Tel:

+8618931101301

Tel:

+8618931101301

nov . 21, 2024 06:28 Back to list

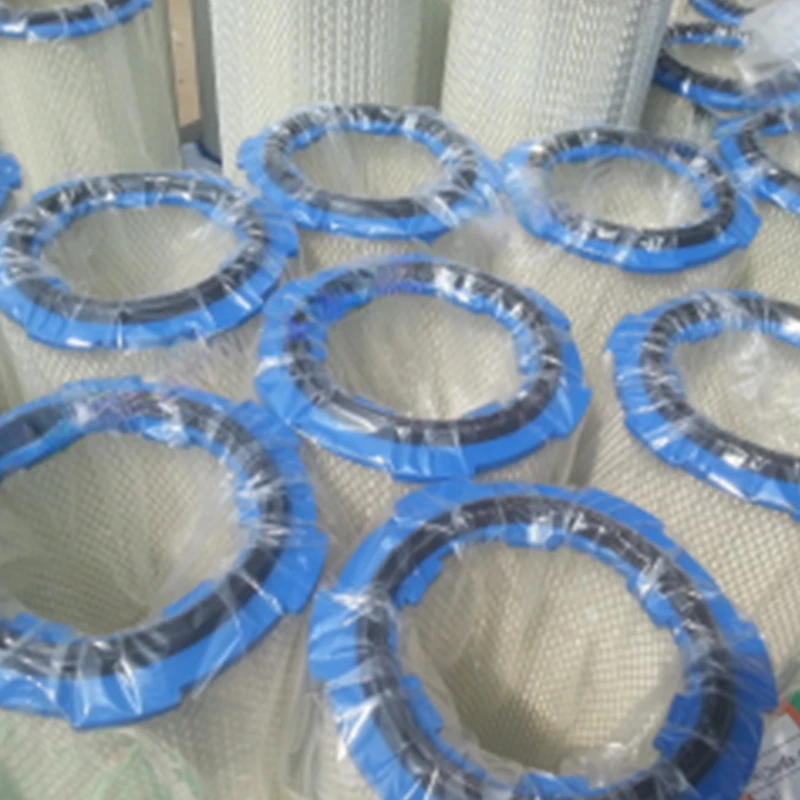

dust extractor pleated filter cartridges

Understanding Dust Extractor Pleated Filter Cartridges A Comprehensive Guide

In various industries, managing dust and particulate matter is crucial not only for maintaining a clean work environment but also for ensuring compliance with health and safety regulations. One effective solution that has gained popularity is the use of dust extractor pleated filter cartridges. These cartridges play a vital role in enhancing the efficiency of dust collection systems, ensuring the longevity of equipment, and protecting the health of workers. This article explores the importance of pleated filter cartridges, their advantages, and considerations for selection and maintenance.

What Are Dust Extractor Pleated Filter Cartridges?

Pleated filter cartridges are designed specifically for dust extraction applications. They consist of a cylindrical filter media that is pleated to increase the surface area. This pleating allows the cartridge to trap more dust and particulate matter compared to traditional filter elements, leading to improved filtration efficiency and lifespan. The pleated structure also minimizes resistance to airflow, ensuring that air can move freely through the system without causing strain on the dust extractor.

Advantages of Using Pleated Filter Cartridges

1. Increased Filtration Efficiency The pleated design significantly expands the surface area of the filter, which enhances its ability to capture smaller particles. This increased efficiency is essential in various industries, including woodworking, pharmaceuticals, and metalworking, where fine dust can pose serious health risks.

2. Longer Lifespan Due to their larger surface area, pleated filter cartridges generally have a longer life compared to standard filters. This longevity translates to reduced maintenance frequency and lower replacement costs over time.

3. Better Airflow These cartridges are designed to allow for optimal airflow, which means that dust extractors can operate more efficiently. Lowering the resistance helps reduce energy consumption, making the system more cost-effective.

4. Versatility Pleated filter cartridges come in various materials and configurations, allowing them to be used in a wide range of applications. Whether it’s capturing fine dust in a woodworking shop or managing fume extraction in a manufacturing facility, there is a suitable pleated filter available.

5. Ease of Replacement The modular nature of pleated filter cartridges makes them easy to install and replace. This convenience reduces downtime and labor costs associated with maintenance.

Selecting the Right Pleated Filter Cartridge

dust extractor pleated filter cartridges

When choosing a dust extractor pleated filter cartridge, several factors must be considered

- Filtration Requirement Determine the specific type and size of particles you need to capture. The Efficiency Rating of the filter is a crucial factor in this decision.

- Compatibility Ensure that the cartridge is compatible with your existing dust extraction system. Checking the dimensions and fitting specifications is essential to avoid installation issues.

- Material Composition Consider the materials used in the filter media. For example, synthetic media may provide better durability and moisture resistance compared to cellulose materials.

- Operating Conditions Assess the environmental conditions where the dust extractor will operate. Factors like temperature, humidity, and chemical exposure can impact the performance and durability of the filter.

Maintenance Tips

To maximize the performance and lifespan of pleated filter cartridges, routine maintenance is essential

- Regular Inspection Regularly check filters for signs of wear, damage, or clogging, and replace them as needed.

- Cleaning Depending on the application, some filters may be cleaned and reused. However, always refer to the manufacturer's guidelines to avoid damaging the filter.

- Monitoring Airflow Keep an eye on the airflow rates; a drop could indicate that the filter is clogged and needs attention.

In conclusion, dust extractor pleated filter cartridges are a vital component of effective dust management systems in various industries. Their efficiency, longevity, and ease of use make them an excellent investment for maintaining a safe and clean working environment. By understanding their benefits and ensuring proper selection and maintenance, businesses can significantly enhance their operational effectiveness while protecting the health of their workforce.

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

Email:

Email: