Tlf.:

+8615930870079

Tlf.:

+8615930870079

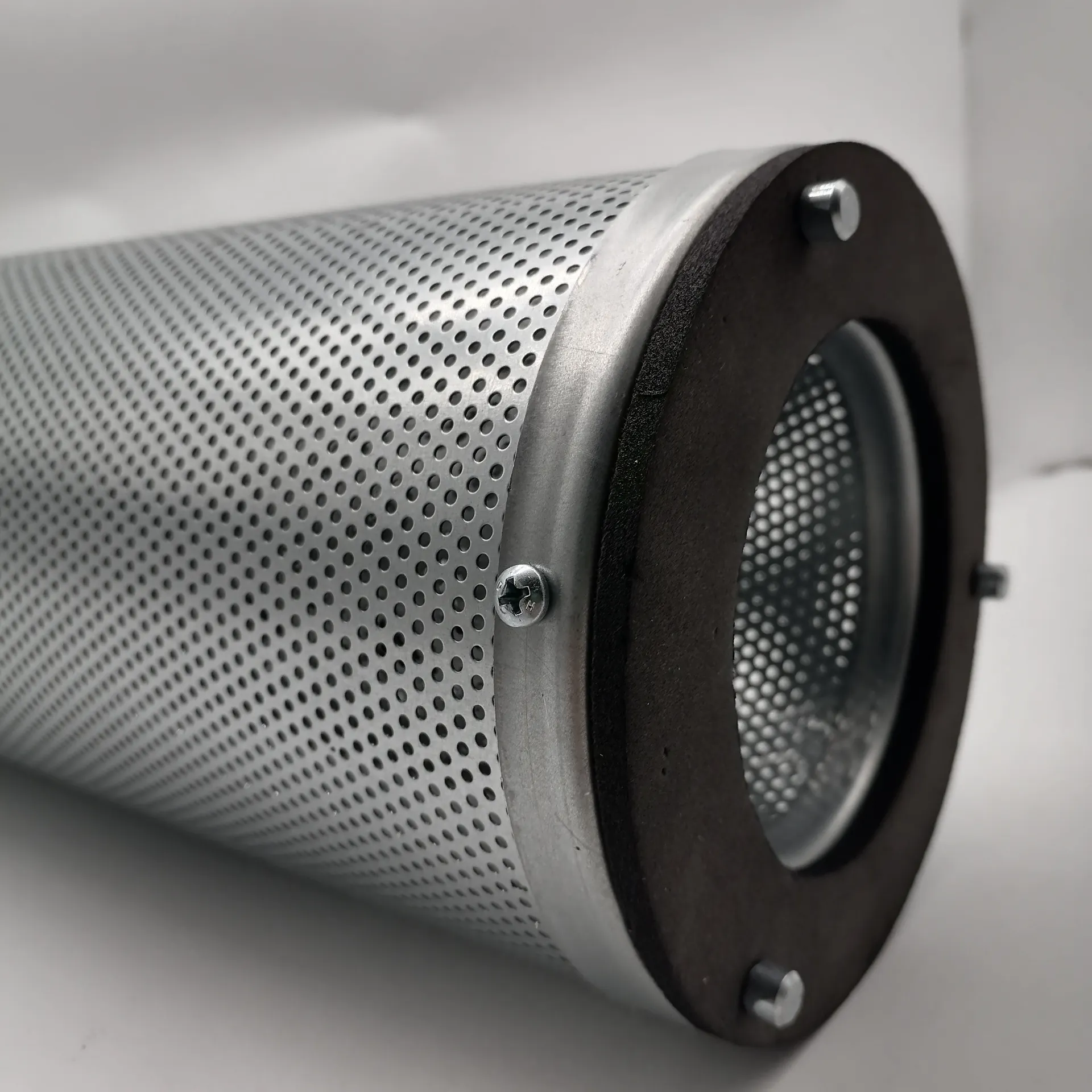

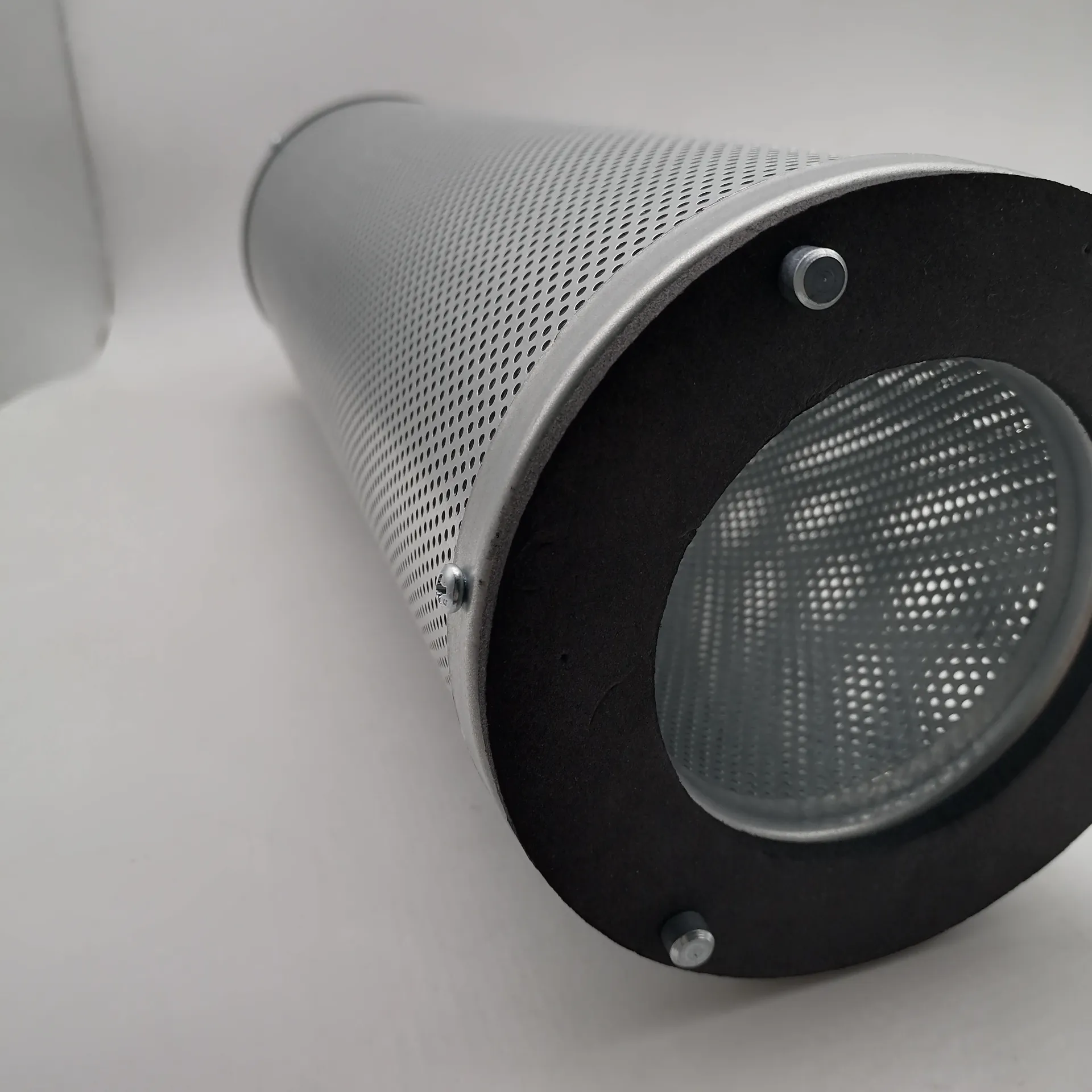

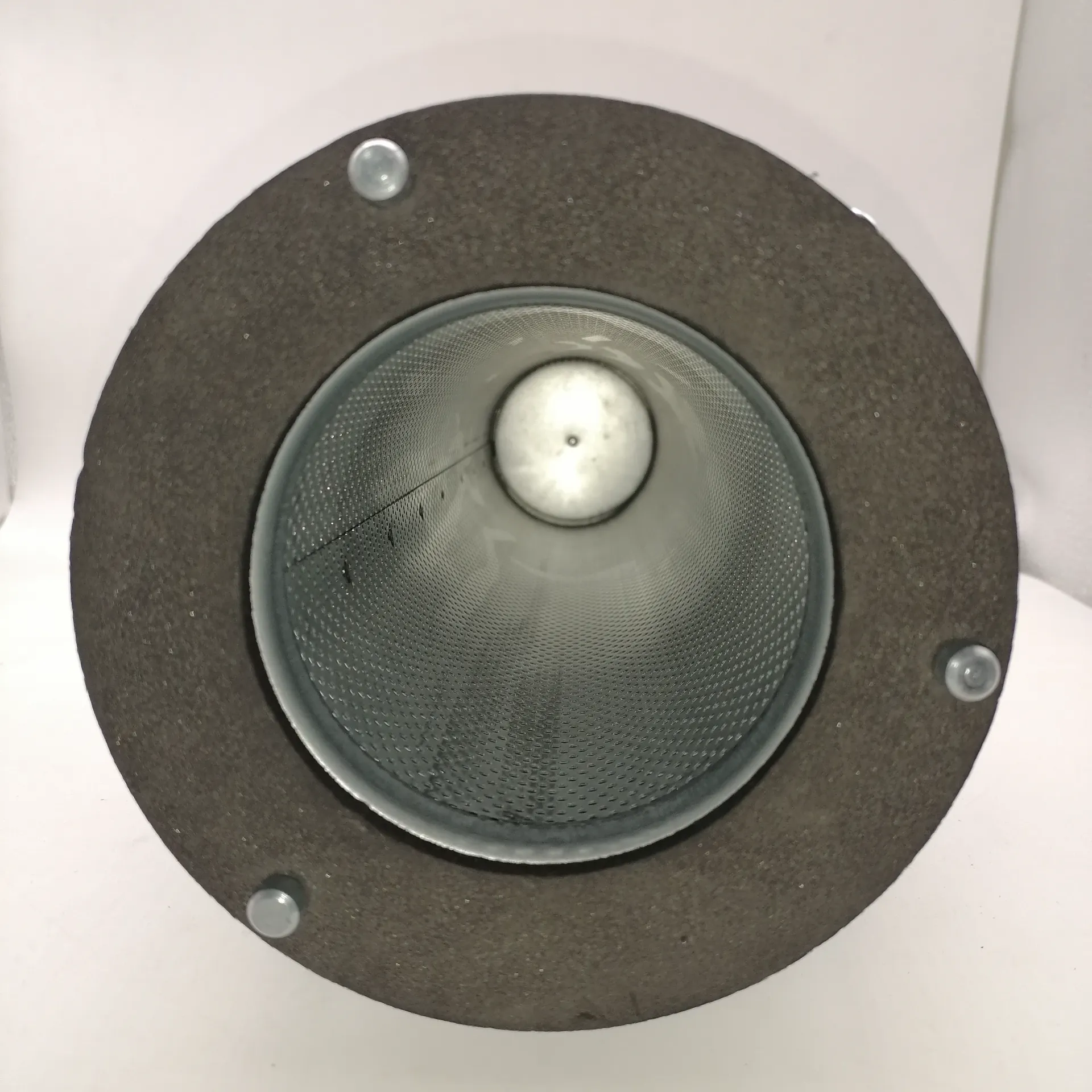

Aktivt kulfilterpatron er en effektiv luftrensningskomponent, der hovedsageligt bruges til at adsorbere og fjerne forurenende stoffer som organisk damp, lugt, røg og skadelige gasser i luften. Dets kernemateriale er aktivt kul, et specialbehandlet kulstofholdigt materiale med en højt udviklet porestruktur og et stort specifikt overfladeareal, hvilket giver det en stærk adsorptionskapacitet.

Funktionsprincippet for aktivt kulfilterpatron er baseret på den fysiske adsorption og kemiske adsorptionsmekanisme for aktivt kul. Fysisk adsorption refererer til aktivt kul, der fanger forurenende stoffer i luften gennem sin porøse struktur, mens kemisk adsorption involverer reaktionen mellem kemiske grupper på overfladen af aktivt kul og forurenende stoffer. Denne dobbelte adsorptionsmekanisme gør det muligt for filterpatronen med aktivt kul at udvise fremragende ydeevne til at fjerne skadelige stoffer i luften.

Aktivt kulfilterpatroner bruges i en lang række applikationer, og de bruges almindeligvis i industrielle ventilationssystemer, laboratorier, medicinske faciliteter, kontorer og hjem. I disse miljøer hjælper filterpatroner med aktivt kul med at forbedre luftkvaliteten og beskytte folks sundhed, samtidig med at de hjælper med at opfylde de strenge standarder for luftrensning i visse industrier.

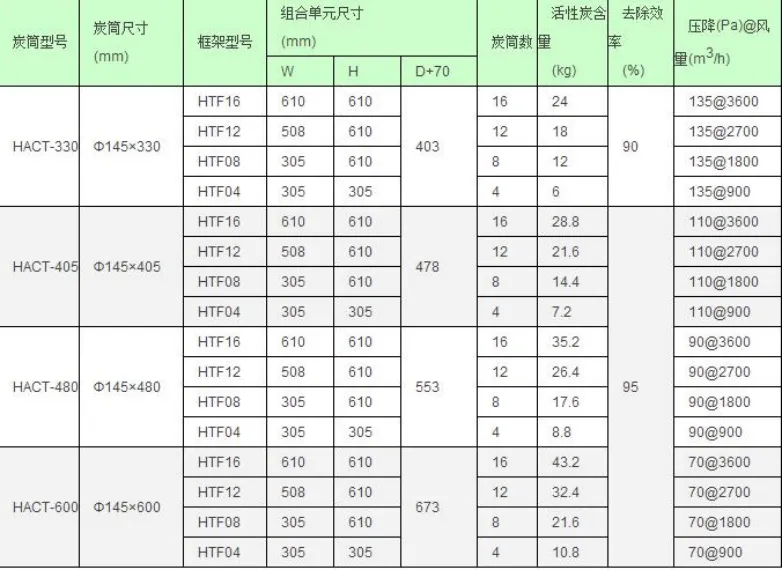

===Ydeevnefunktioner===

◆ Brug af granulært aktivt kul behandlet med speciel kemisk formel

◆Stærk adsorptionskapacitet, høj fjernelseseffektivitet og pålidelig ydeevne

◆Nem at installere og vedligeholde, lave driftsomkostninger

◆ Udskiftelige adsorptionsmedier, metalskal kan genbruges

◆Rammer kan leveres og samles og bruges i henhold til den nødvendige gasbehandlingskapacitet.

◆ Filterpatronmaterialet kan være galvaniseret stålplade eller rustfrit stål

◆Rammematerialet kan være koldvalset stålplade spraybelagt eller rustfrit stål

===Ansøgning===

◆Specialdesignet til kommerciel eller industriel central klimaanlæg og centraliserede ventilationssystemer til at fjerne lugte (stank) og skadelige gasser i luften

◆ En række specielle aktiverede kulmaterialer kan leveres i henhold til de faktiske behov, såsom flygtige organiske forbindelser, sure og alkaliske gasser, formaldehyd, kviksølvdamp, radioaktive gasser.

Factory-Customized HEPA Activated Carbon Cartridges: Core Introduction

ONLY TECHNOLOGY, a leading air filter factory, presents factory-customized HEPA activated carbon cartridges—innovative solutions that merge the precision of HEPA filter cartridge technology with the adsorption power of activated carbon. As a versatile air filter cartridge, these units redefine comprehensive purification, addressing both particulate matter and gaseous contaminants in a single, tailored design.

At their core, these cartridges combine two critical filtration mechanisms. The HEPA filter cartridge layer, rated H13 or H14, captures 99.97% of particles as small as 0.3 microns—including dust, pollen, bacteria, and fine industrial aerosols—ensuring exceptional particulate removal. Complementing this, an activated carbon layer adsorbs volatile organic compounds (VOCs), odors, formaldehyde, and gaseous pollutants, making the cartridge far more versatile than standard air filter cartridge models that focus solely on particles or gases.

As a customized air filter, these cartridges are engineered to fit your exact needs. Our air filter factory offers extensive customization: dimensions (to match specific equipment), HEPA grade (adjusted for filtration intensity), carbon type (coconut shell, coal-based, or impregnated for targeted gases), and casing materials (galvanized steel, aluminum, or food-grade plastic). Whether retrofitting legacy systems or integrating with new air purifiers, HVAC units, or industrial machinery, they eliminate the inefficiencies of off-the-shelf filters.

Durability and performance are built into every component. The HEPA filter cartridge media is pleated to maximize surface area and airflow, while the activated carbon is evenly distributed to prevent channeling—ensuring consistent adsorption across the cartridge’s lifespan. The robust casing, a hallmark of our air filter factory’s craftsmanship, resists moisture, temperature fluctuations, and mechanical stress, making these cartridges suitable for harsh environments like laboratories, medical facilities, and manufacturing plants.

Their applications span diverse sectors. In healthcare, they maintain sterile air in operating rooms by trapping pathogens and neutralizing chemical odors. In industrial settings, they pair with ventilation systems to remove both metal dust and solvent fumes. In commercial spaces, they enhance indoor air quality by addressing allergens and volatile compounds from furniture or cleaning agents. As a customized air filter, they adapt seamlessly to each scenario, proving their versatility beyond basic air filter cartridge functions.

Backed by our air filter factory’s expertise, these cartridges undergo rigorous testing to meet ISO 14644 and EN 1822 standards, ensuring reliability and compliance. Easy to install and replace, they minimize downtime while maintaining peak performance. For businesses seeking a single solution to complex air purification challenges, these factory-customized HEPA-activated carbon cartridges deliver unmatched efficiency—proving that precision, customization, and comprehensive protection can coexist in one powerful air filter cartridge.

Performance Features of This Factory-Customized HEPA Activated Carbon Cartridge: Efficiency & Durability

ONLY TECHNOLOGY’s factory-customized HEPA-activated carbon cartridges stand out as a high-quality filter with performance features that redefine efficiency and durability in air purification. As a specialized industrial air filter, they deliver unmatched contaminant removal while withstanding the rigors of demanding environments—qualities that make them a benchmark for reliability.

Efficiency is engineered into every layer. The integrated HEPA component captures 99.97% of particles as small as 0.3 microns, from industrial dust to airborne pathogens, while the activated carbon layer adsorbs 95%+ of VOCs, formaldehyde, and odors. This dual-action ensures a single customized air filter handles both particulate and gaseous pollutants, eliminating the need for multiple systems. Even at high airflow rates (up to 1,200 m³/h), pressure drop remains low (≤200 Pa), ensuring HVAC and ventilation systems operate efficiently without energy waste—a critical advantage for industrial settings.

Durability is a hallmark of this high-quality filter. The casing, crafted from galvanized steel or stainless steel, resists corrosion, temperature extremes (-30°C to 120°C), and mechanical stress, outlasting plastic alternatives in factories, laboratories, and outdoor installations. The HEPA media is pleated and reinforced to prevent tearing, while the activated carbon is securely bonded to avoid channeling (uneven airflow that reduces efficiency). These design choices extend service life to 6–12 months in heavy-use scenarios, reducing replacement frequency compared to standard industrial air filter models.

Customization enhances both traits. As a customized air filter, it adapts to specific needs: thicker carbon layers for high-VOC environments boost adsorption capacity, while higher-grade HEPA (H14) elevates particle removal for clean room applications. Reinforced frames for high-pressure systems ensure durability in industrial ventilation, proving that tailored design directly improves performance.

Backed by rigorous testing, this industrial air filter meets global standards (ISO 14644, EN 1822), ensuring consistent efficiency across batches. As an air filter exporter, ONLY TECHNOLOGY guarantees this reliability worldwide, with cartridges performing seamlessly in climates from humid factories to arid industrial zones.

In essence, these cartridges merge the efficiency of a precision-engineered high-quality filter with the ruggedness required of an industrial air filter. Their durability minimizes maintenance costs, while their efficiency reduces energy use—making the customized air filter a cost-effective solution for long-term operations. For industries prioritizing performance that endures, this is the definitive choice.

Efterlad din besked

E-mail:

E-mail: