Tel:

+8618931101301

Tel:

+8618931101301

dec . 15, 2024 07:18 Back to list

cartridge dust collector filter

The Importance of Cartridge Dust Collector Filters

In today’s industrial landscape, maintaining a clean and safe working environment is paramount. One of the critical components contributing to this goal is the cartridge dust collector filter. These filters play an essential role in capturing airborne particulate matter, ensuring that manufacturers comply with health and safety regulations while simultaneously enhancing operational efficiency.

What are Cartridge Dust Collector Filters?

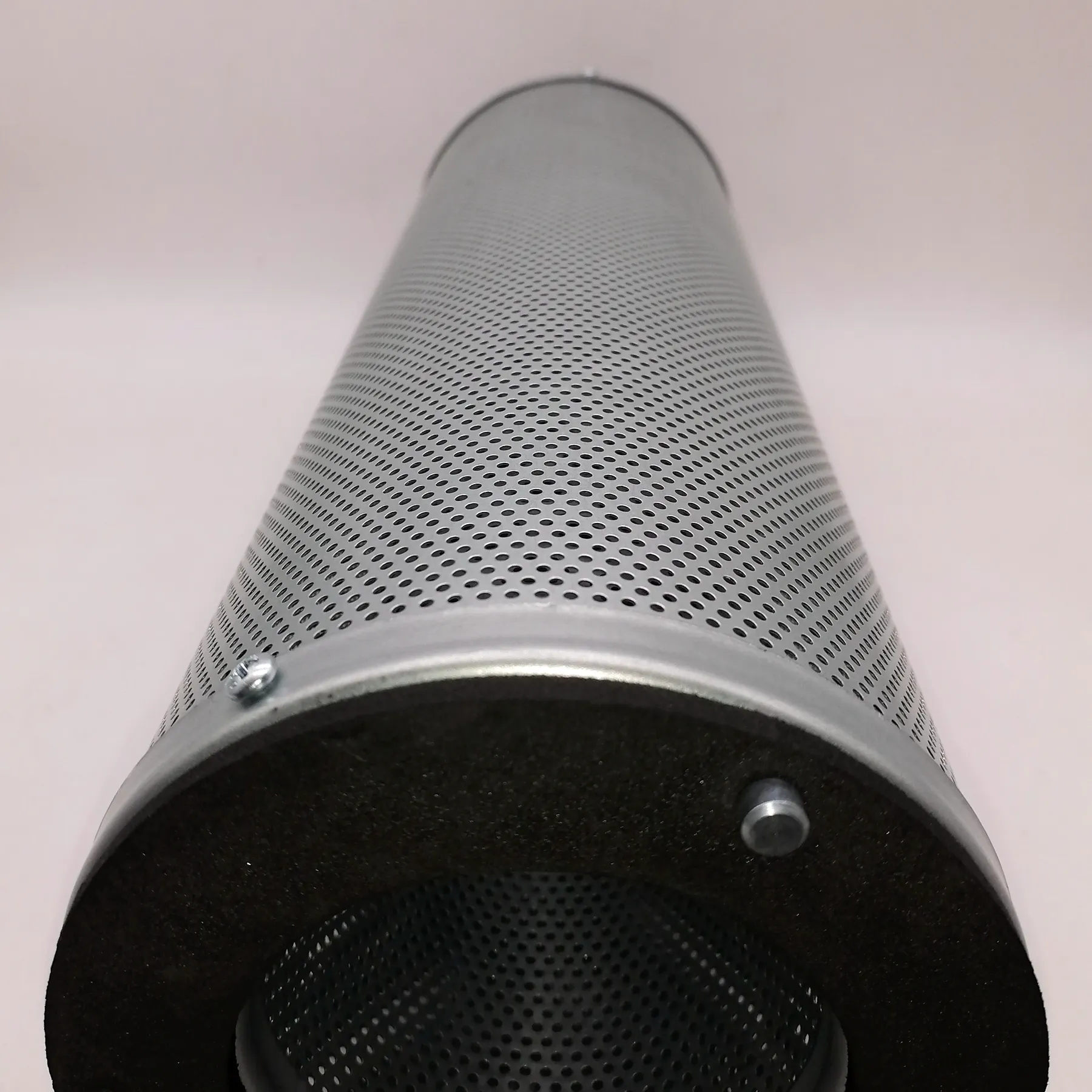

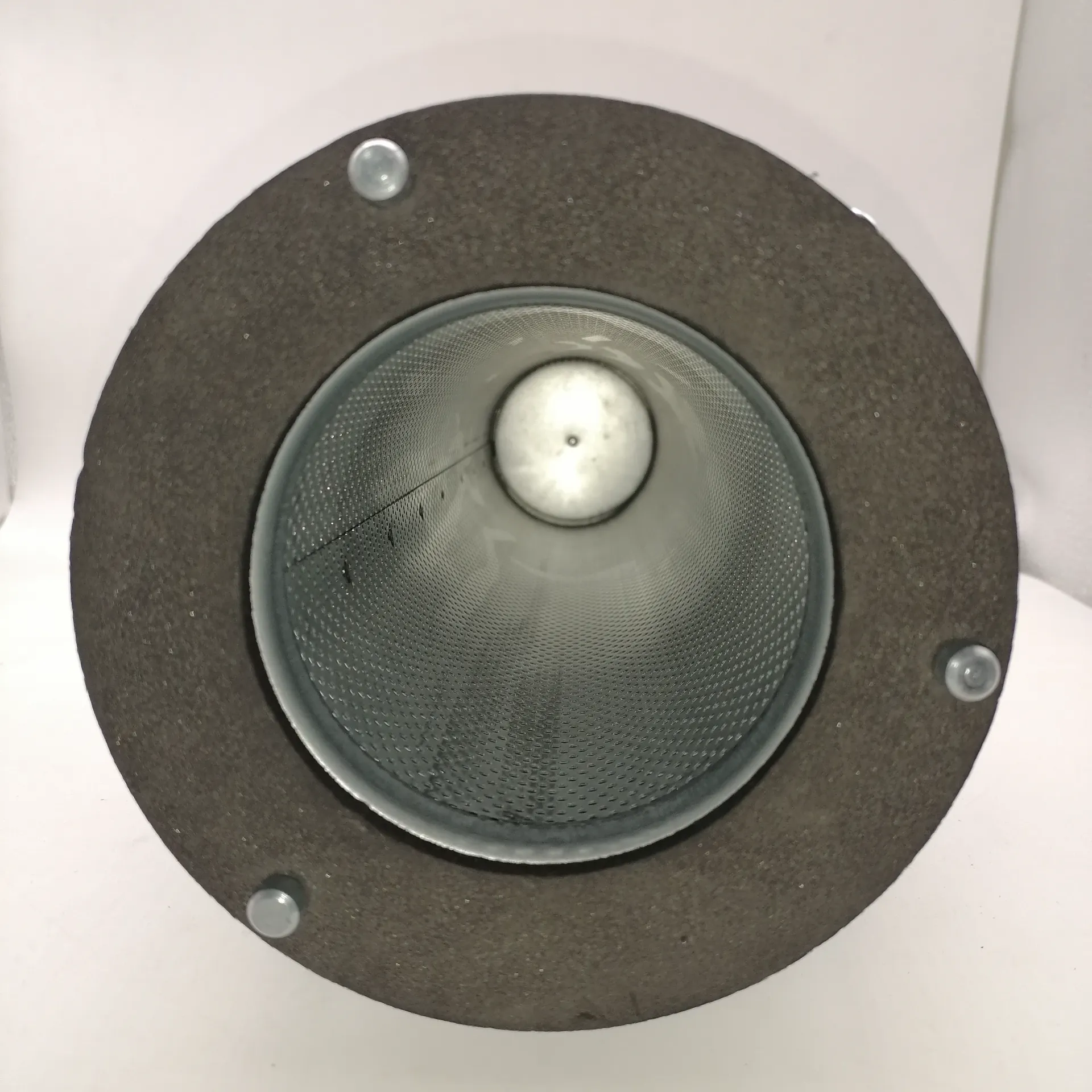

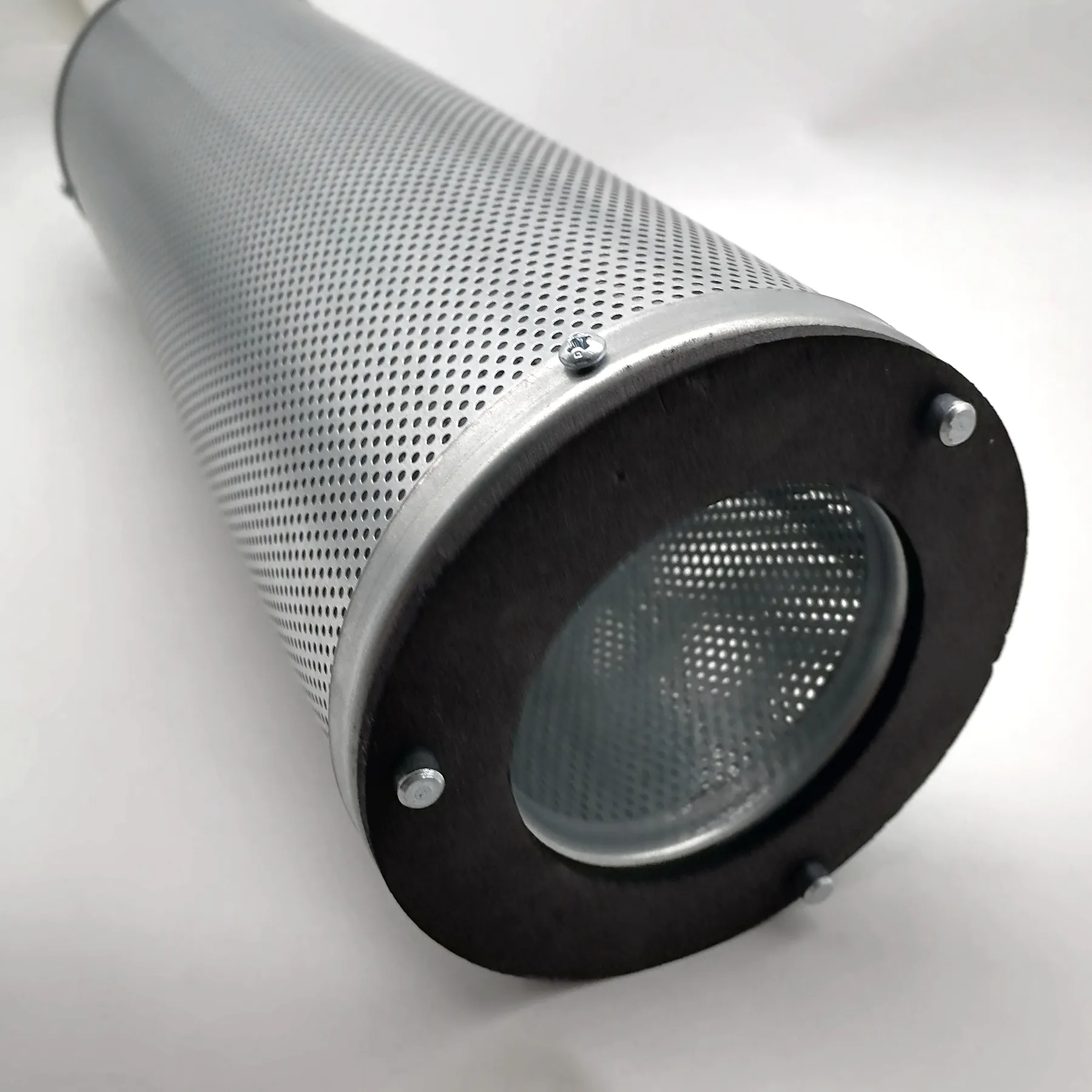

Cartridge dust collector filters are advanced filtration devices designed to remove dust and other particulate matter from the air in industrial environments. They consist of cylindrical filter elements that provide a large surface area for capturing particulates without clogging quickly. Typically made from materials such as polyester, fiberglass, or other synthetic fibers, cartridge filters are designed to withstand harsh conditions and ensure long-lasting performance.

How They Work

The functioning of cartridge dust collector filters relies on several key processes. When air containing dust and particulates is drawn into the collector, the airflow passes through the filter cartridges. Larger particles are trapped on the surface, while smaller particles can penetrate deeper into the filter media. Over time, as the filter collects dust, it creates a dust cake on its surface. This dust cake actually enhances the filter's efficiency, acting as a barrier to finer particles. Periodic cleaning pulses, often using compressed air, remove the accumulated dust, ensuring that airflow remains optimal and the filter's lifespan is extended.

Applications Across Industries

Cartridge dust collector filters are utilized in a variety of industries, ranging from woodworking and metal processing to food production and pharmaceuticals. In woodworking, for instance, dust from sanding and cutting operations can be hazardous to workers and can also pose a fire risk. The use of cartridge filters helps mitigate these risks by capturing wood chips and fine dust.

In the metalworking industry, grinding and sanding processes generate substantial amounts of dust that can affect air quality and machinery performance. Cartridge filters are essential for maintaining a safe and clean environment while ensuring compliance with regulations.

cartridge dust collector filter

The food and pharmaceutical industries also rely heavily on efficient dust collection systems. In these sectors, maintaining product purity and avoiding contamination is crucial. Cartridge dust collector filters help ensure that airborne contaminants do not compromise the quality of the final products.

Benefits of Cartridge Filters

The adoption of cartridge dust collector filters presents numerous benefits for industries. First and foremost, they provide effective particulate capture, which helps in maintaining a clean working environment. This is essential not only for employee health but also for equipment longevity. Dust accumulation can lead to machinery malfunctions and increased maintenance costs, so having a reliable dust collection system is economically advantageous.

Moreover, cartridge filters often have a smaller footprint compared to traditional bag filters, making them suitable for facilities with limited space. Their high efficiency and low energy consumption also contribute to a sustainable operational model, aligning with modern eco-friendly practices.

Maintenance and Care

While cartridge dust collector filters are robust, they do require regular maintenance to operate efficiently. This includes periodic inspections, cleaning, and timely replacement of filter cartridges when they are no longer effective. Developing a maintenance schedule based on the operational demands and dust generation levels is critical to ensure the system's optimal performance.

Conclusion

In conclusion, cartridge dust collector filters are an indispensable element in modern industrial operations. By effectively capturing airborne dust and particulates, they enhance workplace safety, protect equipment, and contribute to regulatory compliance. As industries continue to focus on health, safety, and sustainability, the role of cartridge dust collector filters will undoubtedly become even more significant. Investing in high-quality filtration systems is not merely a matter of compliance; it is a commitment to the well-being of employees and the integrity of the production process itself. As technology advances, we can anticipate even more efficient designs and materials that will further enhance the performance of these vital systems.

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

Email:

Email: