Tel:

+8615930870079

Tel:

+8615930870079

aug . 11, 2025 11:20 Back to list

High-Performance Semi Truck Air Filters for Clean Air

Driving Efficiency: The Critical Role of Advanced Filtration in Heavy-Duty Vehicles

In the demanding world of commercial trucking and public transportation, the longevity and optimal performance of engines are paramount. This is where high-quality air filtration becomes indispensable. Semi truck air filters are not merely components; they are critical barriers protecting complex engine systems from airborne contaminants. Industry trends highlight a growing demand for filters that offer superior filtration efficiency, extended service intervals, and reduced operational costs. With stricter emission regulations and the push for greater fuel economy, the evolution of air purifier cartridge technology, including specialized outer air filter and bus air filter solutions, is accelerating, offering advanced protection against abrasive particles like dust, soot, and pollen, which can severely degrade engine performance and lead to premature wear.

The constant exposure to harsh operating environments, from arid construction sites to urban streets, necessitates robust filtration solutions. According to market analysis, the global automotive air filter market is projected to reach USD 9.5 billion by 2028, growing at a CAGR of over 5% from 2023. This growth is primarily driven by the increasing vehicle parc and stringent emission norms, making the investment in premium filtration systems a strategic imperative for fleet managers and vehicle manufacturers alike. Advanced filter designs are now incorporating multi-layered media, enhanced pleat stabilization, and innovative sealing mechanisms to ensure maximum capture efficiency and minimal bypass, even under extreme conditions. This focus on performance ensures that critical engine components, such as pistons, cylinders, and turbochargers, remain free from harmful abrasives, thereby extending engine life and maintaining peak operational efficiency.

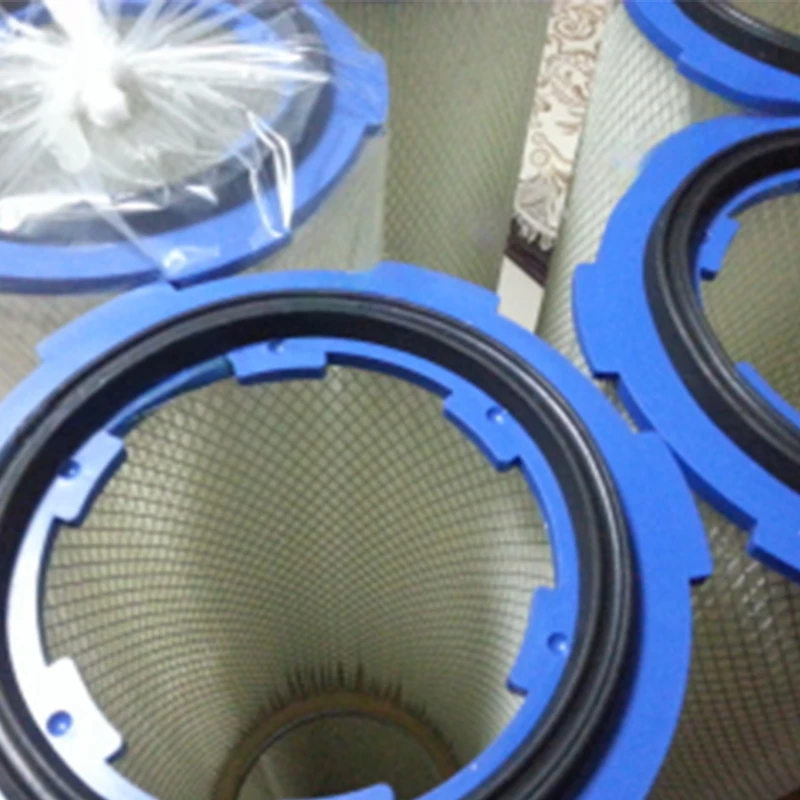

Unveiling the Manufacturing Excellence of Semi Truck Air Filters

The production of high-performance air filters for heavy-duty applications involves a meticulous manufacturing process, emphasizing precision and material science. It typically commences with the selection of premium filtration media, which can range from advanced cellulose blends to highly efficient synthetic fibers. These materials are chosen based on their ability to capture sub-micron particles while maintaining optimal airflow characteristics. The raw media undergoes a pleating process, where it is folded into a specified geometric pattern, often in a "M-pleat" or "V-pleat" configuration, to maximize surface area within a compact design. This increased surface area is crucial for extending dust holding capacity and overall service life. Precision pleating ensures uniform spacing, preventing media collapse and maintaining structural integrity throughout the filter's operational lifespan.

Following pleating, the media pack is securely bonded to robust end caps, often made from durable polyurethane or specialized metal alloys, using advanced sealing technologies to prevent air bypass. The outer housing, typically constructed from corrosion-resistant steel or high-grade plastic, is then integrated to protect the filter element and ensure a perfect fit within the engine's air intake system. Quality control is rigorous at every stage, adhering to international standards such as ISO 9001 for quality management systems and specific filtration test standards like ISO 5011 for measuring filtration performance and dust holding capacity. Products are subjected to stringent tests for pressure drop, burst strength, and filtration efficiency to guarantee compliance with OEM specifications and industry benchmarks. This adherence to detailed manufacturing protocols ensures that each outer air filter and specialized air purifier cartridge meets the rigorous demands of applications in petrochemical, metallurgy, public transportation (bus air filter), and various heavy machinery sectors, delivering consistent performance and extending component life.

Technical Parameters & Performance Benchmarks for Semi Truck Air Filters

Understanding the technical specifications of semi truck air filters is crucial for ensuring optimal engine protection and operational efficiency. Key parameters include filtration efficiency, which is typically measured against specific particle sizes (e.g., 99.9% at 0.3 microns for HEPA-grade or standard efficiency per ISO 5011), and dust holding capacity, indicating how much particulate matter a filter can capture before its performance significantly degrades. Initial pressure drop, a measure of air restriction across the filter, is also vital as a lower initial pressure drop contributes to better fuel economy and reduced strain on the engine. The service life of these filters can vary significantly, often ranging from 30,000 to 100,000 miles or more, depending on the operating environment and filter design. For example, a high-performance outer air filter designed with synthetic media might offer extended service intervals compared to a standard cellulose filter in dusty conditions. This allows for scheduled maintenance, reducing unexpected downtime and associated costs.

| Parameter | Typical Range / Value | Impact on Performance |

|---|---|---|

| Filtration Efficiency (ISO 5011) | 99.5% - 99.9% @ >0.3-5µm | High efficiency minimizes engine wear, extends component life. |

| Dust Holding Capacity | 500g - 2500g (varies by filter size) | Higher capacity means longer service intervals, less frequent replacement. |

| Initial Pressure Drop | < 2.5 kPa (clean filter) | Lower pressure drop improves fuel economy and engine power. |

| Media Type | Cellulose, Synthetic, Blended | Synthetic media often provides higher efficiency and longer life in wet conditions. |

| Service Life | 30,000 - 100,000 miles (or 6-12 months) | Determines replacement frequency, impacting maintenance costs. |

Applications & Operational Advantages of Advanced Filtration

The versatility and robustness of advanced filtration solutions, including `Customization outer air filter air purifier cartridge bus air filter`, make them indispensable across a multitude of heavy-duty applications. In the transportation sector, these filters are critical for long-haul trucks, city buses, and school buses, ensuring consistent engine performance and passenger health through clean cabin air. For instance, a bus air filter equipped with an advanced air purifier cartridge effectively removes particulate matter and allergens, enhancing air quality for passengers. In off-highway applications such as construction, mining, and agriculture, where vehicles operate in extremely dusty and abrasive environments, the durable construction and high dust-holding capacity of a robust outer air filter are essential for preventing premature engine wear and catastrophic failures. Even in stationary power generation or marine engines, where reliability is paramount, specialized semi truck air filters provide the necessary protection against airborne contaminants, safeguarding critical internal components.

The advantages of implementing high-quality filtration extend far beyond mere compliance. Enhanced filtration efficiency directly translates to significant fuel savings, as a cleaner combustion process requires less energy, potentially reducing fuel consumption by 1-3% over the filter's lifespan. This also contributes to lower emissions, aligning with global environmental objectives. Furthermore, the anti-corrosion properties of filter housings and superior sealing mechanisms ensure structural integrity even in humid or chemically aggressive environments, typical in some industrial settings like petrochemical or water treatment plants. By preventing abrasive particles from reaching critical engine components, these filters dramatically extend engine life, reducing the frequency and cost of major overhauls. This results in substantial long-term savings in maintenance costs and increased vehicle uptime, a critical factor for fleet profitability and operational continuity. Customer feedback from large logistics companies often highlights improved engine reliability and reduced unexpected breakdowns as direct benefits of upgrading to premium filtration solutions.

Customization Solutions and Supplier Comparison for Semi Truck Air Filters

The diverse requirements of modern fleets and specialized vehicles often necessitate customized filtration solutions. Our ability to provide a "Customization outer air filter air purifier cartridge bus air filter" is a testament to our adaptable manufacturing capabilities. This involves tailoring filter dimensions, media type, pleat configuration, and end cap materials to precisely match unique engine specifications and operating conditions. Whether it's a specific air purifier cartridge for an older bus model or a robust outer air filter for a next-generation heavy-duty truck, customization ensures optimal fit, maximum performance, and extended service life, which standard off-the-shelf filters may not offer. Our engineering team collaborates closely with clients, leveraging decades of experience to design solutions that integrate seamlessly into existing systems while delivering superior protection and efficiency, often exceeding conventional performance benchmarks. This bespoke approach helps clients address specific challenges, such as extreme dust loading or specialized mounting requirements, directly impacting fleet efficiency.

When evaluating suppliers for semi truck air filters, it is crucial to consider several factors beyond just price. Key aspects include adherence to international certifications like ISO/TS 16949 (now IATF 16949 for automotive quality management), which signifies a commitment to robust quality systems. A supplier's service longevity and partnerships with leading OEMs or fleet operators also reflect their authoritativeness and trustworthiness. We differentiate ourselves through our unwavering commitment to R&D, continuous improvement, and the provision of comprehensive technical support. Unlike some manufacturers who may prioritize volume over bespoke solutions, our focus on customized outer air filter and bus air filter designs, coupled with rigorous testing (validated by third-party labs), ensures that our products not only meet but often exceed industry standards, providing unparalleled value and reliability to our partners across various industrial sectors.

Ensuring Reliability: Quality Assurance, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: How often should semi truck air filters be replaced?

A: Replacement intervals vary based on operating conditions and filter type. Typically, every 30,000 to 100,000 miles or annually, whichever comes first. Refer to your vehicle's OEM manual or consult with our technical support for specific recommendations based on your fleet's environment. - Q: What is the benefit of a synthetic media air filter over cellulose?

A: Synthetic media generally offers higher filtration efficiency, especially for finer particles, and superior moisture resistance, leading to longer service life and better performance in humid or wet conditions compared to traditional cellulose media. - Q: Can your air filters be customized for specific vehicle models or unique applications?

A: Absolutely. Our core strength lies in custom solutions, whether for an outer air filter, an air purifier cartridge, or a specialized bus air filter. We work closely with clients to design filters that precisely fit their unique dimensional, performance, and material requirements.

Delivery & Quality Assurance

Our robust supply chain and manufacturing efficiencies enable competitive delivery cycles for both standard and customized semi truck air filters. Typical lead times for custom orders range from 4-6 weeks after design approval, while standard products are often available for immediate dispatch. Each filter undergoes a rigorous multi-point inspection process, ensuring every unit meets our stringent quality benchmarks and relevant industry standards. Our facilities are ISO 9001 and IATF 16949 certified, reinforcing our commitment to delivering products of uncompromising quality and reliability. This dedication to quality control ensures that our products contribute directly to reducing fleet downtime and extending vehicle lifespan, providing fleet managers with peace of mind.

Warranty & Customer Support

We stand behind the quality of our products with a comprehensive warranty program. All our air filters, including the outer air filter and bus air filter solutions, come with a 1-year or 50,000-mile (whichever comes first) warranty against manufacturing defects. Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-purchase support, ensuring a seamless experience. We pride ourselves on building long-term relationships with our clients, offering expert advice and prompt assistance to maximize the performance and longevity of their heavy-duty vehicle fleets. Our commitment extends beyond the sale, providing ongoing support to ensure optimal filter performance throughout its service life.

Conclusion & Outlook

The role of advanced air filtration in safeguarding the performance and extending the lifespan of heavy-duty vehicle engines cannot be overstated. From the intricate manufacturing processes ensuring superior filtration media and structural integrity to the meticulous quality control and customization capabilities, every aspect of our semi truck air filters is designed with the B2B decision-maker in mind. By choosing high-quality air purifier cartridge, outer air filter, and bus air filter solutions, fleet operators can significantly reduce maintenance costs, improve fuel efficiency, comply with environmental regulations, and enhance overall operational reliability. Our commitment to expertise, experience, authoritativeness, and trustworthiness ensures that every product delivers consistent, verifiable performance. As the industry continues to evolve, demanding even greater efficiency and reduced environmental impact, advanced air filtration will remain at the forefront of engine protection technology.

References

- International Organization for Standardization. ISO 5011:2014 Road vehicles — Filter elements for air filters for internal combustion engines — Test method for assessing filtration performance.

- Society of Automotive Engineers. SAE J726: Air Cleaner Test Code.

- Filtration and Separation Magazine. "Advances in Air Filtration Media for Heavy Duty Applications." Vol. 57, No. 3, 2020.

- Market Research Future. "Automotive Air Filter Market Research Report – Global Forecast till 2028." Published 2023.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: