Tel:

+8615930870079

Tel:

+8615930870079

dec . 20, 2024 10:37 Back to list

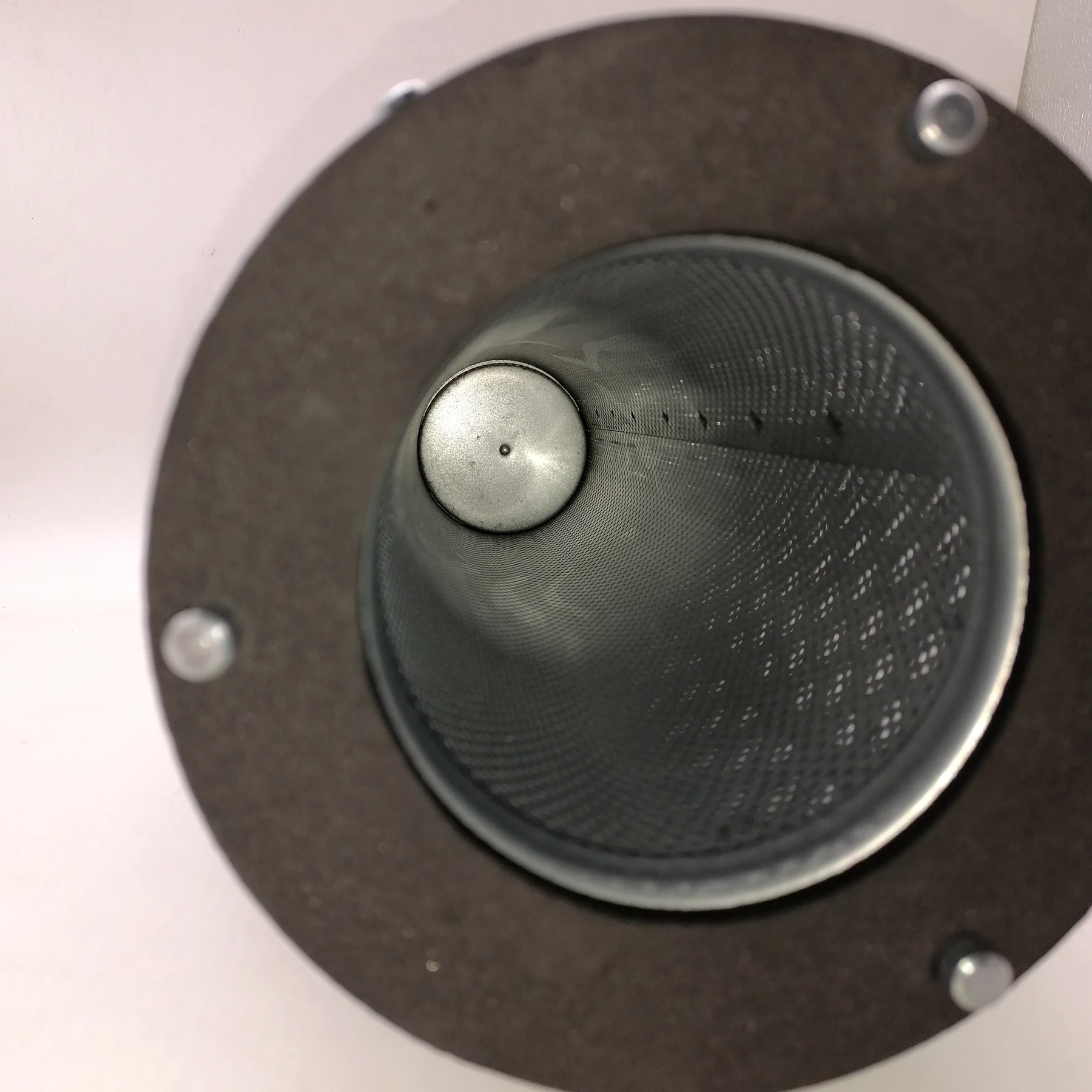

metal filter element

Understanding Metal Filter Elements Their Importance and Applications

Metal filter elements have emerged as a critical component in various industrial applications, offering a reliable solution for filtration needs in harsh environments. These elements are designed to remove contaminants from gases and liquids, ensuring the integrity and efficiency of processes across a multitude of sectors, including automotive, aerospace, chemical processing, and food manufacturing.

What are Metal Filter Elements?

Metal filter elements are porous structures made from various metals, including stainless steel, aluminum, and other alloys. Their primary function is to trap particulates and contaminants, thus maintaining the overall quality of the fluid or gas they filter. These filters can be fabricated in different shapes and sizes to accommodate various system designs, making them versatile for numerous applications.

The manufacturing process typically involves techniques such as sintering, which fuses metal powders under high temperatures to create a durable and porous material. The resulting filters possess high mechanical strength and resilience, making them suitable for demanding environments where traditional filter media may fail.

Advantages of Metal Filter Elements

1. Durability One of the most significant advantages of metal filter elements is their robustness. They can withstand extreme temperatures and pressures, making them ideal for applications in demanding environments, such as chemical processing plants and oil refineries.

2. Reusability Unlike many traditional filters that must be replaced after a certain number of uses, metal filter elements can often be cleaned and reused. This characteristic not only reduces costs but also minimizes waste, contributing to more environmentally friendly practices.

3. High Filtration Efficiency Metal filters can achieve extremely fine filtration levels. The pore size can be precisely controlled during manufacturing, allowing for the removal of very small particles from gases or liquids. This high level of filtration is essential in industries where purity is paramount, such as pharmaceuticals and food processing.

4. Chemical Resistance Many metal filter elements are designed to resist corrosion and chemical attack, enabling their use in aggressive environments. This characteristic is essential for industries that handle corrosive fluids or gases.

metal filter element

5. Versatility These filter elements can be used in various applications, including coolant filtration in machining processes, oil filtration in hydraulic systems, and gas filtration in exhaust systems. Their adaptability makes them suitable for many industrial processes.

Applications of Metal Filter Elements

Metal filter elements are used in a wide array of applications across numerous industries

- Automotive Industry They are often employed in fuel filtration and oil filtration systems, where high efficiency and durability are required to ensure the longevity of engine components.

- Aerospace In the aerospace sector, metal filters are utilized in hydraulic systems and fuel systems to ensure that contaminants do not compromise the performance of crucial systems.

- Food and Beverage In food processing, ensuring the purity of liquids is essential. Metal filter elements are used to prevent contaminants from entering products, thus maintaining the safety and quality of food and beverages.

- Pharmaceuticals The pharmaceutical industry requires stringent filtration standards to produce sterile products. Metal filter elements help achieve necessary purity levels by removing particulates from solutions and gases.

- Chemical Processing Metal filters are crucial in chemical processes for removing solids from bulk liquids and gases, thereby preventing clogging and ensuring smooth operation.

Conclusion

Metal filter elements represent a fundamental technology in many industrial filtration processes. Their durability, reusability, high filtration efficiency, and versatility make them indispensable in applications where quality and safety are paramount. As industries continue to evolve and emphasize sustainability, the role of metal filter elements will likely expand, driving innovations in filtration technology and contributing to cleaner, safer production processes. Understanding the importance and functionality of these elements is crucial for industries seeking efficient filtration solutions.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: