface Area per Cartridge | 5 - 30+ sq meters (50 - 300+ sq ft) | Larger surface area allows more air to flow through with less pressure drop, increasing filter life and energy efficiency. |

| Pressure Drop (Initial) | Typically | Indicates resistance to airflow. Lower initial pressure drop means less energy consumption for the fan. |

| Pressure Drop (Max) | Typically 1000-1500 Pa (4-6 inch W.G.) before cleaning cycle | The point at which the filter needs cleaning or replacement to maintain system performance. |

| Construction (End Caps, Core) | Galvanized steel, Stainless steel, Urethane, PVC | Ensures structural integrity and chemical resistance. Materials selected based on application environment. |

| Cleaning Mechanism Compatibility | Pulse-jet, Reverse Air, Shaker | Our cartridges are primarily designed for efficient pulse-jet cleaning, maximizing dust release and extending filter life. |

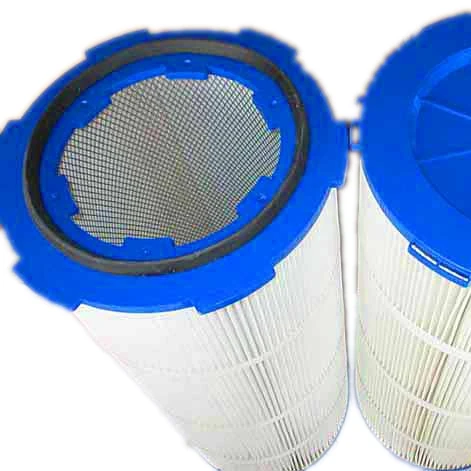

Figure 1: Internal structure of a high-performance pleated filter cartridge dust collector, showcasing the dense pleated media and robust core.

Material and Manufacturing Excellence

The selection of raw materials is paramount to the performance and longevity of a pleated filter cartridge dust collector. We utilize premium-grade filter media such as durable spunbond polyester, highly efficient nanofiber blends, and chemically resistant PTFE membranes. These materials are chosen for their specific properties:

- Polyester Spunbond: Offers excellent abrasion resistance, good chemical resistance, and can withstand temperatures up to 135°C (275°F). Ideal for general industrial dust and light moisture.

- PTFE Membrane (ePTFE): Provides exceptional dust release characteristics and chemical resistance, suitable for sticky dust, high humidity, and corrosive environments, with temperature resistance up to 260°C (500°F). It achieves a very high level of `fine cartridge filter for dust extractor` capabilities.

- Nanofiber: A cutting-edge media with an electrospun layer of nanofibers on a base substrate. This dramatically enhances surface filtration, leading to higher efficiency (e.g., F9-H11) and longer lifespan, especially for sub-micron particles.

Our manufacturing process employs state-of-the-art techniques to ensure product integrity and performance:

Manufacturing Process of Customized Pleated Filter Cartridges

Media Pleating & Cutting

High-precision machines pleat the chosen filter media (e.g., polyester, nanofiber) to a specified depth and count. This process is critical for maximizing surface area and ensuring uniform pleat spacing. Computer Numerical Control (CNC) technology is often employed for precise cutting of the media and end caps, ensuring exact dimensions for a customized fit.

Core/Cage Fabrication

Internal support cores (cages) are fabricated from galvanized steel or stainless steel, depending on the application's corrosion resistance requirements. Spot welding or interlocking techniques ensure robust structural integrity, preventing collapse under differential pressure. This forms the backbone of the pleated filter cartridge dust collector.

End Cap Molding/Attaching

Durable polyurethane or galvanized/stainless steel end caps are molded or stamped. These end caps are then securely attached to the pleated media and core using advanced bonding agents (e.g., specialized hot melts or polyurethanes) or mechanical crimping, ensuring an airtight seal and structural stability. This step is crucial for preventing bypass filtration.

Sealing & Bonding

All seams and connections are meticulously sealed to prevent air leakage and ensure 100% filtration efficiency. This often involves robotic application of sealants and thorough curing processes to guarantee long-term durability, preventing any un-filtered air from escaping.

Quality Control & Testing

Each customized cartridge undergoes rigorous quality control checks. This includes visual inspections, dimensional accuracy verification (adhering to ANSI standards for fitment), media integrity testing, and burst pressure tests to ensure mechanical strength. Filtration performance can be verified against standards like ISO 16890 for ePM (fine particulate matter) efficiency and ISO 2943 for fluid power filter elements, ensuring they meet strict `industrial dust collector cartridge filters` requirements. Our commitment to ISO 9001 certified manufacturing processes underpins our quality assurance.

This meticulous process ensures that every pleated filter cartridge dust collector we produce meets the highest standards of quality and performance, delivering exceptional service life and reliability.

Application Scenarios and Technical Advantages

The versatility of the pleated filter cartridge dust collector makes it indispensable across a broad spectrum of industries, effectively managing diverse dust challenges. Its inherent technical advantages translate directly into significant operational benefits for businesses.

Applicable Industries and Typical Applications:

- Metalworking & Fabrication: Capturing welding fumes, grinding dust, plasma cutting fumes, and abrasive blasting particles. Our cartridges ensure a clean working environment and protect sensitive CNC machinery.

- Pharmaceutical & Chemical Processing: Handling fine powders, active pharmaceutical ingredients (APIs), and chemical dusts. High-efficiency cartridges (`fine cartridge filter for dust extractor`) are critical here to prevent cross-contamination and ensure product purity, often meeting FDA compliance for materials.

- Mining & Aggregates: Managing heavy dust loads from crushing, conveying, and screening operations. Robust, abrasion-resistant filter media extends service life in these demanding environments.

- Woodworking: Collecting sawdust, wood chips, and sanding dust, preventing fire hazards and maintaining clean air.

- Food & Beverage: Filtering food-grade powders and processing dusts, ensuring hygiene and preventing contamination, often requiring specific material certifications.

- Plastics & Composites: Capturing plastic dust, fiberglass, and composite material particulates during cutting, grinding, and molding.

- Cement & Construction: Managing fine cement dust and other construction-related particulates, often requiring specialized media for highly abrasive conditions.

Figure 2: A series of `industrial dust collector cartridge filters` installed in a large-scale manufacturing plant, effectively managing airborne contaminants.

Key Technical Advantages:

- Superior Filtration Efficiency: The pleated design significantly increases surface area, allowing for the capture of finer particles (down to 0.3 microns and below) with higher efficiency compared to traditional bag filters. This results in cleaner exhaust air, often exceeding national and international air quality standards.

- Extended Service Life: Thanks to the larger surface area and efficient pulse-jet cleaning capabilities, our cartridges have a longer operational lifespan. This reduces the frequency of replacements, minimizing maintenance downtime and associated costs. Typical service life ranges from 12-24 months, significantly longer than many alternatives.

- Lower Pressure Drop & Energy Savings: A larger effective filtration area means less resistance to airflow. This translates to a lower initial and operating pressure drop across the filter, reducing the energy consumption of the dust collector fan by up to 30% in some applications. This directly impacts operational expenditure (OpEx), offering substantial cost savings over time.

- Compact Footprint: The high surface area-to-volume ratio of pleated cartridges allows for more filtration capacity in a smaller physical space. This is a crucial advantage for facilities with limited floor space, as it enables the installation of more powerful dust collection systems without expanding the physical plant.

- Easy Maintenance & Installation: Cartridge filters are generally easier and quicker to install and replace than traditional filter bags. This streamlines maintenance procedures, reducing labor costs and operational interruptions. Our designs prioritize user-friendliness for efficient change-outs.

- Versatility in Media Selection: The ability to select from a wide range of filter media (e.g., cellulose, polyester, nanofiber, PTFE) allows for customization based on specific dust characteristics (abrasive, sticky, hygroscopic), temperature, and chemical compatibility requirements, ensuring optimal performance for `industrial dust collector cartridge filters`.

- Cost-Effectiveness: While initial investment might be slightly higher than some alternatives, the long-term benefits of reduced energy consumption, longer service intervals, and lower labor costs for maintenance make the `Customized size pleated filter cartridge dust collector` a more economically viable solution over its operational lifespan.

Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for your pleated filter cartridge dust collector is as critical as selecting the product itself. Our commitment to expertise, experience, authoritativeness, and trustworthiness () sets us apart in a competitive market.

Why Choose Our Customized Solutions? ( Focus)

- Expertise: With over 15 years in the industrial filtration sector, we possess profound knowledge of particle dynamics, filter media science, and dust collector system design. Our engineering team comprises certified filtration specialists who understand the nuances of various industrial processes, ensuring that every customized solution is technically sound and optimized for performance. We speak the language of CFM, micron ratings, and differential pressure, translating complex technical requirements into practical filtration solutions.

- Experience: Our extensive portfolio includes successful installations in diverse industries, from heavy metallurgy to sensitive pharmaceutical production. We have a proven track record of solving unique and challenging dust collection problems. Our case studies demonstrate real-world applications where our customized `industrial dust collector cartridge filters` have delivered measurable improvements in air quality, operational efficiency, and cost savings. Client testimonials consistently highlight our responsiveness and problem-solving capabilities.

- Authoritativeness: We are an ISO 9001:2015 certified manufacturer, underscoring our commitment to rigorous quality management systems. Our products comply with international standards such as ANSI, ASME, and specific industry regulations where applicable. We are proud partners with leading dust collector OEMs and have contributed to industry-specific research, regularly publishing insights on filtration technology. Our long-standing presence and reputation within the global filtration community further solidify our authority.

- Trustworthiness: Transparency, reliability, and customer satisfaction are at the core of our operations. We offer clear warranty commitments (e.g., 1-year standard warranty against manufacturing defects), comprehensive after-sales support, and a dedicated technical assistance team. Our delivery lead times are consistently met, and we provide detailed documentation for every customized order, from material certifications to performance test reports. We are committed to fostering long-term partnerships built on mutual trust.

Product Comparison: Pleated Cartridge vs. Traditional Bag Filter

This table highlights the clear advantages of advanced `industrial dust collector cartridge filters` over traditional bag filters in modern industrial settings.

| Feature | Traditional Bag Filter | Customized Pleated Filter Cartridge |

|---|---|---|

| Filtration Area per Unit | Lower (smaller effective surface area) | Significantly Higher (due to pleating, up to 4x more) |

| Efficiency for Fine Particles | Good, but often requires special media for sub-micron | Excellent (especially with nanofiber/PTFE, `fine cartridge filter for dust extractor`) |

| Pressure Drop (Energy Cost) | Higher, leads to greater fan energy consumption | Lower, resulting in substantial energy savings |

| Footprint Required | Larger collector size for given airflow | Smaller/More Compact (up to 50% smaller footprint) |

| Installation/Replacement Time | Longer, more labor-intensive | Faster, Easier (quick-change mechanisms) |

| Service Life | Typically 6-12 months | 12-24+ months (reduces frequency of change-outs) |

| Dust Release/Cleaning | Can be challenging for sticky dust, residual dust often high | Superior Pulse-Jet Cleaning, excellent dust cake release |

| Cost Over Lifetime | Lower initial, higher OpEx (energy, labor, disposal) | Higher initial, Significantly Lower OpEx (energy, maintenance) |

Customization Solutions

Our core strength lies in providing "Customized size pleated filter cartridge dust collector" solutions. This involves a detailed consultation process to understand your specific operational parameters:

- Application Analysis: We evaluate the type of dust (size, density, abrasiveness, stickiness), air volume (CFM), temperature, humidity, chemical composition of the airstream, and existing dust collector specifications.

- Material Selection: Based on the analysis, we recommend the optimal filter media (e.g., flame-retardant polyester, anti-static media, oleophobic, hydrophilic, PTFE-coated for `fine cartridge filter for dust extractor` or challenging dusts).

- Dimensional Customization: We manufacture cartridges in virtually any length, diameter, and mounting configuration (open/open, open/closed, flange top, tri-lock, etc.) to perfectly fit your existing dust collector housing, regardless of the OEM.

- End Cap & Gasket Materials: Selection of appropriate end cap materials (e.g., galvanized, stainless steel, urethane) and gasket types (neoprene, EPDM, silicone) for chemical compatibility and temperature resistance.

- Special Features: Inclusion of features like internal core pleat supports, external bands, expanded metal outer cages, or specialized coatings for enhanced performance in unique conditions.

Our consultative approach ensures that you receive a filtration solution that is not just a product, but a precisely engineered component designed to seamlessly integrate with your system and optimize its performance for the long haul.

Illustrative Application Cases and Customer Success

The practical application of our `Customized size pleated filter cartridge dust collector` solutions across various industries demonstrates their tangible benefits and our commitment to client success.

Case Study 1: Metal Fabrication Facility – Energy Savings and Reduced Downtime

A large metal fabrication client was struggling with high energy costs and frequent filter changes in their existing baghouse system, which handled welding fumes and grinding dust. Their `industrial dust collector cartridge filters` were becoming clogged too quickly, leading to excessive pressure drops and fan motor strain. After a thorough assessment, we engineered custom-sized polyester pleated cartridges with a specific pleat configuration and a highly efficient pulse-jet cleaning mechanism. The result? A 25% reduction in energy consumption for their dust collection system due to consistently lower pressure drop and an extension of filter life from 6 months to 18 months. This led to significant operational savings and a noticeable improvement in air quality for their workers, directly impacting productivity and compliance.

Figure 3: A manufacturing line benefiting from a robust pleated filter cartridge dust collector system, ensuring clean air for operations and personnel.

Case Study 2: Pharmaceutical Plant – Enhanced Purity and Compliance

A leading pharmaceutical manufacturer required a solution for capturing ultra-fine active pharmaceutical ingredient (API) dust, which demanded extremely high filtration efficiency to prevent cross-contamination and ensure product purity, as well as comply with stringent FDA regulations. We provided a custom-sized `fine cartridge filter for dust extractor` solution utilizing ePTFE membrane media, known for its exceptional sub-micron filtration capabilities and excellent dust release properties. The customized filters not only achieved over 99.99% efficiency for 0.3-micron particles but also significantly extended the cleaning cycles, minimizing product loss during changeovers and ensuring continuous compliance with regulatory standards. This project underscored our capability in delivering precision filtration for highly sensitive applications.

Case Study 3: Cement Production Facility – Durability in Abrasive Environments

A cement plant faced extreme challenges with abrasive cement dust, which rapidly wore down traditional filter bags and led to frequent ruptures. We developed a highly robust `Customized size pleated filter cartridge dust collector` with a specialized, heavy-duty spunbond polyester media, treated for enhanced abrasion resistance and reinforced end caps. Despite the extremely harsh operating conditions, these customized filters demonstrated a service life of 24 months, more than double their previous solutions. The client reported a substantial reduction in filter replacement costs and maintenance labor, along with consistent air quality, even during peak production times.

Frequently Asked Questions (FAQs)

Q1: What is a `pleated filter cartridge dust collector` and how does it work?

A1: A pleated filter cartridge dust collector is a type of industrial air filtration system that uses pleated filter cartridges to capture airborne dust and particulate matter. Air enters the collector, passes through the pleated media where dust is trapped on the surface, and then clean air exits. The pleats vastly increase the surface area, allowing for higher airflow and dust holding capacity in a compact design. Periodically, a pulse-jet system cleans the filters by sending a burst of compressed air to dislodge accumulated dust.

Q2: What are the main advantages of a pleated cartridge filter over a traditional bag filter?

A2: Pleated cartridges offer several advantages: significantly larger filtration surface area in a smaller footprint, leading to higher efficiency, lower pressure drop (resulting in energy savings), longer service life, and easier, quicker maintenance. They are particularly effective as a `fine cartridge filter for dust extractor` applications.

Q3: How do you customize filter cartridges?

A3: Customization involves tailoring dimensions (length, diameter, end cap configuration), filter media type (e.g., polyester, nanofiber, PTFE) based on dust characteristics (size, abrasiveness, stickiness), temperature, humidity, and chemical exposure. We also consider specific industry standards and existing dust collector designs to ensure a perfect fit and optimal performance for `industrial dust collector cartridge filters`.

Q4: What is the typical service life of your customized pleated filter cartridges?

A4: The service life varies greatly depending on the application, dust load, operating hours, and cleaning cycle effectiveness. However, our high-quality `Customized size pleated filter cartridge dust collector` typically offers a service life of 12 to 24 months, often significantly outperforming standard filters due to optimized media and construction.

Q5: What are ISO and ANSI standards and how do they apply to your filters?

A5: ISO (International Organization for Standardization) and ANSI (American National Standards Institute) are international and national bodies that set technical standards. For our filters, this relates to manufacturing quality (e.g., ISO 9001 for quality management systems), filtration performance testing (e.g., ISO 16890 for air filter classification), and dimensional specifications (ANSI for compatible fitment). Adherence to these standards ensures consistent quality, performance, and compatibility.

Q6: Can your filters handle high-temperature applications?

A6: Yes, we offer specialized filter media, such as high-temperature polyester or PTFE membranes, which can withstand continuous operating temperatures up to 260°C (500°F). These materials are specifically chosen for applications like foundries, metal processing, or high-temperature chemical reactions, ensuring the longevity and integrity of the pleated filter cartridge dust collector.

Q7: What is the lead time for customized orders and what is your warranty policy?

A7: Lead times for customized orders typically range from 3-6 weeks, depending on complexity and material availability. We prioritize efficient production while maintaining our stringent quality checks. We provide a standard 1-year warranty against manufacturing defects for our `Customized size pleated filter cartridge dust collector` products, ensuring peace of mind and demonstrating our commitment to quality.

References and Further Reading

For more in-depth information and academic insights into industrial air filtration, consider the following resources:

- "Filtration and Separation Handbook" by Ronald J. Davies (Elsevier) - A comprehensive resource on filtration technologies.

- "Air Pollution Control Engineering" by Noel de Nevers (McGraw-Hill Education) - Provides foundational knowledge on dust collection systems.

- ScienceDirect - Dust Collector Articles: A vast repository of academic papers on various aspects of dust collection and filtration technology.

- ISA (International Society of Automation) - Air Filtration Systems: Discussions and standards related to industrial automation and control in filtration.

- Filtration & Separation Magazine: An industry journal offering insights into new technologies, applications, and market trends in filtration.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: